A kind of flame retardant organic electrolytic solution and rechargeable zinc battery for rechargeable zinc battery

An organic electrolyte and zinc battery technology, which is applied in the manufacture of electrolytes, secondary batteries, and electrolyte batteries, etc., can solve the problems of volatile, flammable electrolyte, and high toxicity, and achieve reduced growth, excellent flame retardancy, and inhibition of decomposition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] In a high-purity argon atmosphere, 0.25 g NaClO 4 Sodium salt and 0.51 g Zn(CF 3 SO 3 ) 2 Dissolve the zinc salt in 2 mL of LTMP flame-retardant organic solvent, shake it fully, and ultrasonicate for 10 minutes at room temperature to completely dissolve the salt, and make it into 1 mol / L NaClO 4 + 0.7 mol / L Zn(CF 3 SO 3 ) 2 -TMP electrolyte.

[0050] Gained electrolyte is carried out following performance test:

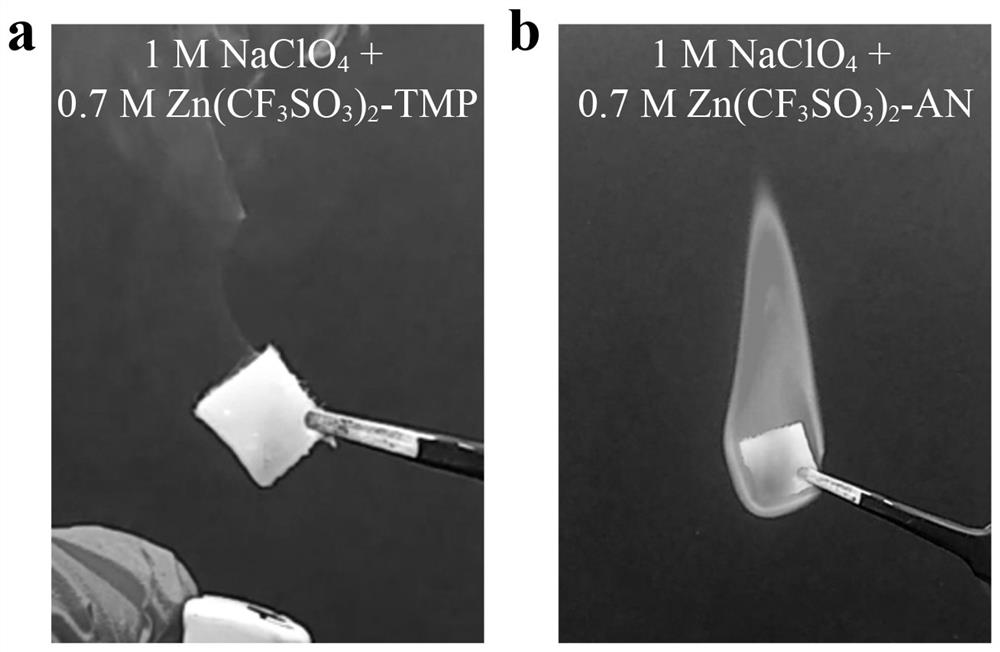

[0051] (1) Flame retardant performance

[0052] Ignition test: use a lighter to ignite the fire-resistant cotton soaked in the electrolyte prepared in this embodiment, and observe its burning condition.

[0053] figure 1 The ignition test results of a show that the flame-retardant organic electrolyte prepared in this example cannot be ignited by an open flame at all, and has a good flame-retardant effect.

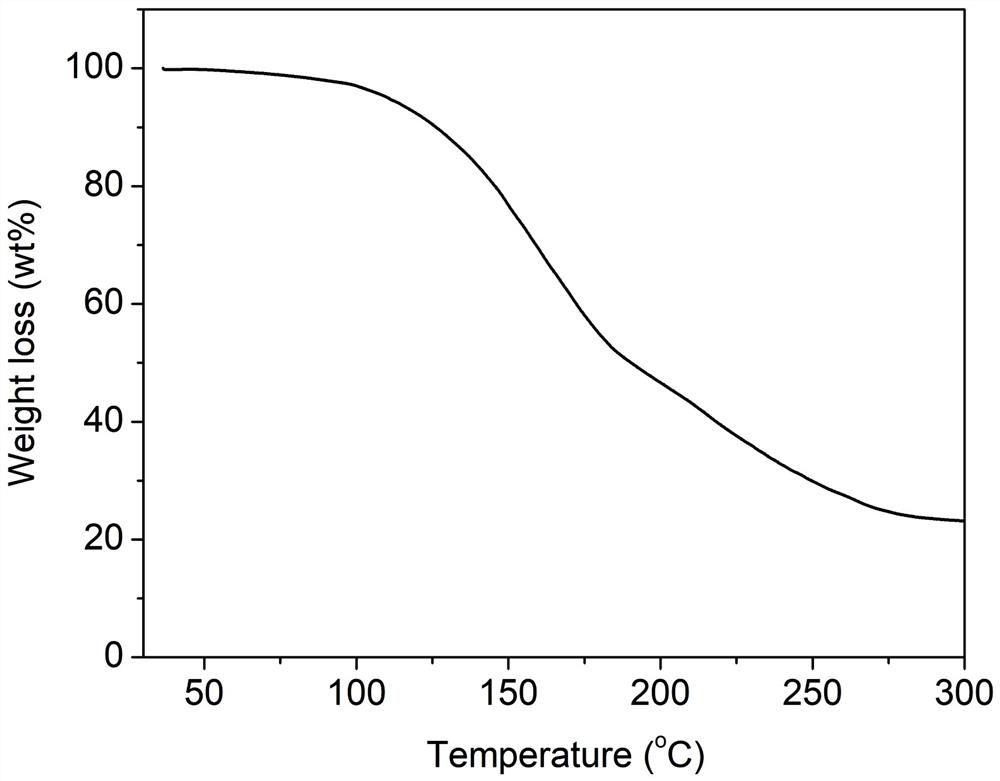

[0054] Thermal stability test: for the flame retardant organic electrolyte (1 mol / L NaClO 4 + 0.7 mol / L Zn(CF 3 SO 3 ) 2 -TMP) for thermograv...

Embodiment 2

[0072] In a high-purity argon atmosphere, 0.49 g NaClO 4 Sodium salt and 0.51 g Zn(CF 3 SO 3 ) 2 Dissolve the zinc salt in 2 mL of LTMP flame-retardant organic solvent, shake it fully, and ultrasonicate for 1 hour at room temperature to completely dissolve the salt and prepare it as 2 mol / L NaClO 4 + 0.7 mol / L Zn(CF 3 SO 3 ) 2 -TMP electrolyte. The obtained electrolyte was tested for flame retardancy, thermal stability, electrical conductivity and electrochemical performance.

[0073] The electrolyte in this example is applied to a rechargeable zinc battery, and the preparation method is as follows: in a pure argon environment, use the prepared Na 3 V 2 (PO 4 ) 2 o 2 F The positive electrode sheet was used as the positive electrode, the zinc foil with a diameter of 12 mm was used as the negative electrode, and the glass fiber membrane was used as the separator. 80 μL of the electrolyte of this example was added dropwise, and the battery was packaged to prepare a zin...

Embodiment 3

[0076] In a high-purity argon atmosphere, 0.085 g NaClO 4 Sodium salt and 0.363 g Zn(CF 3 SO 3 ) 2 Dissolve the zinc salt in 1 mL of LTMP flame retardant organic solvent, shake it fully, and ultrasonicate for 15 minutes at room temperature to completely dissolve the salt, and make it into 0.7 mol / L NaClO 4 + 1 mol / L Zn(CF 3 SO 3 ) 2 -TMP electrolyte. The obtained electrolyte was tested for flame retardancy, thermal stability, electrical conductivity and electrochemical performance.

[0077] The electrolyte in this example is applied to a rechargeable zinc battery, and the preparation method is as follows: in a pure argon environment, use the prepared Na 3 V 2 (PO 4 ) 2 o 2 F The positive electrode sheet was used as the positive electrode, the zinc foil with a diameter of 12 mm was used as the negative electrode, and the glass fiber membrane was used as the separator. 80 μL of the electrolyte of this example was added dropwise, and the battery was packaged to prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com