Heat pipe-cooled mixed fuel reactor system

A technology for mixing fuels and reactors, applied in reactors, cooling devices, reducing greenhouse gases, etc., can solve problems such as poor safety, accidental shutdown of the core, and low heat exchange efficiency, so as to improve inherent safety and achieve emergency shutdown. , The effect of high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

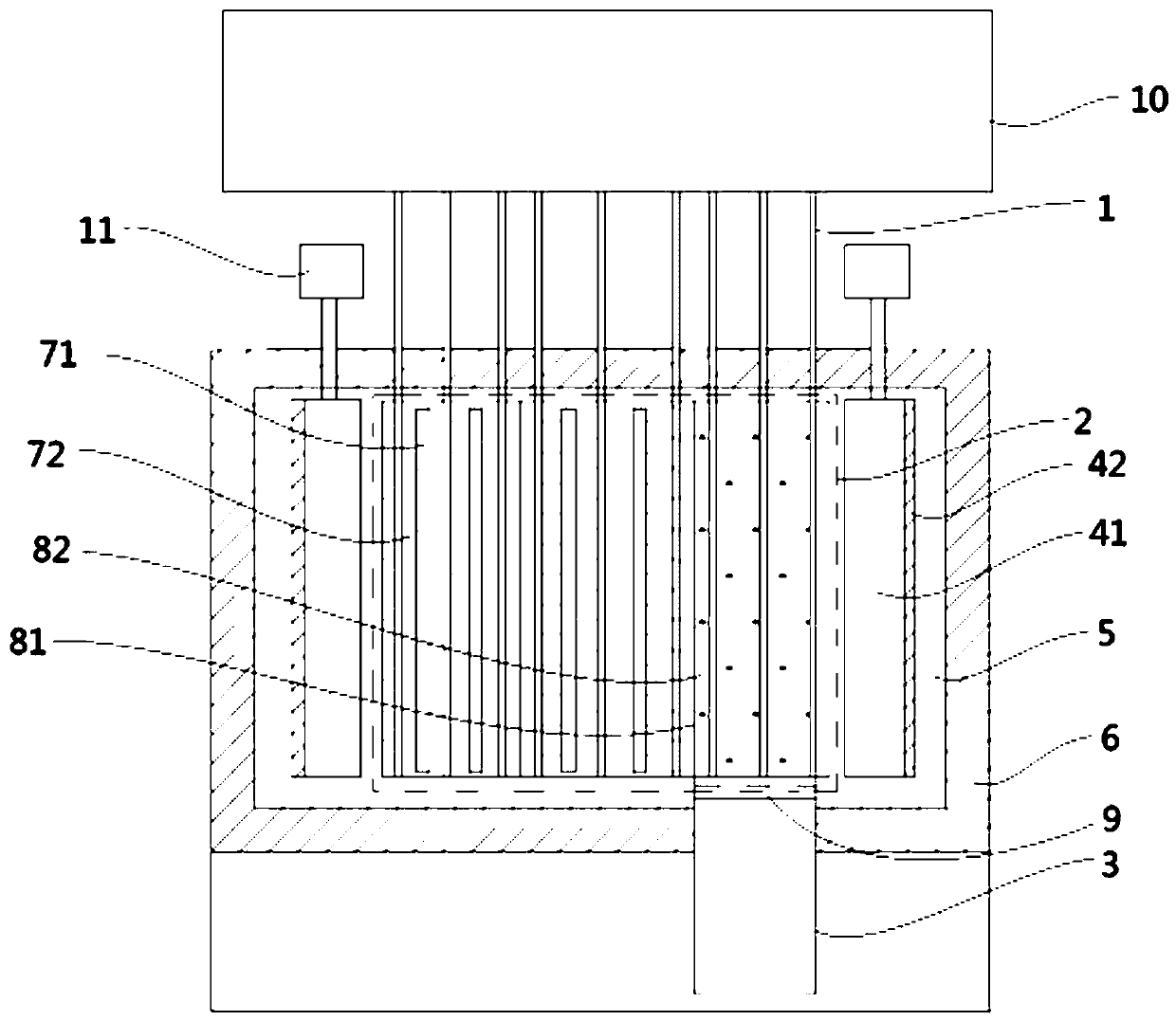

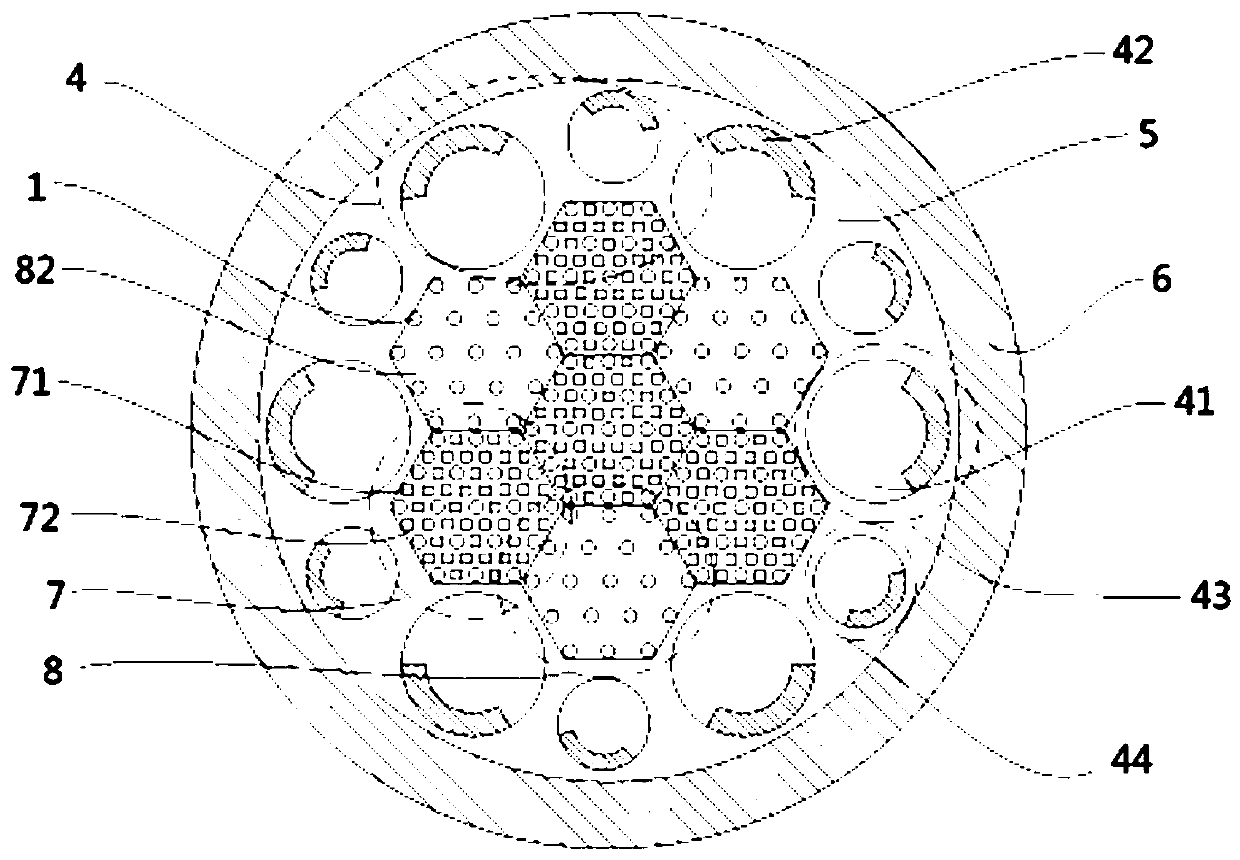

[0030] A heat pipe cooled mixed fuel reactor system such as figure 1 and 2 As shown, the reactor core includes a core active area 2, a liquid storage tank 3, a control drum 4, a reflective layer 5 and a core barrel 6; wherein the core active area 2 is composed of a plurality of hexagonal fuel assemblies, many The root heat pipes 1 are evenly distributed inside the fuel assembly; the reflective layer 5 is located outside the core active area 2, and a plurality of symmetrically arranged control drums 4 are arranged inside the reflective layer 5; the liquid storage tank 3 is arranged below the core active area 2.

[0031] The core active area 2 is composed of two fuel assemblies, a solid fuel assembly 7 and a liquid fuel assembly 8. The two fuel assemblies have the same size and are of a hexagonal prism structure; the solid fuel assembly 7 includes a fuel element 71, a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com