Fluorescence detection method for phthalate plasticizer in oil substance

A technology of phthalate and ester plasticizer, applied in the field of detection, can solve the problems of many chemical reagents, unsuitable phthalate content detection, complicated operation steps, etc., and achieves low cost, The detection conditions are mild and easy to control, and the operation is convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A method for detecting the content of phthalates in sesame oil by using the method of the invention.

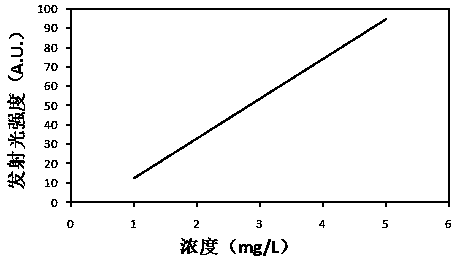

[0018] (1) Preparation of phthalate standard curve Weigh 1mg, 2mg, 3mg, 4mg, and 5mg of phthalate standard products into 5 numbered 1L volumetric flasks, and dilute to volume with triglyceride. It is configured as a series of phthalate standard solutions with gradient distribution. Then pipette 1mL from the standard solutions of the five 1L volumetric flasks into sequentially numbered 20mL containers, add 10mL of 10% NaOH solution to all containers, and then place all containers in a water bath and stir at a constant temperature at 90°C until Evaporate the liquid to dryness, fully saponify the sample to be tested, fully hydrolyze the phthalate contained in it into sodium phthalate and alcohol, then cool to room temperature, then add 10mL deionized water to the container respectively, stir, and make A small amount of sodium phthalate generated in the container is fully...

Embodiment 2

[0025]The method adopts the method of the invention to detect the content of phthalates in edible oil.

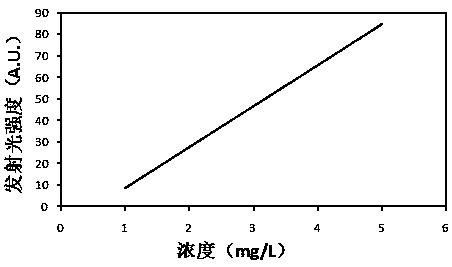

[0026] (1) Preparation of phthalate standard curve Weigh 1, 2, 3, 4, and 5 mg of phthalate standard products into 5 numbered 1L volumetric flasks, dilute to volume with triglyceride, It is configured as a series of phthalate standard solutions with gradient distribution. Then pipette 1mL from the standard solutions of the five 1L volumetric flasks into sequentially numbered 20mL containers, add 10mL of 10% NaOH solution to all containers, and then place all containers in a water bath and stir at a constant temperature at 100°C until Evaporate the liquid to dryness, fully saponify the sample to be tested, fully hydrolyze the phthalate contained in it into sodium phthalate and alcohol, then cool to room temperature, then add 10mL deionized water to the container respectively, stir, and make A small amount of sodium phthalate generated in the container is fully dissolved in w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com