Impregnation device and method for preparing copper-clad laminated board

A technology of copper-clad laminates and dipping tanks, which is applied in the processing of textile materials, processing textile material carriers, textiles and papermaking, etc. It can solve the problem of reducing the electrical insulation of copper-clad laminates, limiting the length of glass fiber cloth, and affecting production efficiency. problems, to achieve the effect of improving the impregnation effect, not easy to deviate, and preventing deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

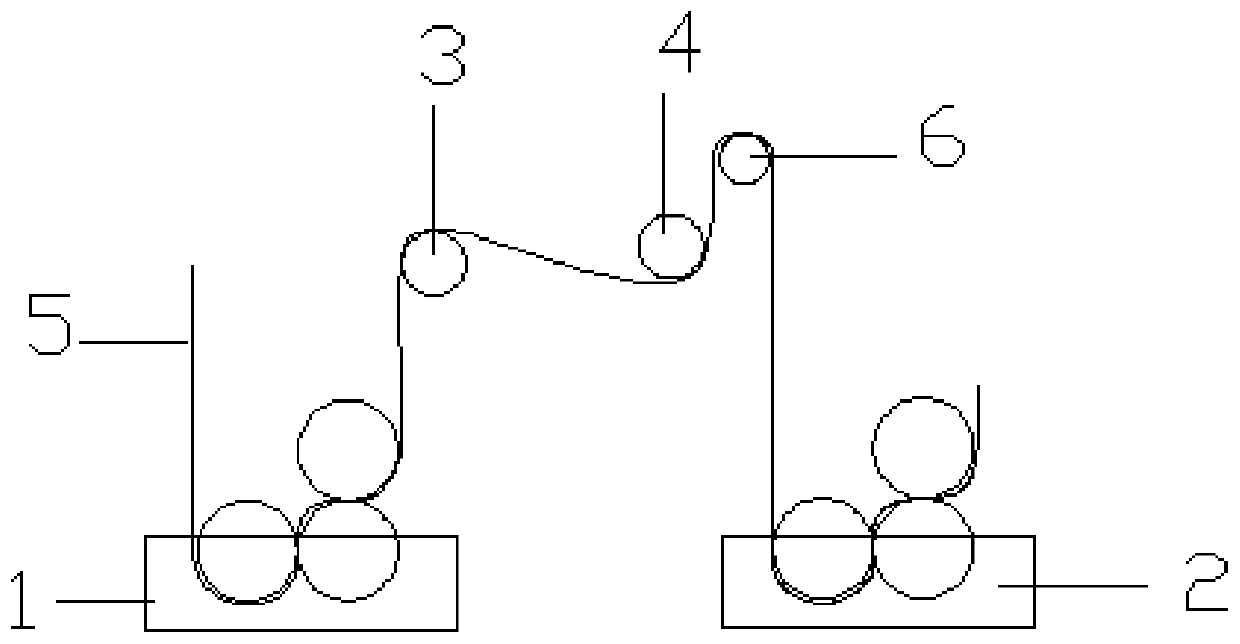

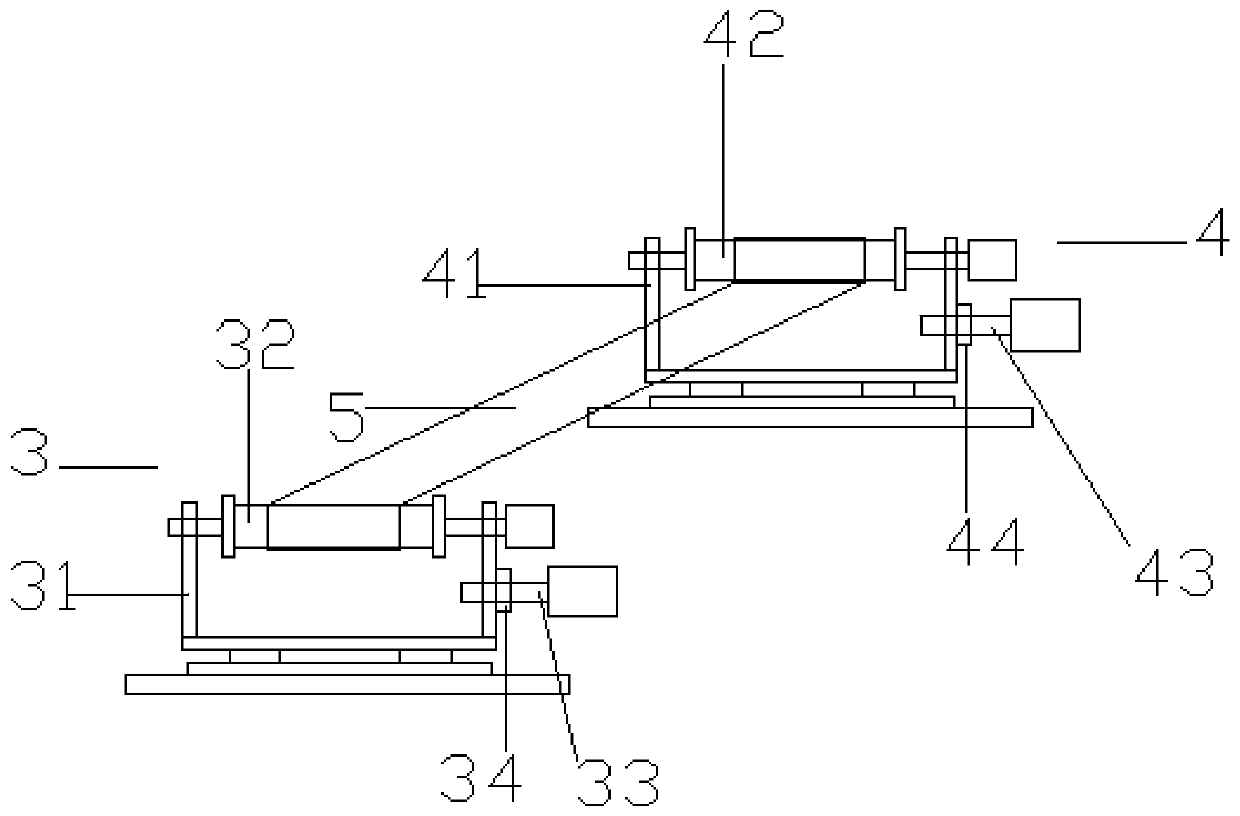

[0028] Figure 1-Figure 2 An impregnation device for preparing copper-clad laminates is shown, the impregnation device includes a water-soluble resin impregnation tank 1, a hydrophobic resin impregnation tank 2, a tensioning mechanism 3, a roller 6, a winding mechanism 4, and a glass fiber Cloth 5, the glass fiber cloth 5 passes through the water-soluble resin impregnation tank 1, the tension mechanism 3, the take-up mechanism 4, the roller 6 and the hydrophobic resin impregnation tank 2 in sequence,

[0029] Water-soluble resin is housed in the water-soluble resin impregnation tank 1, the first roller group is arranged in the water-soluble resin impregnation tank 1, and the glass fiber cloth 5 passes between the first roller group and the The tensioning mechanism 3 is connected;

[0030] The hydrophobic resin impregnated tank 2 is filled with a hydrophobic resin, and the hydrophobic resin impregnated tank 2 is provided with a second roller group, and the glass fiber cloth 5 ...

Embodiment 2

[0041] An impregnation method for preparing a copper-clad laminate, the method comprising the following steps:

[0042] Step 1. The glass fiber cloth is impregnated once in the water-soluble resin impregnation tank through the first roller group;

[0043] Step 2. The glass fiber cloth after primary impregnation transmits the signal to the controller through the action of the first sensor, the second sensor, the third sensor and the fourth sensor on the tensioning mechanism and the winding mechanism, and the controller controls the first The motor and the second motor adjust the coiling frame and the tensioning frame;

[0044] Step 3: The glass fiber cloth coming out of the output end of the coiling mechanism is introduced into the hydrophobic resin impregnation tank through the roller, and is impregnated twice through the action of the second roller group and the hydrophobic resin to complete the impregnation.

[0045] The water-soluble resin is water-soluble phenolic resin. ...

Embodiment 3

[0048] An impregnation method for preparing a copper-clad laminate, the method comprising the following steps:

[0049] Step 1. The glass fiber cloth is impregnated once in the water-soluble resin impregnation tank through the first roller group;

[0050] Step 2. The glass fiber cloth after primary impregnation transmits the signal to the controller through the action of the first sensor, the second sensor, the third sensor and the fourth sensor on the tensioning mechanism and the winding mechanism, and the controller controls the first The motor and the second motor adjust the coiling frame and the tensioning frame;

[0051] Step 3: The glass fiber cloth coming out of the output end of the coiling mechanism is introduced into the hydrophobic resin impregnation tank through the roller, and is impregnated twice through the action of the second roller group and the hydrophobic resin to complete the impregnation.

[0052] The water-soluble resin is an alkylphenol resin.

[0053...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com