Biomass dry distillation type cracking furnace

A pyrolysis furnace and biomass technology, applied in the field of dry distillation, can solve the problems of high labor intensity of operators, low production efficiency, pollution of the surrounding atmospheric environment, etc., and achieve the effect of improving the production operation environment, improving work efficiency, and increasing the cracking speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

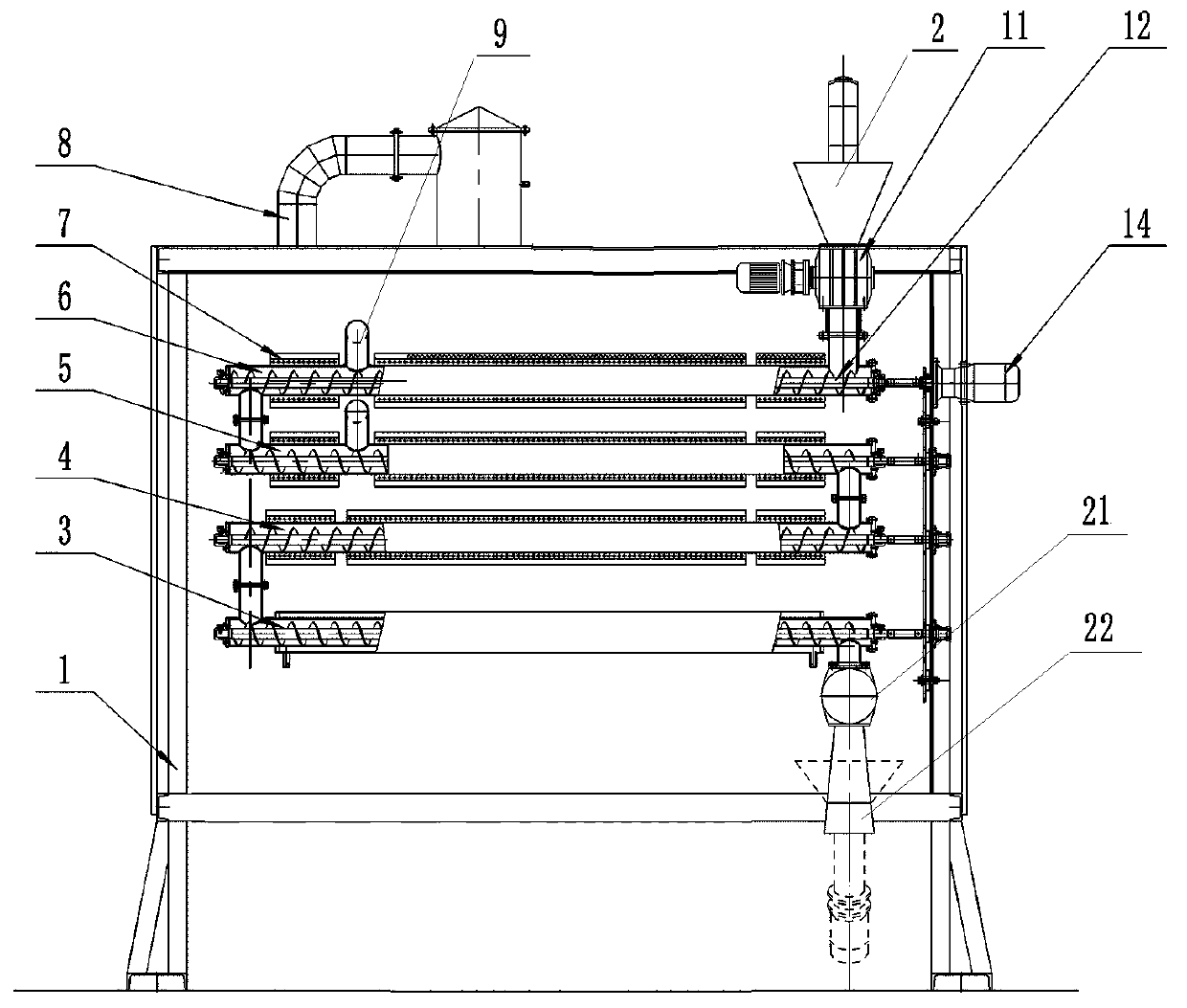

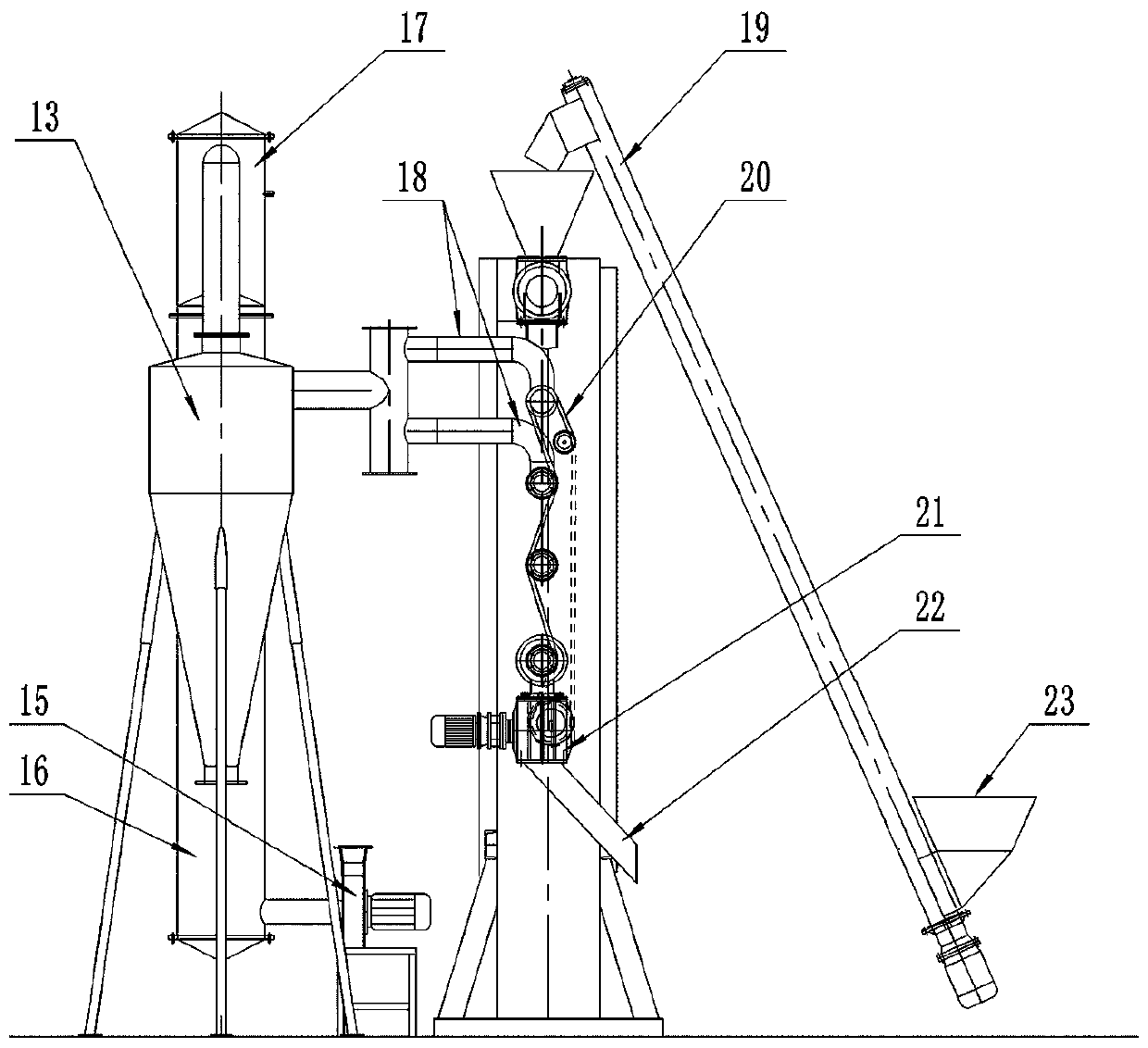

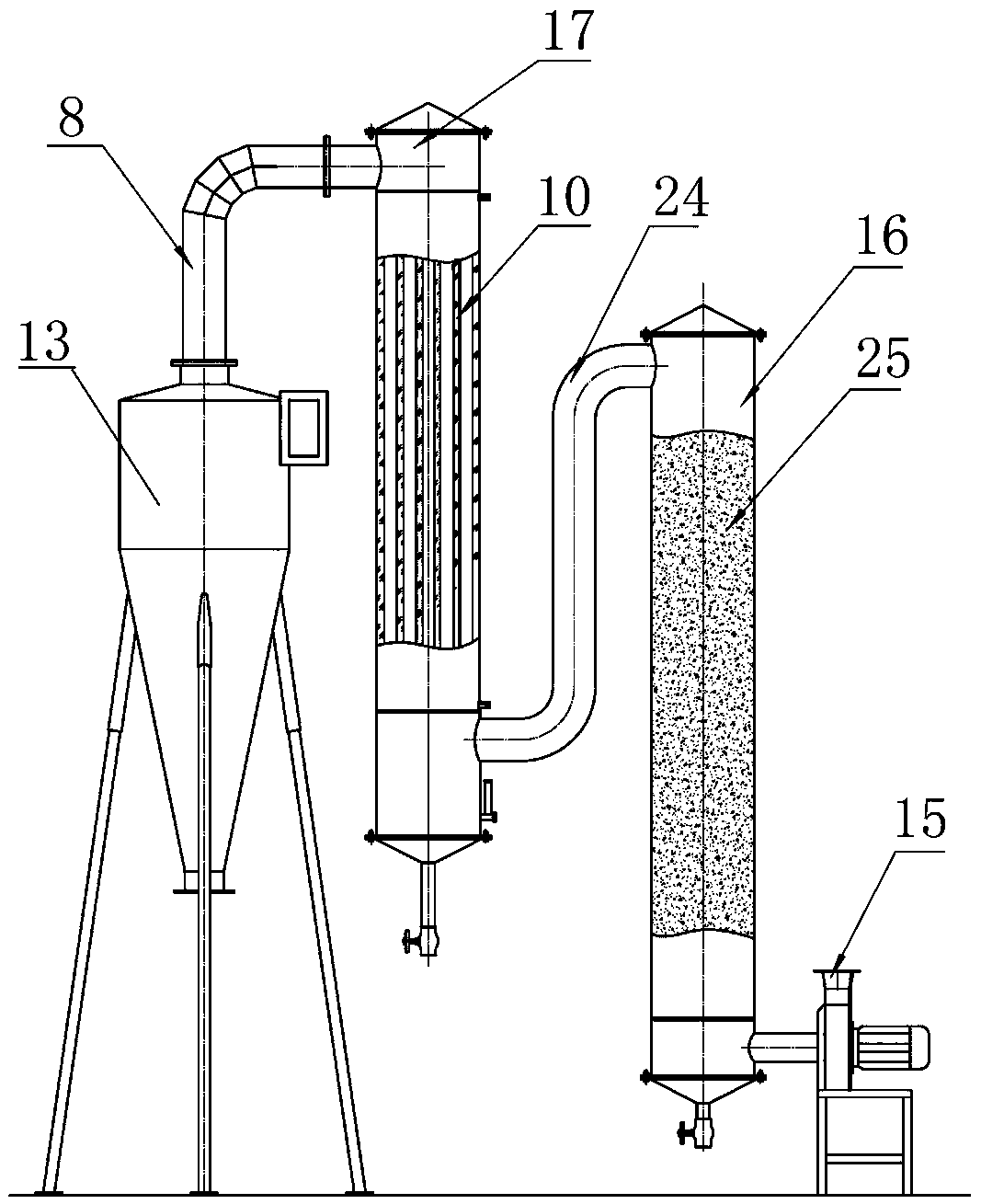

[0020] Such as Figure 1-3 Shown is a biomass dry distillation cracking furnace with the structure of the present invention, which is used to process biomass raw materials such as straws, branches, etc., which includes a feeding unit, a carbonization unit, and a separation and recovery unit;

[0021] The feeding unit includes a screw feeder 19, the lower end of the screw feeder is matched with the lower end of the raw material feed hopper 23, and the upper end of the screw feeder is matched with the feed hopper of the carbonization unit;

[0022] The carbonization unit includes a feed port 2, a carbonizer, a cooler 3, and a discharge port 22 that are connected in sequence; the carbonizer and the cooler are all straight pipes, and are arranged horizontally inside the casing 1, in the straight pipe A raw material conveying propeller 12 is arranged inside; the raw material conveying propeller is a screw propeller, which includes a rotating shaft with spiral fins. One end of the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com