PVC plastic with self-antibacterial property and preparation method thereof

A performance and plastic technology, applied in the field of PVC plastic with self-antibacterial properties and its preparation, can solve the problems of biological safety doubts, harmfulness, poor dispersion and poor stability and durability, and achieve shortened processing cycle, wide sterilization range, and reduced The effect of melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

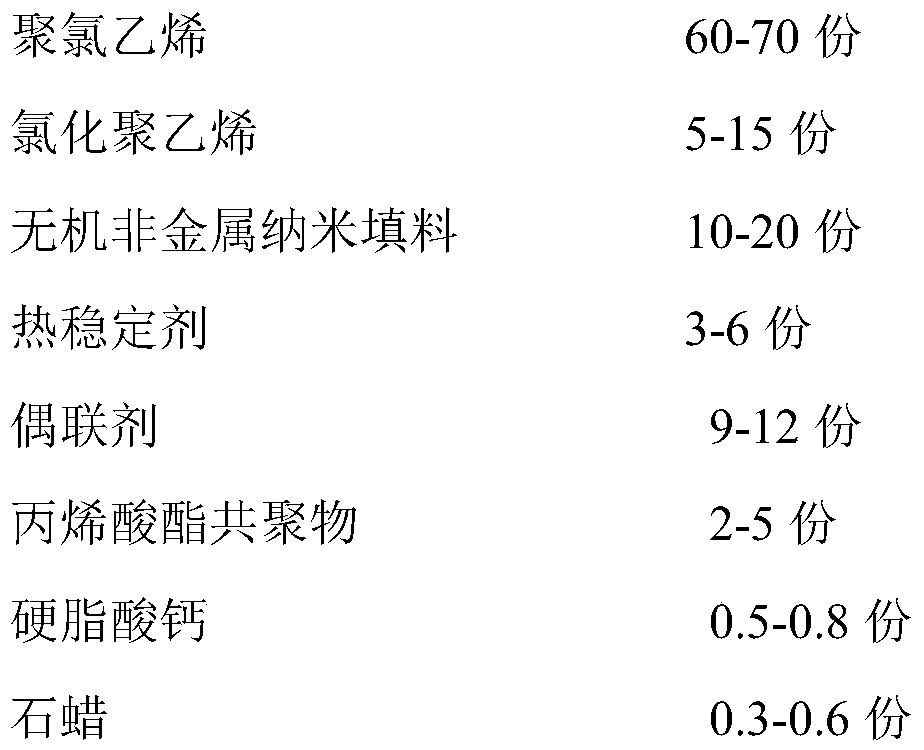

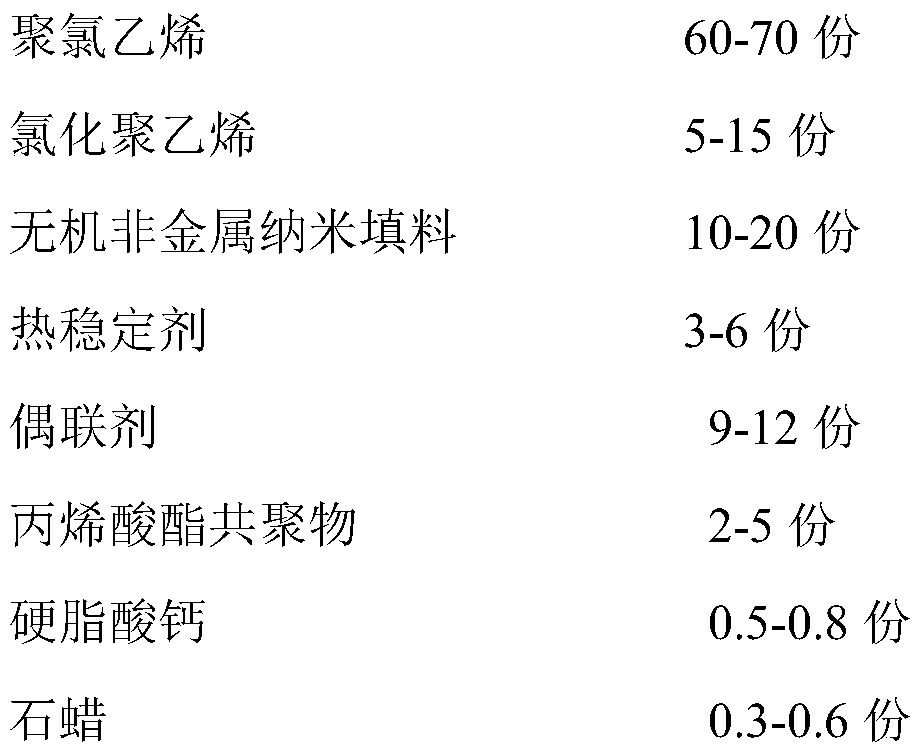

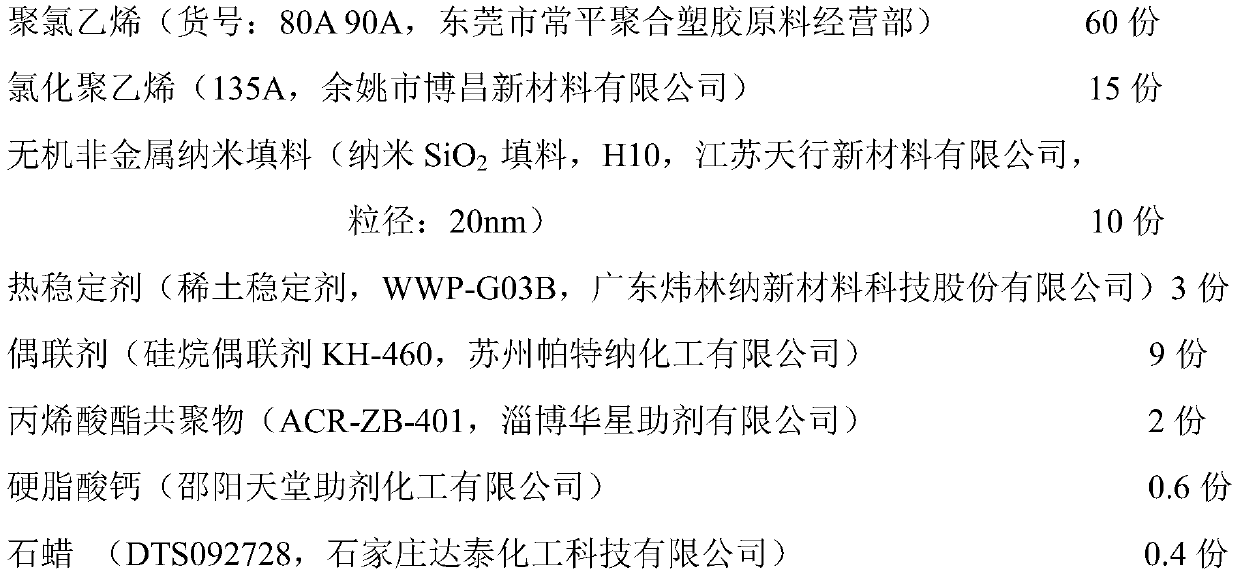

[0047] In parts by mass, the raw material formula of the PVC plastic sheet with self-antibacterial properties is as follows:

[0048]

[0049] During preparation, polyvinyl chloride, chlorinated polyethylene, nano-SiO 2 Filler, heat stabilizer, silane coupling agent, acrylate copolymer, calcium stearate, and paraffin are weighed according to the mass ratio of the formula. First, the silane coupling agent KH-460 was used for nano-SiO 2 The surface modification of the filler is carried out by first using deionized water to modify the nano-SiO 2 The filler is made into a slurry with a mass fraction of 10% and added to a three-necked flask using a magnetic stirring water bath (DF-101S, Shenzhen Dingxinyi Experimental Equipment Co., Ltd.) to heat up to 75 ° C. After stirring evenly, according to the above ratio A corresponding amount of silane coupling agent KH-460 was added, reacted at 75°C for 2 hours, and then the reacted slurry was filtered, dried, pulverized and sieved to...

Embodiment 2

[0052] The difference from Example 1 is that nano-CaCO is used in the raw material formula of this example. 3 As inorganic non-metallic nanofillers, other types of coupling agents, stabilizers, acrylate copolymers and different ratios, as well as other processing and molding methods are selected.

[0053] In parts by mass, the raw material formula of the PVC plastic sheet with self-antibacterial properties is as follows:

[0054]

[0055] During preparation, polyvinyl chloride, chlorinated polyethylene, nano-CaCO 3 Filler, heat stabilizer, aluminate coupling agent, acrylate copolymer, calcium stearate, and paraffin are weighed according to the mass ratio shown in the formula.

[0056] First, a coupling agent was used to synthesize nano-CaCO 3 The filler is surface modified, specifically, nano-CaCO2 is treated with deionized water. 3 The filler is made into a slurry with a mass fraction of 15% and added to a three-necked flask using a magnetic stirring water bath (DF-101S...

Embodiment 3

[0060] The difference from Example 1 is that nano-TiO is used in the raw material formula of this example. 2 As inorganic non-metallic nanofillers, other types of coupling agents, stabilizers, acrylate copolymers and different ratios were selected.

[0061] In parts by mass, the raw material formula of the PVC plastic sheet with self-antibacterial properties is as follows:

[0062]

[0063]

[0064] During preparation, polyvinyl chloride, chlorinated polyethylene, nano-TiO 2 Filler, heat stabilizer, titanate coupling agent TM-200S, acrylate copolymer (stone-plastic ACR), calcium stearate, and paraffin are weighed according to the mass ratio shown in the formula.

[0065] First, the coupling agent was used to 2 Surface modification of fillers, specifically using deionized water to transform nano-TiO 2 The DK405 filler is made into a slurry with a mass fraction of 20%, and is added to a three-necked flask using a magnetic stirring water bath (DF-101S, Shenzhen Dingxinyi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com