Polyester waste silk recycling and purifying device and recycling process thereof

A polyester waste yarn and purification device technology, applied in the field of polyester waste yarn recycling, can solve the problems of large vibration of the cutting machine, uneven washing treatment of polyester waste yarn, complicated process, etc., achieve low equipment requirements, facilitate popularization and use, and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] A process for recycling and purifying polyester waste silk, comprising the following steps:

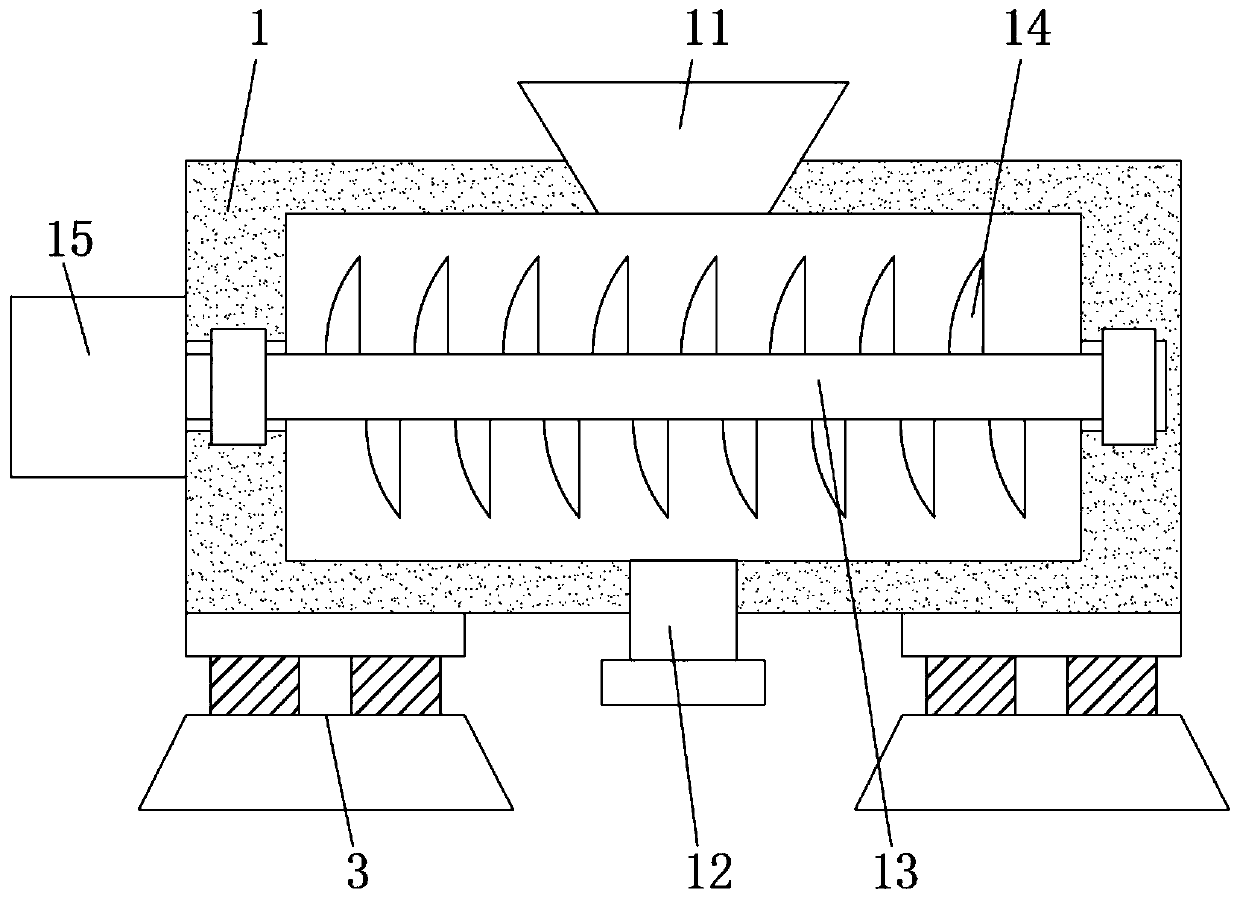

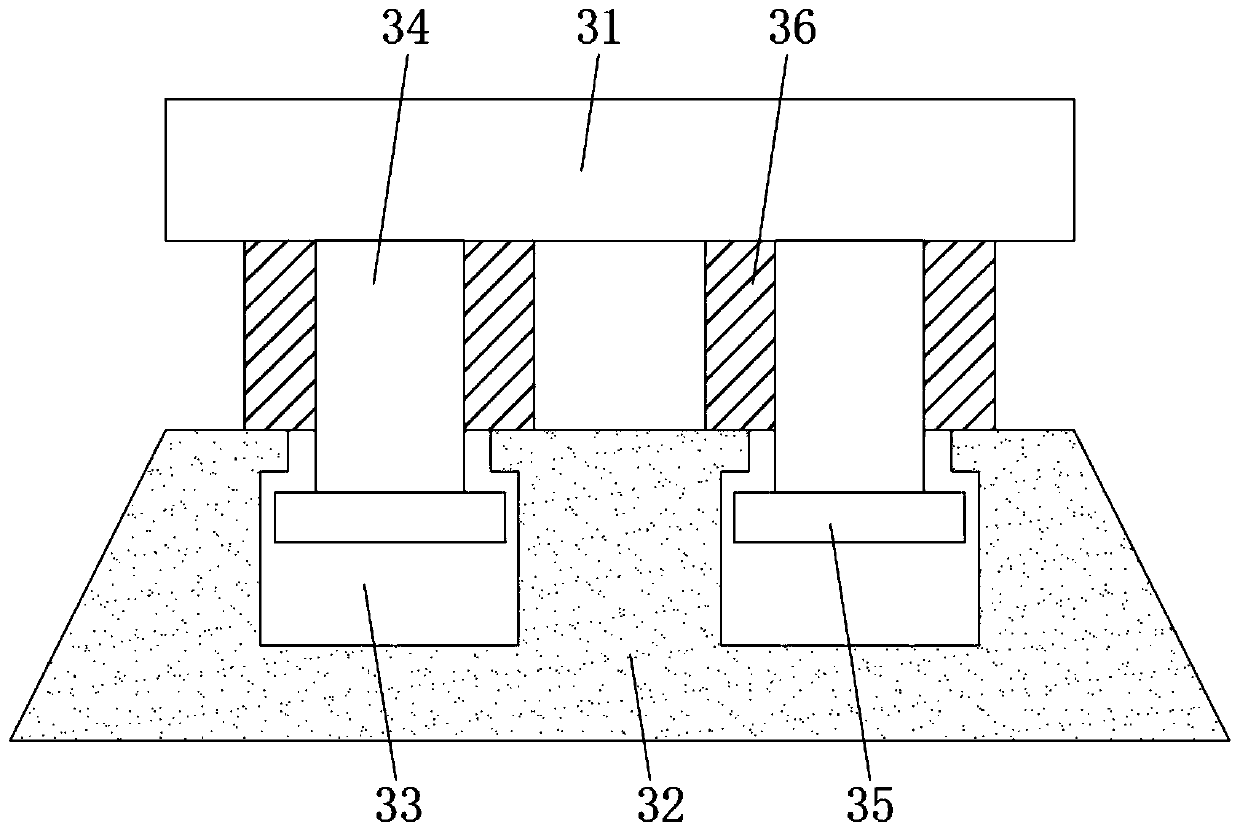

[0065] A: Cutting: first put a certain amount of polyester waste yarn into the cutting chamber 1 through the feeding funnel 11, then start the first servo motor 15, the first servo motor 15 rotates by driving the cutting shaft 13, and the cutting shaft 13 drives the cutting knife 14 Carry out cutting treatment to polyester waste silk, cutting time is 5min;

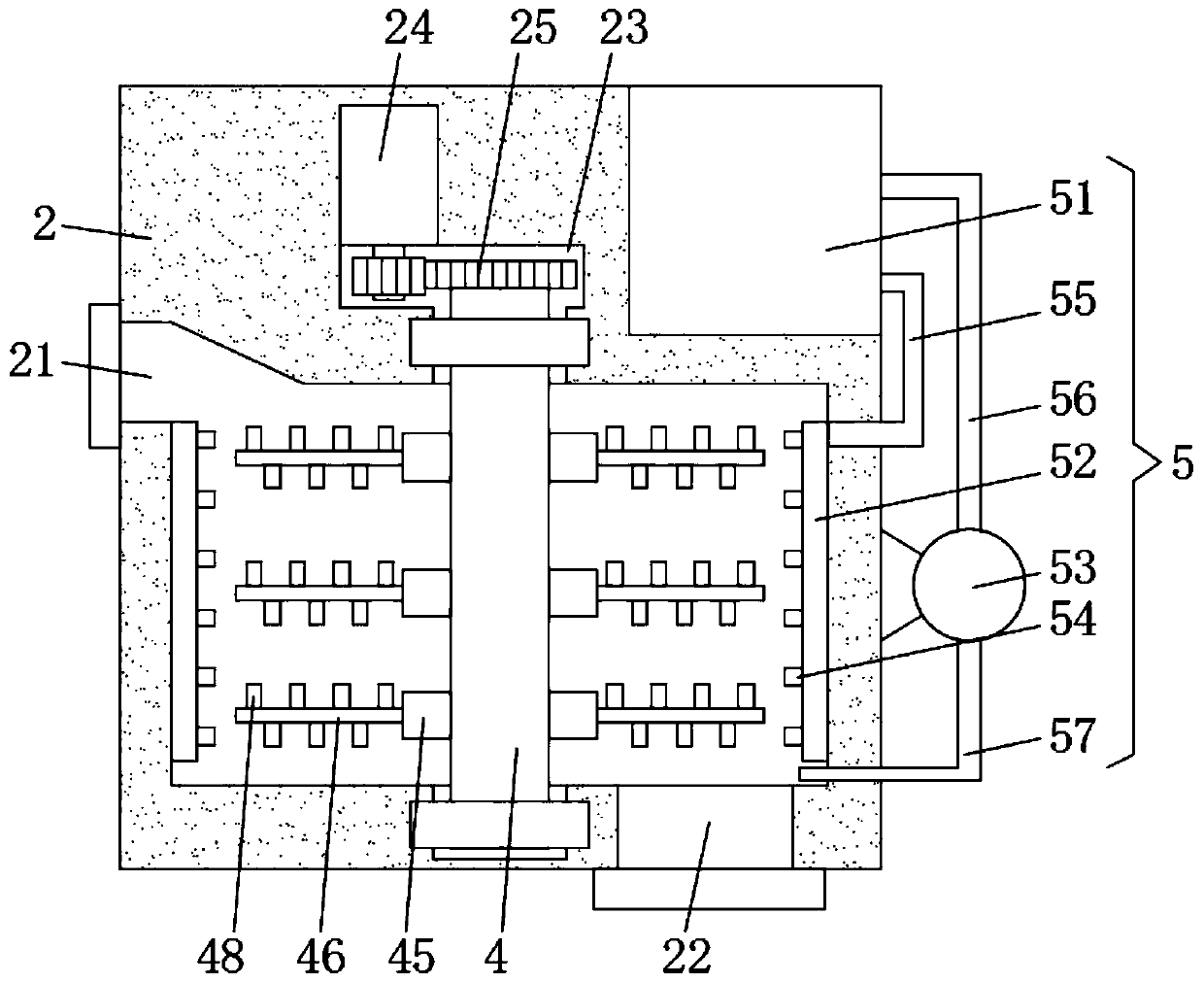

[0066] B: Water washing: After the cutting operation is finished, stop the first servo motor 15, then take out the polyester from the discharge pipe 12, put the pulverized polyester into the washing chamber 2 through the feeding port 21, and then close the feeding port 21, After opening the water tank 51, water is delivered to the water storage ring 52 through the water tank 51, and the water is finally ejected from the high-pressure nozzle 54 to achieve the effect of cleaning;

[0067] C: Water cycle: turn on the circulat...

Embodiment 2

[0073] A: Cutting: first put a certain amount of polyester waste yarn into the cutting chamber 1 through the feeding funnel 11, then start the first servo motor 15, the first servo motor 15 rotates by driving the cutting shaft 13, and the cutting shaft 13 drives the cutting knife 14 Carry out cutting treatment to polyester waste silk, cutting time is 10min;

[0074] B: Water washing: After the cutting operation is finished, stop the first servo motor 15, then take out the polyester from the discharge pipe 12, put the pulverized polyester into the washing chamber 2 through the feeding port 21, and then close the feeding port 21, After opening the water tank 51, water is delivered to the water storage ring 52 through the water tank 51, and the water is finally ejected from the high-pressure nozzle 54 to achieve the effect of cleaning;

[0075] C: Water cycle: turn on the circulating water pump 53, and the circulating water pump 53 extracts the water resources inside the washing ...

Embodiment 3

[0081] A: Cutting: first put a certain amount of polyester waste yarn into the cutting chamber 1 through the feeding funnel 11, then start the first servo motor 15, the first servo motor 15 rotates by driving the cutting shaft 13, and the cutting shaft 13 drives the cutting knife 14 Carry out cutting treatment to polyester waste silk, cutting time is 15min;

[0082]B: Water washing: After the cutting operation is finished, stop the first servo motor 15, then take out the polyester from the discharge pipe 12, put the pulverized polyester into the washing chamber 2 through the feeding port 21, and then close the feeding port 21, After opening the water tank 51, water is delivered to the water storage ring 52 through the water tank 51, and the water is finally ejected from the high-pressure nozzle 54 to achieve the effect of cleaning;

[0083] C: Water cycle: turn on the circulating water pump 53, and the circulating water pump 53 extracts the water resources inside the washing c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com