Eccentric translation type polishing grinding head and polisher containing grinding head

A translational and polishing grinding technology, which is applied in the direction of surface polishing machine tools, grinding heads, grinding/polishing equipment, etc., can solve the problems that affect the swing accuracy of the grinding head, the difficulty of controlling the gap, and the complex structure of the grinding head. Achieve the effect of increasing the swing range and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

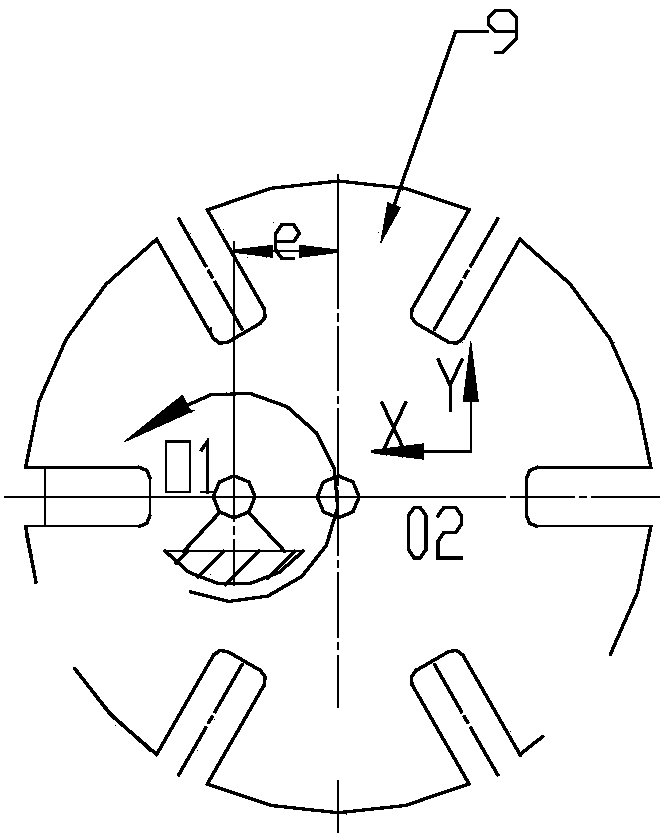

[0035] Such as image 3 with 4 As shown, an eccentric translational polishing grinding head includes an eccentric wheel 8, a dial 9 and a pendulum mechanism 10, the eccentric wheel 8 is connected to the dial 9, and the geometric center O of the eccentric wheel 8 2 Coincident with the geometric center of the dial 9, the rotation center O of the eccentric wheel 8 1 Located at the geometric center O of the eccentric wheel 8 2 One side, the rotation center O of the eccentric wheel 8 1 and the geometric center O 2 An eccentricity is formed between them, several radial grooves 91 are arranged on the dial 9 along the circumferential direction of the dial 9, and a single radial groove 91 is arranged along the radial direction of the dial 9, the One end of the swing rod mechanism 10 is provided with a swing rod ball head, which is inserted into the radial groove 91, and the swing rod ball head slides in the radial direction of the radial groove 91, and the swing rod ball The diame...

Embodiment 2

[0044] This embodiment only describes the difference from the above embodiment, and other technical features are the same as the above embodiment. Both ends of the radial groove 91 are closed ends, which prevent the ball head of the swing rod from slipping out along the radial direction of the radial groove 91 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com