Exhaust bearing block and screw compressor

A technology of bearing seat and air supply port, which is applied in the field of compressors, can solve the problems of noise and vibration of the air supply pipeline, large vibration and noise of the air supply pipeline, and solve the problems of large noise and vibration, reduce the pulsation of the air supply airflow, reduce vibration and noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

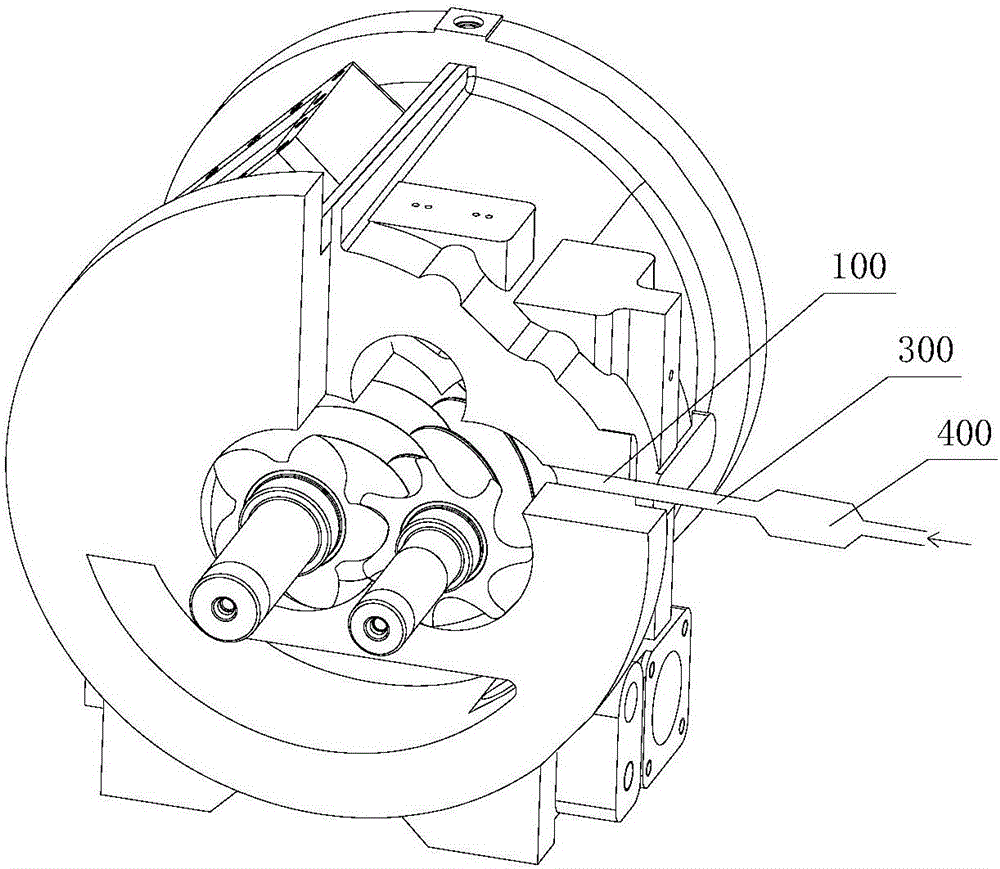

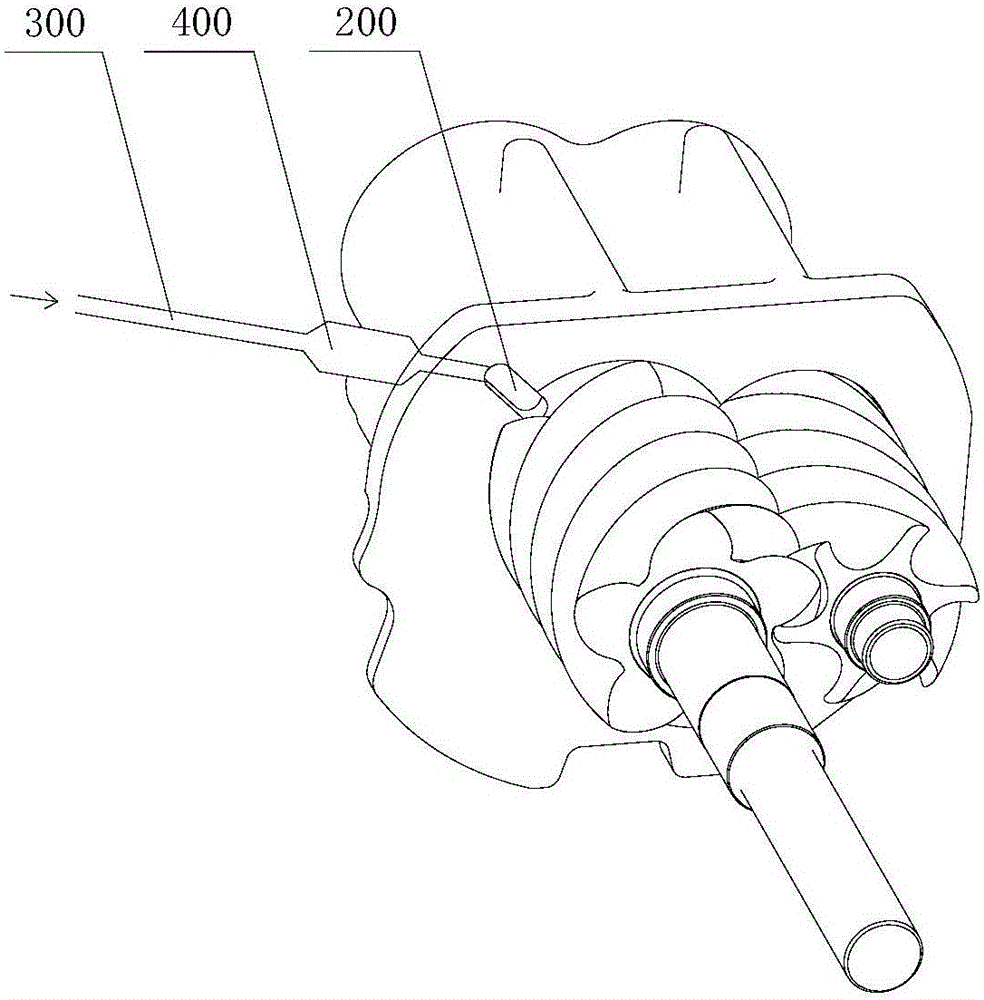

[0030] This embodiment provides an exhaust bearing seat, such as Figure 3-7 As shown, the exhaust bearing seat includes a bearing seat body 1, an air supply port 2 opened on the end surface of the bearing seat body 1, and an air supply pulsation attenuation chamber 3 arranged on the bearing seat body 1 and connected to the air supply port 2, The volume of the air supply pulsation attenuation cavity 3 is larger than the volume of the air supply port 2 . Through the above-mentioned air supply pulsation attenuation chamber 3, during the periodic air supply process of the air supply port 2, the airflow pulsation generated by the air supply port 2 will attenuate in the air supply pulsation attenuation chamber 3, the specific principle is: first enter the air supply pulsation attenuation chamber 3 The pulsation frequency of the airflow inside will change, which is different from the pulsation frequency of the airflow that enters the air supply pulsation attenuation chamber 3 later,...

Embodiment 2

[0041] This embodiment provides a screw compressor, which includes the discharge bearing housing described in Embodiment 1. By arranging the above-mentioned exhaust bearing seat, the problem of large noise and vibration of the air supply pipeline of the existing screw compressor is effectively solved, and the reliability of the screw compressor is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com