A kind of preparation method of high transmittance buffer layer structure for transparent electrode of laminated battery

A transparent electrode, high transmittance technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problems of poor light transmittance of thin-layer metal, complicated preparation of silver nanowires, poor repeatability, etc., and achieves many and simple deposition methods. , Protect the transparent organic interface layer, a variety of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

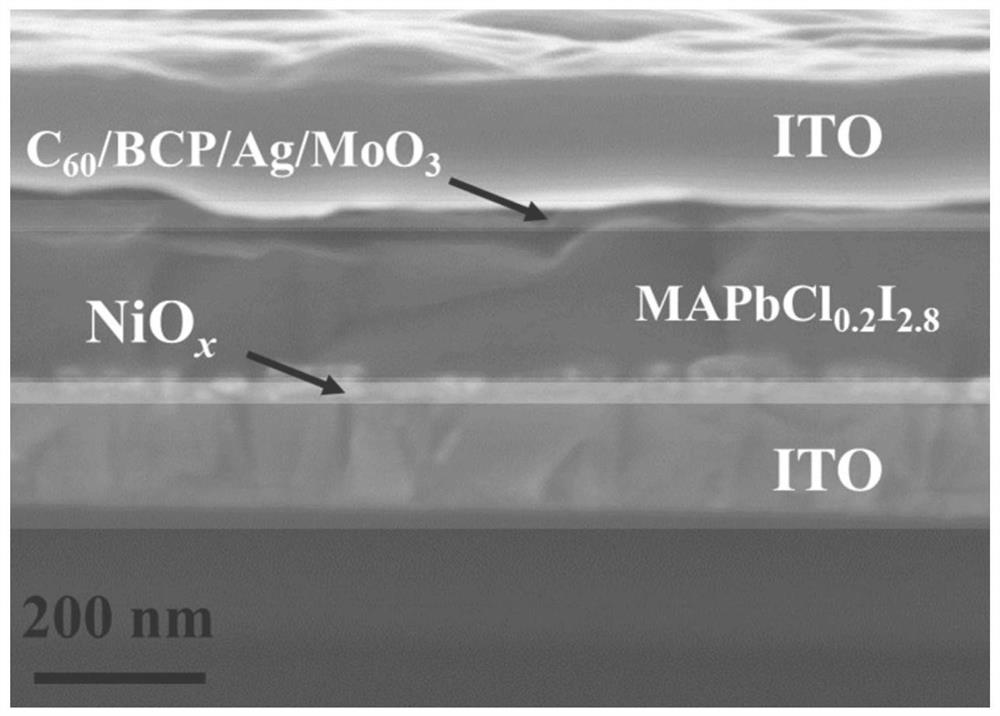

[0029] Ag is generated by in situ chemical reaction 2 MoO 4 Preparation of perovskite transparent cells as a buffer layer.

[0030] (1) The commercially purchased indium tin oxide (ITO) glass was first cleaned with detergent, and then ultrasonically cleaned with tap water, deionized water, ethanol, acetone, and isopropanol in sequence.

[0031] (2) After drying the ITO, spin-coat a 30 nm-thick hole transport layer NiO for use.

[0032] (3) Preparation of 250 nm thick CH on the NiO layer 3 NH 3 PbCl 0.2 I 2.8 perovskite layer.

[0033] (4) In vacuum (-4 Pa) Evaporation at 40 nm C 60 as the electron transport layer, after C 60 10 nm BCP was evaporated on top as a barrier layer.

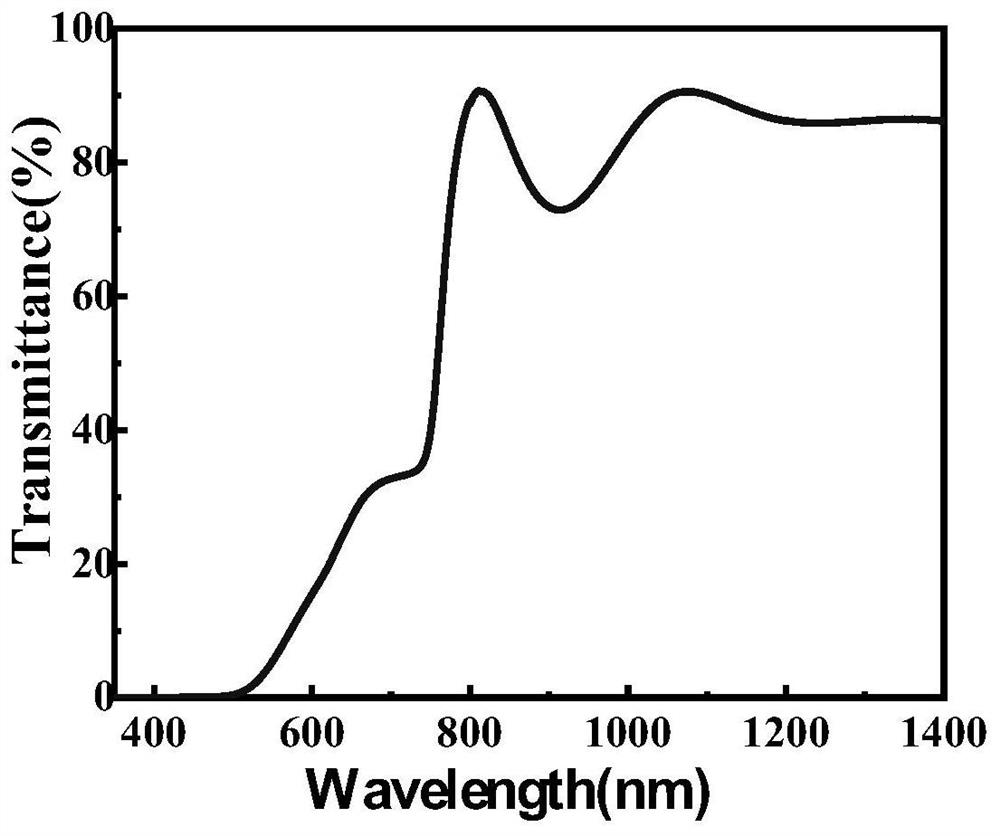

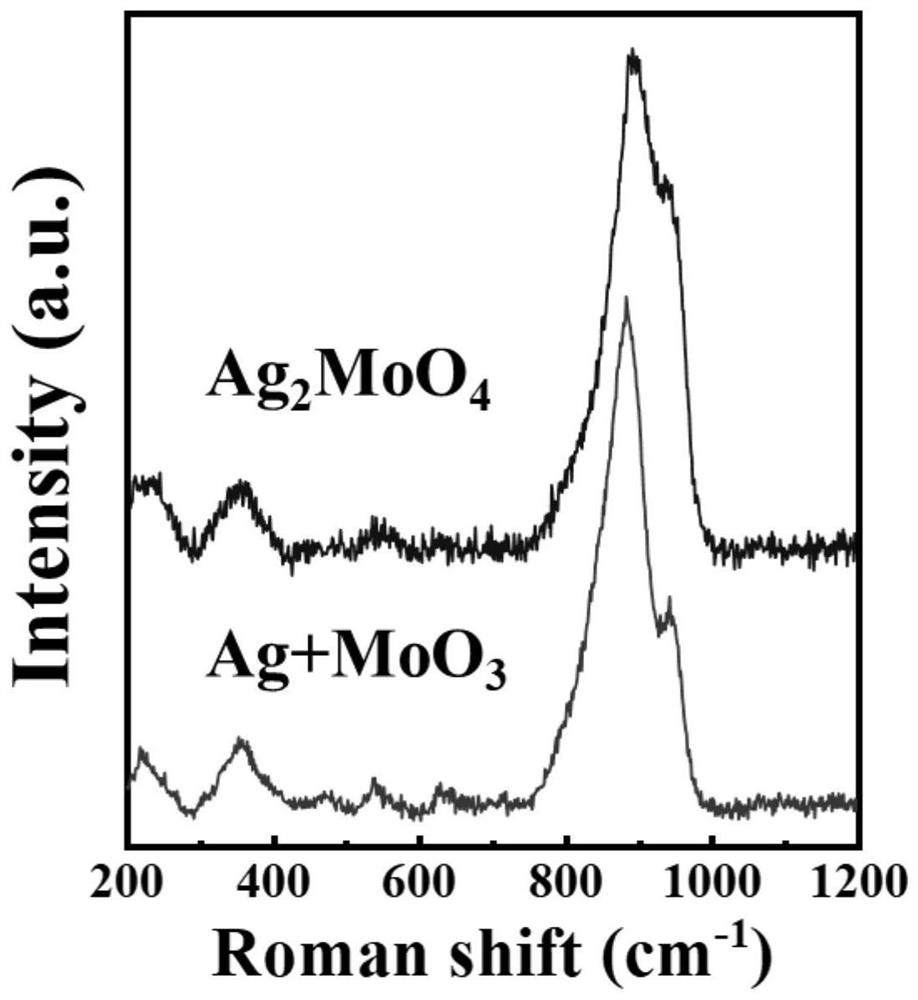

[0034] (5) On BCP, in vacuum (-4 In the Pa) environment, 1 nm Ag was first evaporated, and the evaporation current was 35A. Then 3 nm MoO was evaporated on Ag 3 , the evaporation temperature is 450~550℃, and the current is 1.8~2.6A. in high vacuum (-4 Pa) and high temperature (>100 °C), Ag a...

Embodiment 2

[0039] Ag is generated by in situ chemical reaction 2 MoO 4 Preparation of perovskite transparent cells as a buffer layer.

[0040] (1) The commercially purchased indium tin oxide (ITO) glass was first cleaned with detergent, and then ultrasonically cleaned with tap water, deionized water, ethanol, acetone, and isopropanol in sequence.

[0041] (2) After drying the ITO, spin-coat a 30 nm-thick hole transport layer NiO for use.

[0042] (3) Preparation of 250 nm thick CH on the NiO layer 3 NH 3 PbCl 0.2 I 2.8 perovskite layer.

[0043] (4) In vacuum (-4 Pa) Evaporation at 40 nm C 60 as the electron transport layer, after C 60 10 nm BCP was evaporated on top as a barrier layer.

[0044] (5) On BCP, in vacuum (-4 In the Pa) environment, 3 nm Ag was first evaporated, and the evaporation current was 40A. Then 1 nm MoO was evaporated on Ag 3 , the evaporation temperature is 450 ℃, and the current is 2A. in high vacuum (-4 Pa) and high temperature (>100℃), Ag atoms deposi...

Embodiment 3

[0048] Ag is generated by in situ chemical reaction 2 MoO 4 Preparation of perovskite transparent cells as a buffer layer.

[0049] (1) The commercially purchased indium tin oxide (ITO) glass was first cleaned with detergent, and then ultrasonically cleaned with tap water, deionized water, ethanol, acetone, and isopropanol in sequence.

[0050] (2) After drying the ITO, spin-coat a 30 nm-thick hole transport layer NiO for use.

[0051] (3) Preparation of 250 nm thick CH on the NiO layer 3 NH 3 PbCl 0.2 I 2.8 perovskite layer.

[0052] (4) In vacuum (-4 Pa) Evaporation at 40 nm C 60 as the electron transport layer, after C 60 10 nm BCP was evaporated on top as a barrier layer.

[0053] (5) On BCP, in vacuum (-4 In the Pa) environment, 5 nm Ag was first evaporated, and the evaporation current was 45 A. Then 20nm MoO was evaporated on Ag 3 , the evaporation temperature is 450~600 ℃, and the current is 2~3 A. in high vacuum (-4 Pa) and high temperature (>100 °C), Ag at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com