A hard fiber aging system and pulping method thereof

A curing and fiber technology, applied in the hard fiber curing system and its pulping field, can solve the problems of high pulping cost, environmental health impact, etc., and achieve the effects of softening raw materials, reducing the use of liquid medicine, and prolonging the curing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

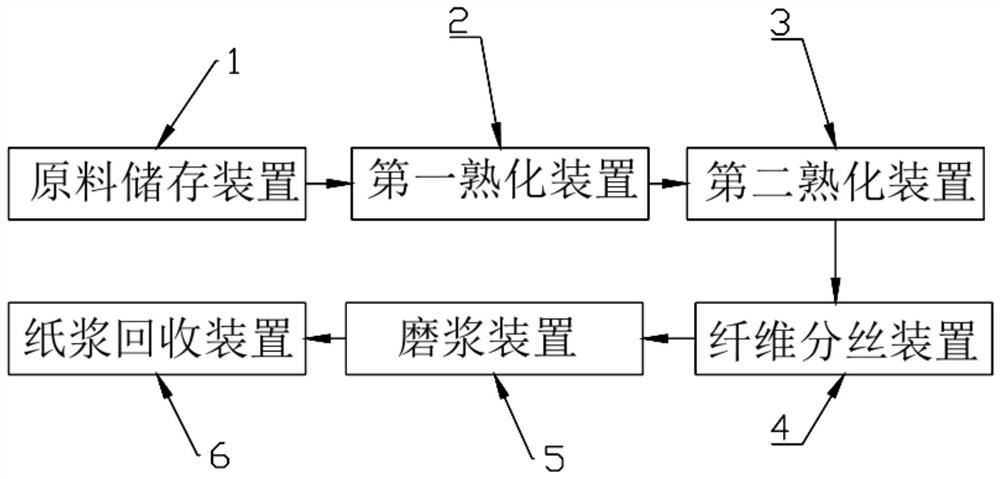

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

[0029] like figure 1 The hard fiber aging treatment system of the present invention includes a raw material storage device 1, a first curing device 2, a fiber separating device 4, a refining device 5 and a pulp recovery device 6 arranged in sequence, and also includes a second curing device 3 , the second curing device 3 is arranged between the first curing device 2 and the fiber splitting device 4, the first curing device 2 is set as a square structure with an accommodating cavity inside, and the cross-sectional shape of the first curing device 2 is The right-angled trapezoid with a wide top and a narrow bottom can facilitate better curing of the raw materials by setting two curing devices, thereby better softening the raw materials and facilitating subsequent fiber separation. At the same time, by setting two curing devices, the curing Time, reduce the use of liquid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com