Beating enzyme preparation and its preparation method and application

A technology for pulping enzymes and preparations, applied in the field of papermaking, can solve the problems of reduced profit margins of paper products, difficulties in the survival of papermaking enterprises, and reduced strength of papermaking, so as to improve the utilization rate, reduce the power consumption of refining, and promote cutting and swelling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

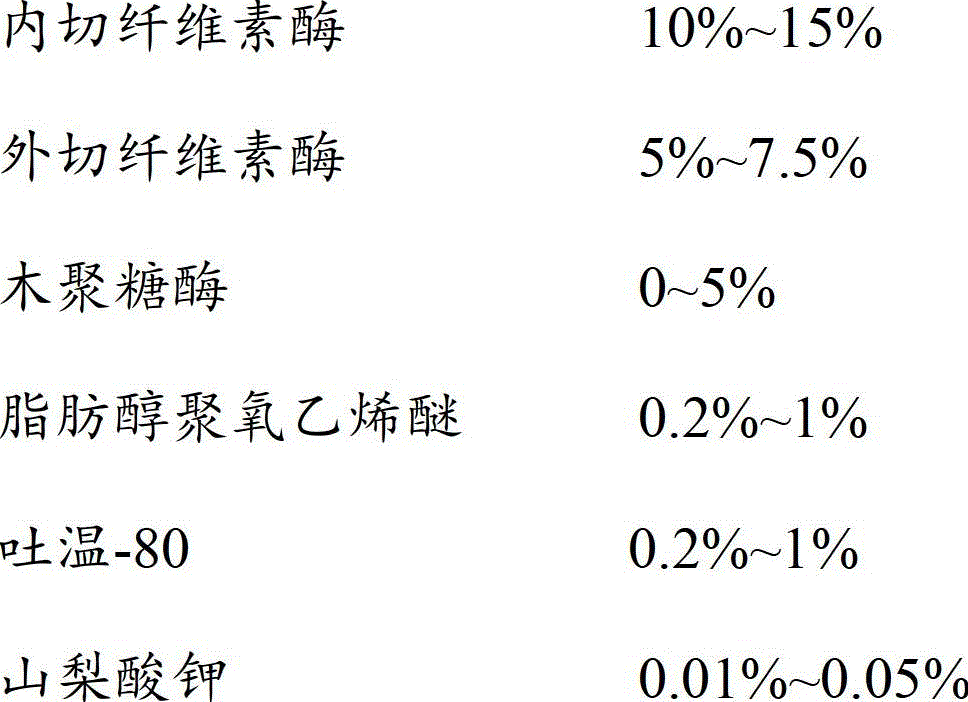

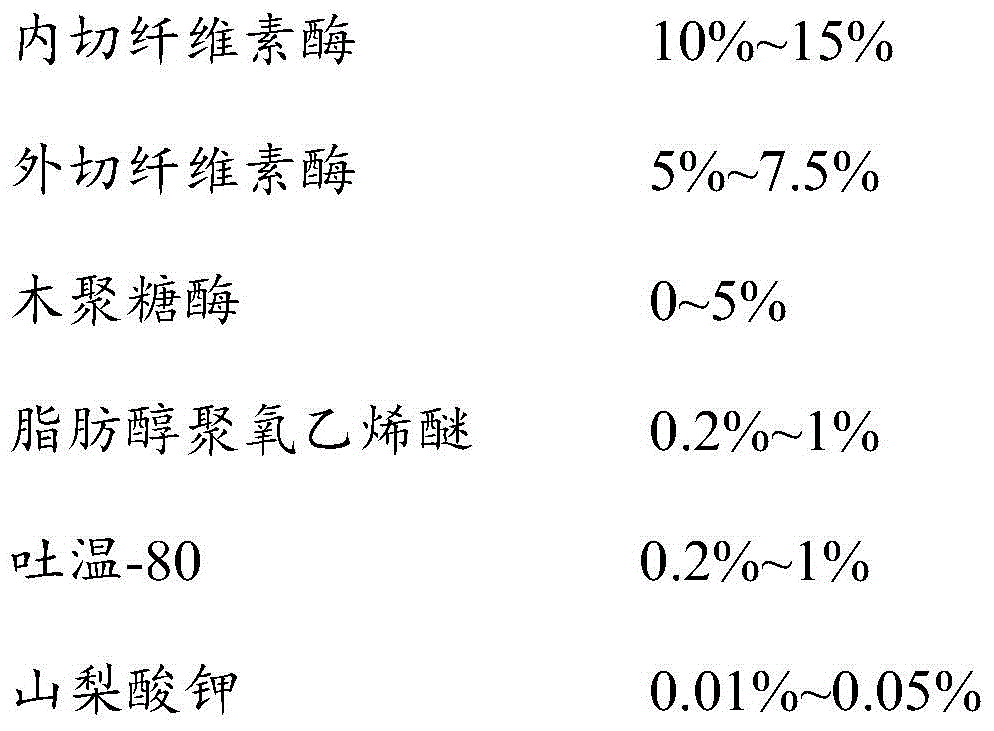

[0028] (1) Beating enzyme preparation formula: by weight percentage, 12% endo-cellulase, 7.5% exo-cellulase, 0.6% fatty alcohol polyoxyethylene (20) ether, 0.4% Tween- 80. Potassium sorbate of 0.01%, the balance is deionized water; weigh each component according to the above formula;

[0029] (2) First dissolve potassium sorbate with a small amount of deionized water, then dissolve and dilute Tween-80 and fatty alcohol polyoxyethylene (20) ether in a mixing tank with a sufficient amount of deionized water, and then pour the dissolved sorbic acid Potassium acid;

[0030] (3) Add endo-cellulase and exo-cellulase, and stir at 40 rpm for 30 minutes to obtain the beating enzyme preparation.

[0031] The enzyme activity of the endo-cellulase in the prepared beating enzyme preparation was 1200 U / mL, and the enzyme activity of the exo-cellulase was 300 U / mL.

Embodiment 2

[0033] (1) Beating enzyme formulation: by weight percentage, 15% endo-cellulase, 5% exo-cellulase, 1% xylanase, 0.2% fatty alcohol polyoxyethylene (20) Ether, 1% Tween-80, 0.03% potassium sorbate, and the balance being deionized water; each component is weighed according to the above formula;

[0034] (2) First dissolve potassium sorbate with a small amount of deionized water, then dissolve and dilute Tween-80 and fatty alcohol polyoxyethylene (20) ether in a mixing tank with a sufficient amount of deionized water, and then pour the dissolved sorbic acid Potassium acid;

[0035] (3) Add endo-cellulase, exo-cellulase and xylanase, and stir at a speed of 40 rpm for 30 minutes to obtain the beating enzyme preparation.

[0036] The enzyme activity of endo-cellulase in the prepared beating enzyme preparation was 1500 U / mL, the enzyme activity of exo-cellulase was 200 U / mL, and the enzyme activity of xylanase was 100 U / mL.

Embodiment 3

[0038] (1) Beating enzyme preparation formula: by weight percentage, 10% endo-cellulase, 6% exo-cellulase, 3% xylanase, 0.4% fatty alcohol polyoxyethylene (20) Ether, 0.6% Tween-80, 0.05% potassium sorbate, the balance is deionized water; each component is weighed according to the above formula;

[0039] (2) First dissolve potassium sorbate with a small amount of deionized water, then dissolve and dilute Tween-80 and fatty alcohol polyoxyethylene (20) ether in a mixing tank with a sufficient amount of deionized water, and then pour the dissolved sorbic acid Potassium acid;

[0040] (3) Add endo-cellulase, exo-cellulase and xylanase, and stir at a speed of 40 rpm for 30 minutes to obtain the beating enzyme preparation.

[0041] The enzyme activity of endo-cellulase in the prepared beating enzyme preparation was 1000 U / mL, the enzyme activity of exo-cellulase was 240 U / mL, and the enzyme activity of xylanase was 300 U / mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com