Application of a thermophilic chaetomium cellulase in pulp and papermaking process

A thermophilic Chaetomium and cellulase technology, which is applied in textiles and papermaking, fiber raw material treatment, enzymes, etc., can solve the problems of acid cellulase inactivation, low interlayer bonding strength, and poor fiber bonding force. Achieve the effects of reducing the content of fine fibers, no obvious changes in bulk and stiffness, and improving the bond strength and tensile strength between the paper layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1 Preparation of Chaetomium thermophila cellulase expressed by Trichoderma reesei (see Example 1 of the specification of the invention patent application publication CN103343111A with the patent application number 201310280267.6).

Embodiment 2

[0037] Example 2 Preparation of Chaetomium thermophila cellulase expressed by Pichia pastoris (see Example 3 of the specification of the invention patent application publication CN103343111A with the patent application number 201310280267.6).

Embodiment 3

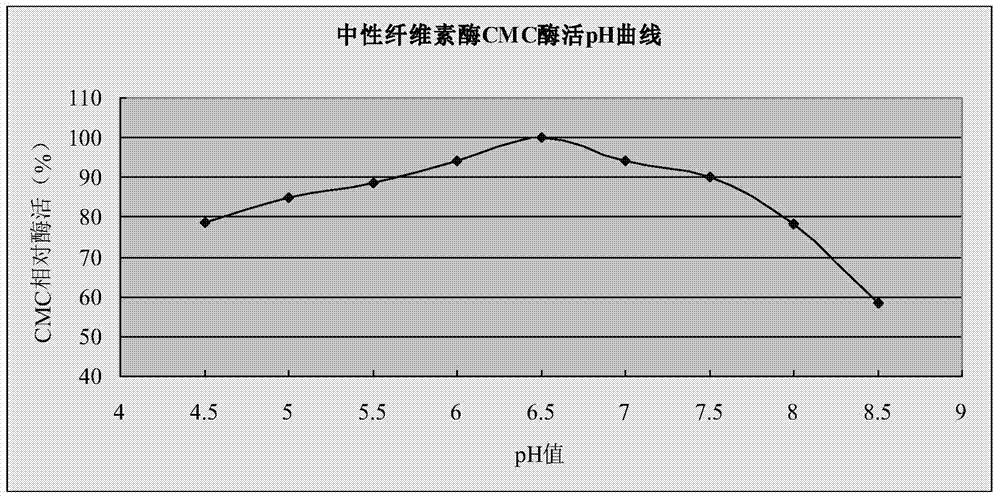

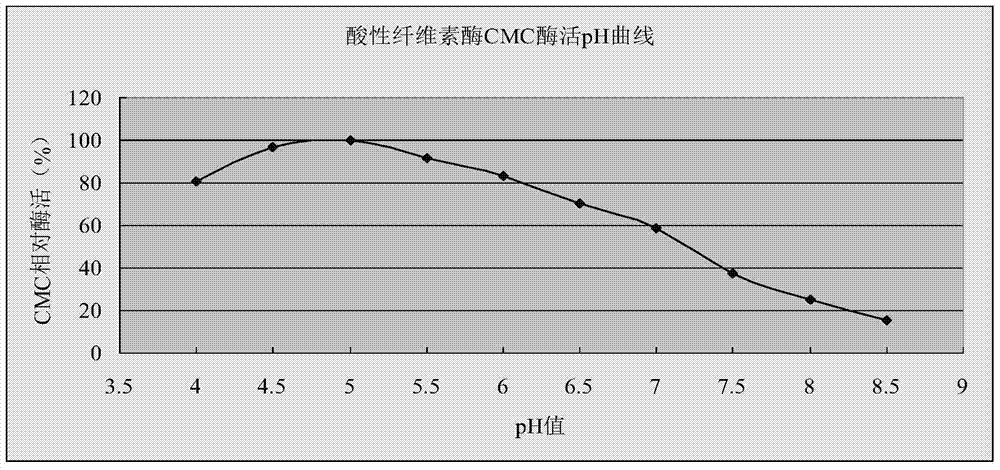

[0038] Example 3 Qualitative test of Chaetomium thermophila cellulase as neutral cellulase in papermaking process (enzyme activity survival rate is above 90%, and enzyme activity is less affected by pH in the neutral range)

[0039] The specific steps and methods of cellulase CMC enzyme activity test are as follows:

[0040] 1. Principle

[0041] Cellulase hydrolyzes cellulose to produce monosaccharides and oligosaccharides under certain temperature and pH conditions. Oligosaccharides with reducing ends and monosaccharides with reducing groups undergo a color reaction with DNS reagent under boiling water bath conditions. The intensity of the color of the reaction solution is proportional to the amount of reducing sugar produced by enzymatic hydrolysis. The amount of reducing sugar produced is related to the reaction. The cellulase activity in the solution is proportional to the absorbance of the reaction solution by spectrocolorimetry, and the cellulase activity can be calculat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com