Micro-nano three-dimensional printing method and device based on laser chemical vapor deposition

A chemical vapor deposition, three-dimensional printing technology, applied in gaseous chemical plating, metal material coating process, coating and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

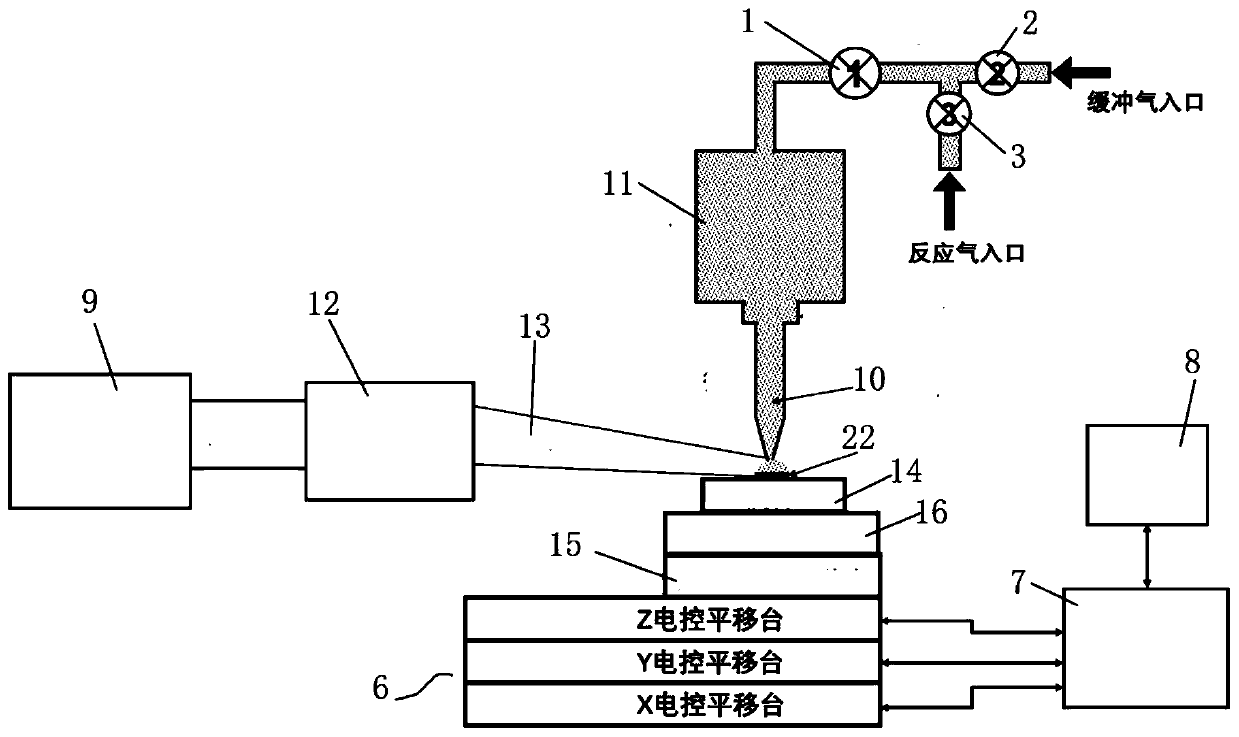

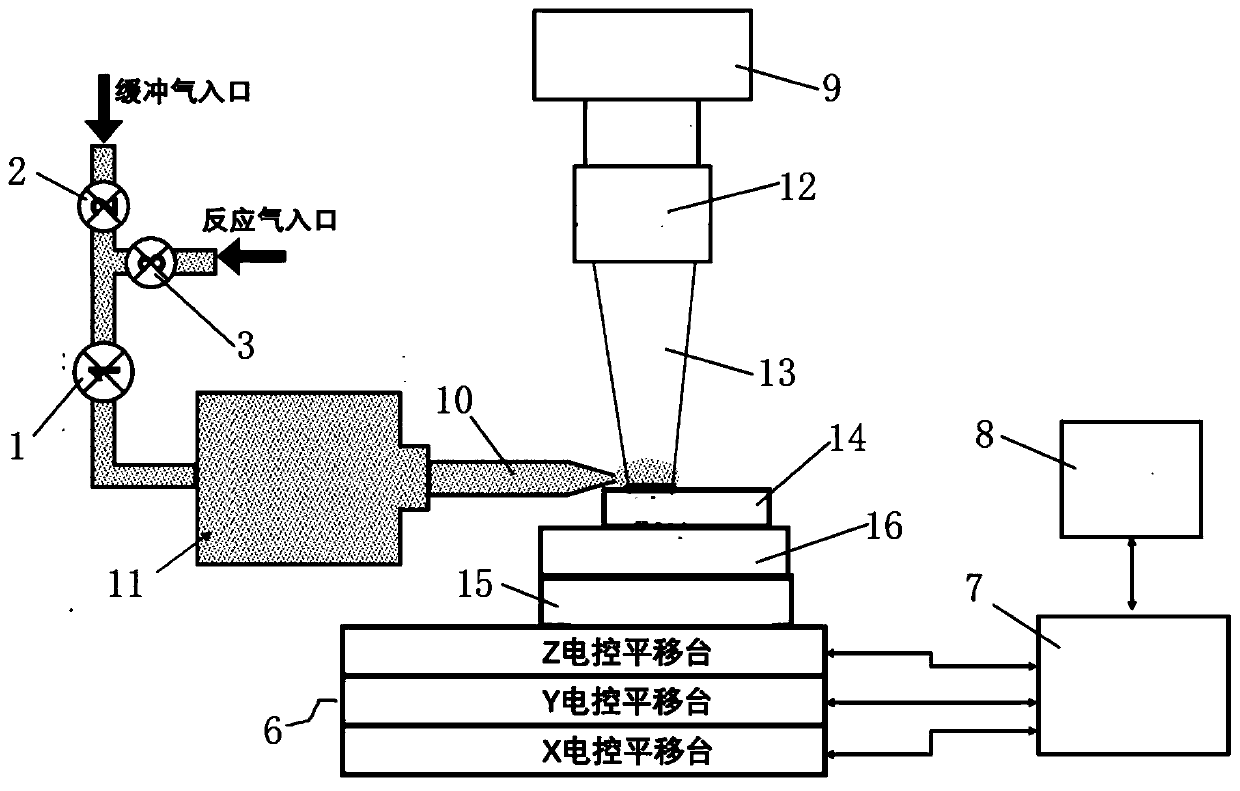

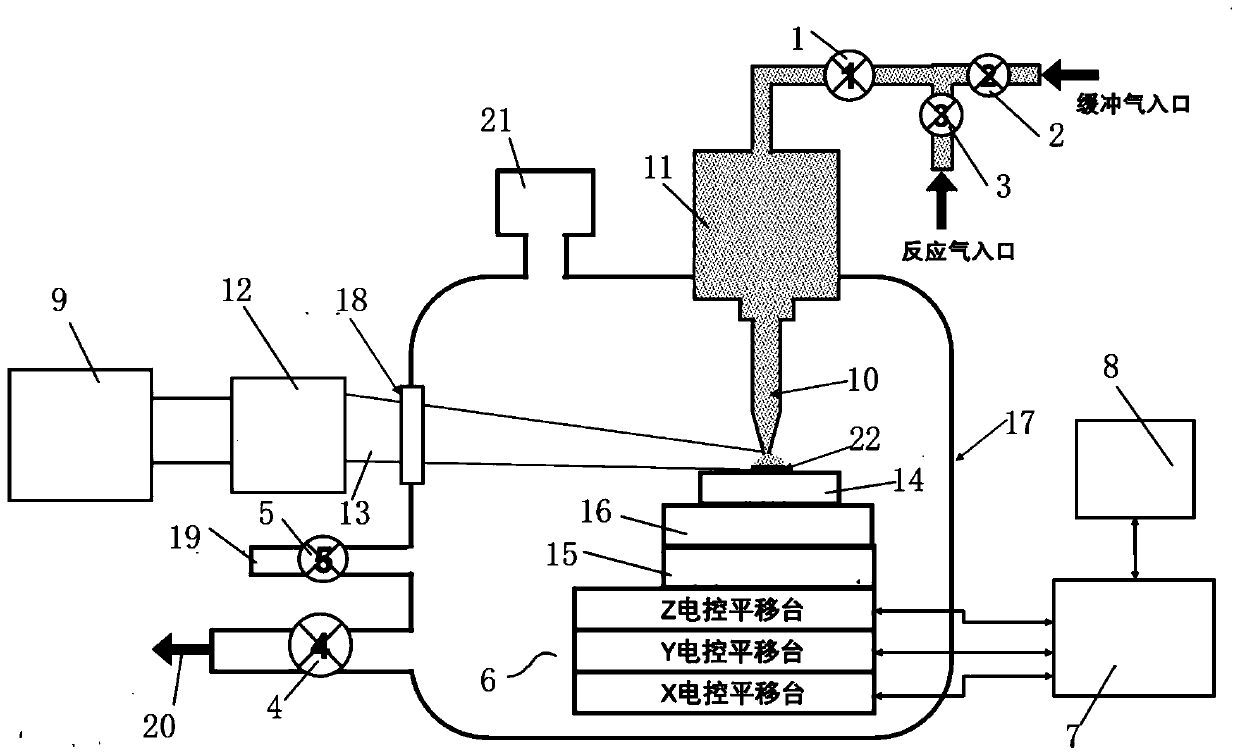

[0064] Specific embodiment one, see figure 1 : the microtube 10 is perpendicular to the surface of the sample 14 and the converging light beam 13 is irradiated on the lower part of the tip of the microtube 10 from the side with a large incident angle; specific embodiment two, see figure 2 : the converging light beam 13 irradiates the surface of the sample 14 vertically and the microtube 10 is nearly parallel to the surface of the sample 14 . In actual system design, the angle between the sample, the microtube and the converging beam can also be adjusted as required.

[0065] The working principle of its micro-nano 3D printing technology based on laser chemical vapor deposition is as follows: the laser beam emitted by the laser converges to the micro-area on the surface of the sample to be processed after passing through the optical element group; the gas cavity is connected to the micro-tube through the adapter; The second flow regulating valve and the buffer gas are mixed a...

Embodiment 1

[0092] This example introduces the deposition of Si along the X direction of the sample based on the laser pyrolysis effect 3 N 4 Nanowires, illustrating one application of the invention.

[0093] test according to Figure 4 configuration, that is, the laser is irradiated perpendicularly to the sample surface. Using CO 2 Laser, the sample is a silicon wafer, and the microtube is a quartz capillary drawn by a needle-pulling instrument, and its tip diameter is about 1 μm. The reaction gas is SiH 4 and NH 3 The mixed gas, the initial volume ratio of the two reaction gases is 1000:1, the specific ratio can be adjusted during work; the buffer gas is argon. The reaction formula of laser chemical vapor deposition is: 3SiH 4 +4NH 3 → Si 3 N 4 +12H 2 ↑

[0094] During the test, the workflow of chemical vapor deposition micro-nano 3D printing in a closed environment was followed. The temperature of the hot stage was controlled at 300-700°C, and the specific temperature value...

Embodiment 2

[0096] This example introduces the deposition of tungsten nanowires along the direction perpendicular to the sample surface based on the laser photolysis effect, and illustrates an application of the present invention.

[0097] test according to image 3 Configuration, that is, the laser convergent beam is incident on the sample surface at a large angle. An ArF laser (wavelength 193nm) is used, the sample is a silicon wafer, and the microtube is a quartz capillary drawn by a needle-pulling instrument, with a tip diameter of about 1 μm. Reactive gas is WF 6 ; The buffer gas is hydrogen; the mixing ratio of the two gases can be adjusted in the test. The reaction formula of laser chemical vapor deposition is: WF 6 +3H 2 →W+6HF↑

[0098] During the test, the workflow of chemical vapor deposition micro-nano 3D printing in a closed environment was followed. When adjusting the laser beam spot, it should be ensured that the laser beam spot is always irradiated at the lower part of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com