A varnish that can be used for uv printing

A varnish and photoinitiator technology, applied in coatings, polyester coatings, polyurea/polyurethane coatings, etc., can solve the problems that the printed pattern does not have a protective effect, the three-dimensional pattern loses its gloss and color, and the gloss is lost. Reduce the scrap rate of print heads, good color and gloss, and prevent the aging effect of varnish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in further detail now in conjunction with embodiment.

[0029] The varnish that can be used for UV printing is prepared by the following method: Weigh the components in proportion, first mix the acrylic resin and the modified monomer at 60°C, and then add additives, Color retention agent and photoinitiator, after each raw material is added, stir evenly before adding the next raw material, after all the raw materials are added, stir evenly.

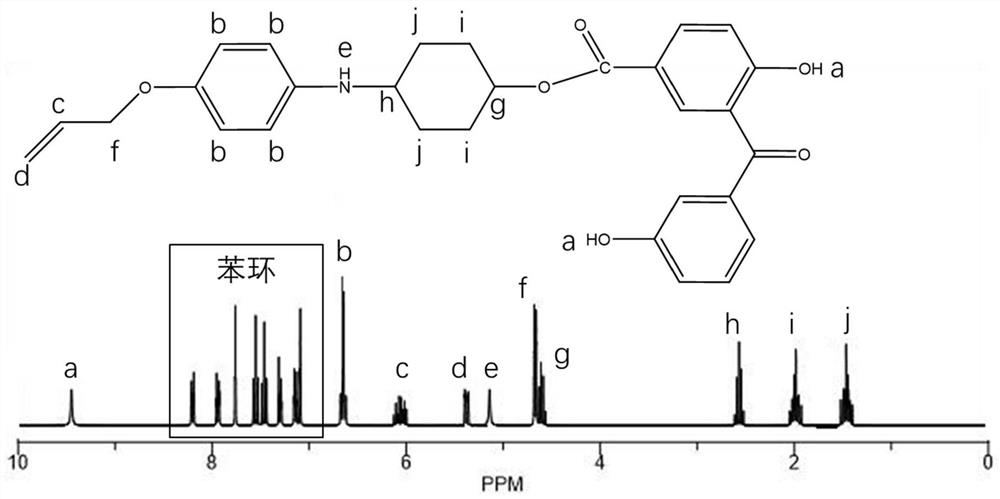

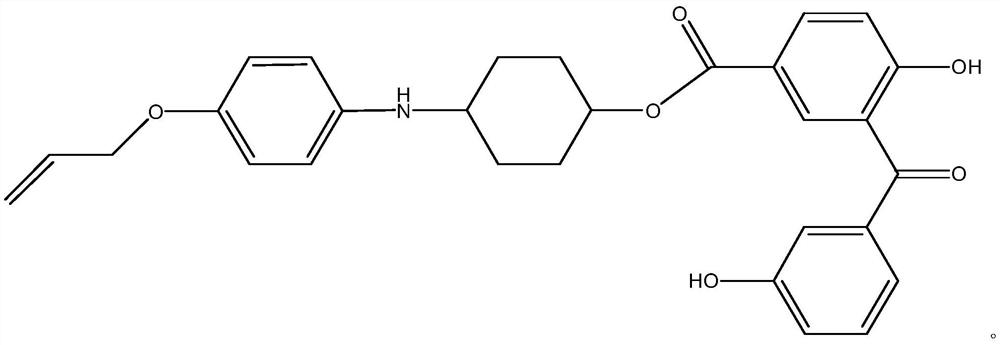

[0030] figure 1 Be the nuclear magnetic resonance spectrogram of color retention agent (product II) of the present invention, nuclear magnetic data is as follows (CDCl 3 as solvent): δ=9.41~9.45 (a, 2H), δ=7.14~8.20 is the characteristic absorption peak of the hydrogen atom on the benzene ring of 4-hydroxyl-3-(3-hydroxybenzoyl) benzoic acid, δ= 6.61~6.64(b, 4H), δ=6.02~6.07(c, 1H), δ=5.31~5.34(d, 2H), δ=5.13~5.16(e, 1H), δ=4.65~4.70(f, 2H), δ=4.56~4.60(g, 1H), δ=2.55~2.61(h, 1H), δ=1.95~1.99(i, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com