A spray-molded two-component polyurea skin and its preparation method

A two-component, surface technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problem that the surface cannot be matte

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

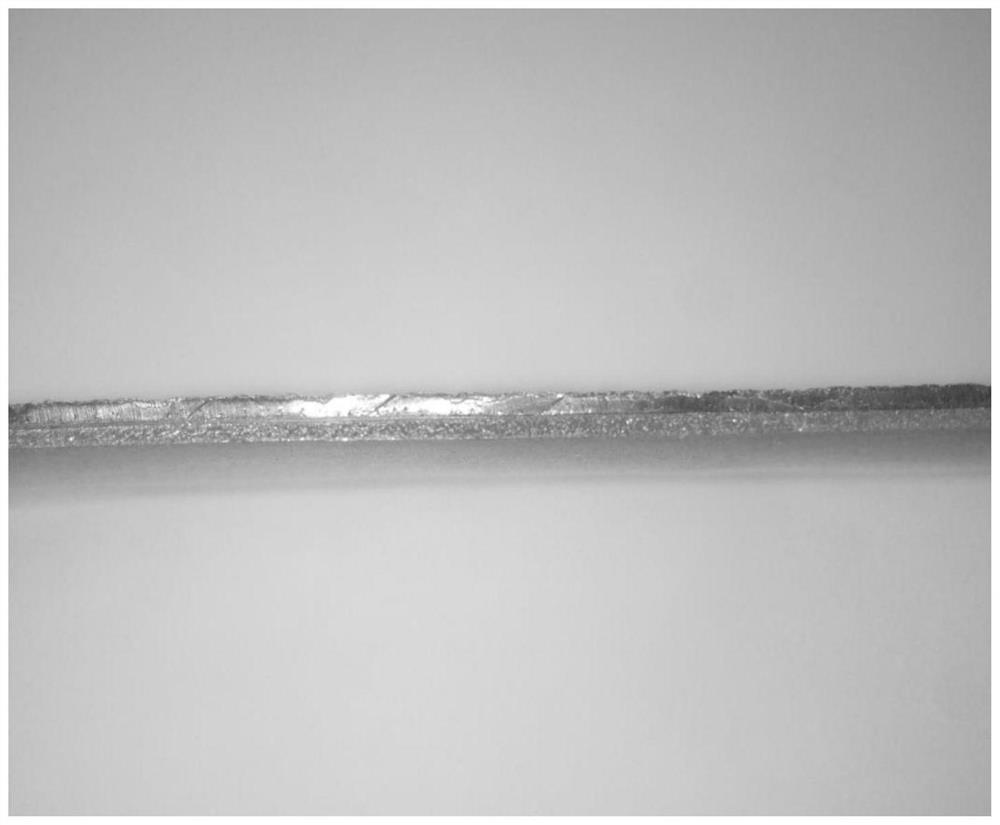

[0089] The present invention also provides a method for preparing a two-component polyurea skin that can be used as an automobile instrument panel skin by spraying and forming described in the above technical solution, comprising the following steps:

[0090] 1) Reaction of aromatic isocyanate with polyether polyol (or polyester polyol) to prepare a semi-prepolymer containing isocyanate functional group at the end or reacting aliphatic isocyanate with amino-terminated polyether to prepare a semi-prepolymer with isocyanate functional group at the end semi-prepolymer, and then mix the semi-prepolymer with isocyanate functional group at the end with diluent to obtain component A;

[0091] 2) After mixing amino-terminated polyether, amino-terminated chain extender, matting powder, colorant, flame retardant, anti-settling agent, leveling agent, defoamer, ultraviolet light absorber, antioxidant, and fungicide Grinding, when the fineness of grinding is less than 300 mesh, the B compo...

Embodiment 1

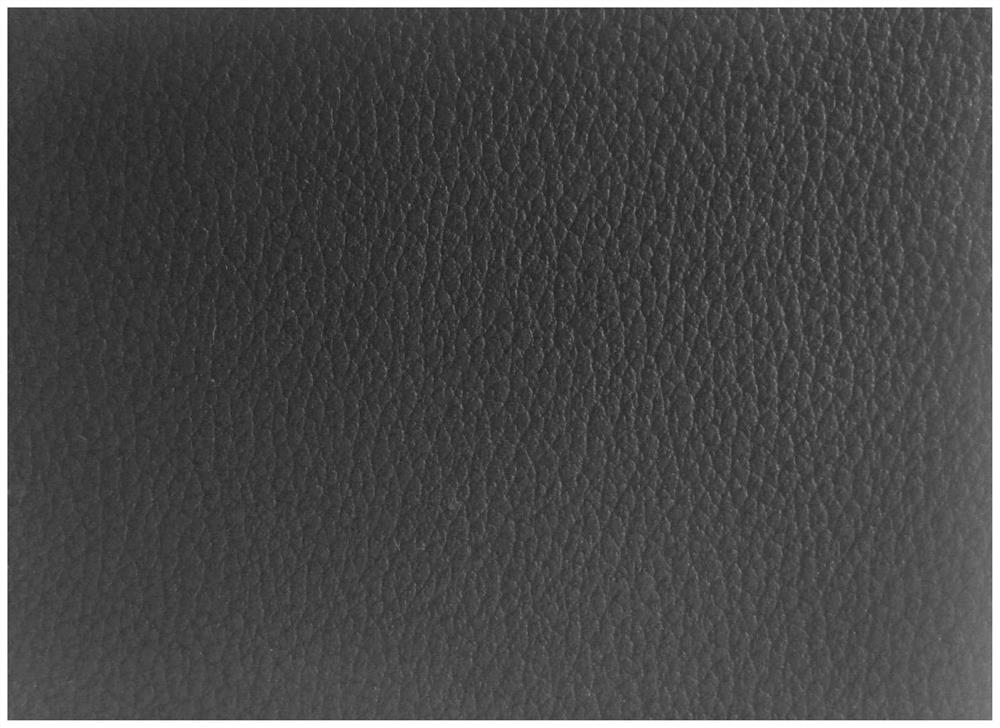

[0103] Example 1: Spraying of single-layer aromatic polyurea and preparation of skin

[0104] Preparation of A component: after containing 50wt% 3051 (a mixture of 2,4'-diphenylmethane diisocyanate and 4,4'-diphenylmethane diisocyanate, wherein the content of 2,4'-diphenylmethane diisocyanate is 50%, American Huntsman Company) In the there-necked flask, feed nitrogen, heat up to 45°C, start to drop 38.4wt% low unsaturation polyoxypropylene ether glycol ( Polyol3205, Germany Covestro company) and 9.6wt% low unsaturation polyoxypropylene ether trihydric alcohol ( Polyol6300, German Covestro company), after adding, gradually warming up to 75 ℃, continue to react for 3~4 hours, then the mass percentage composition (NCO%) of the isocyanate functional group of sampling measurement semi-prepolymer is 15.8%; 98wt% After the semi-prepolymer and 2wt% diluent ethylene carbonate (trade name JS 1002, Beijing Biolab Technology Co., Ltd.) are stirred evenly, component A is obtained, whi...

Embodiment 2

[0111] Example 2: Spraying of single-layer aromatic polyurea and preparation of skin

[0112] The preparation of A component: the MDI semi-prepolymer Isonate240 (NCO% is 18.7%) of the polyester diol modification of U.S. Dow chemical company;

[0113] Preparation of component B: mix 44wt% amino-terminated polyoxypropylene ether (35.5wt% difunctional amino-terminated polyoxypropylene ether D-2000 and 8.5 wt% trifunctional amino-terminated polyoxypropylene ether T-5000, U.S. Huntsman company), 46.5wt% amine chain extender (U.S. Huntsman company's 754), 2.0wt% matting powder (fumed silica Aerosil 200, Germany Degussa company), 2wt% color paste (polyurea special color paste, black, SPUA-6861, Dongguan Jifeng Plastic Materials Co., Ltd.), 2.5wt % flame retardant (dimethyl methyl phosphonate DMMP, Qingdao Lianmei Chemical Co., Ltd.), 1wt% anti-settling agent (oxidized polyethylene anti-settling agent 4200-20, Japan KUSUMOTOCHENICALS company), 0.5wt% leveling agent ( Polyether s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com