Electric power supplying device and harness routing structure using the same

A power supply, flat wire technology, applied in arrangements using take-up reels/photosensitive drums, arrangements using expandable carriers, cable arrangements between relatively moving parts, etc., can solve redundant length absorption performance variations. It can improve the absorption function of redundant length or the absorption performance of redundant length, and improve the absorption performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

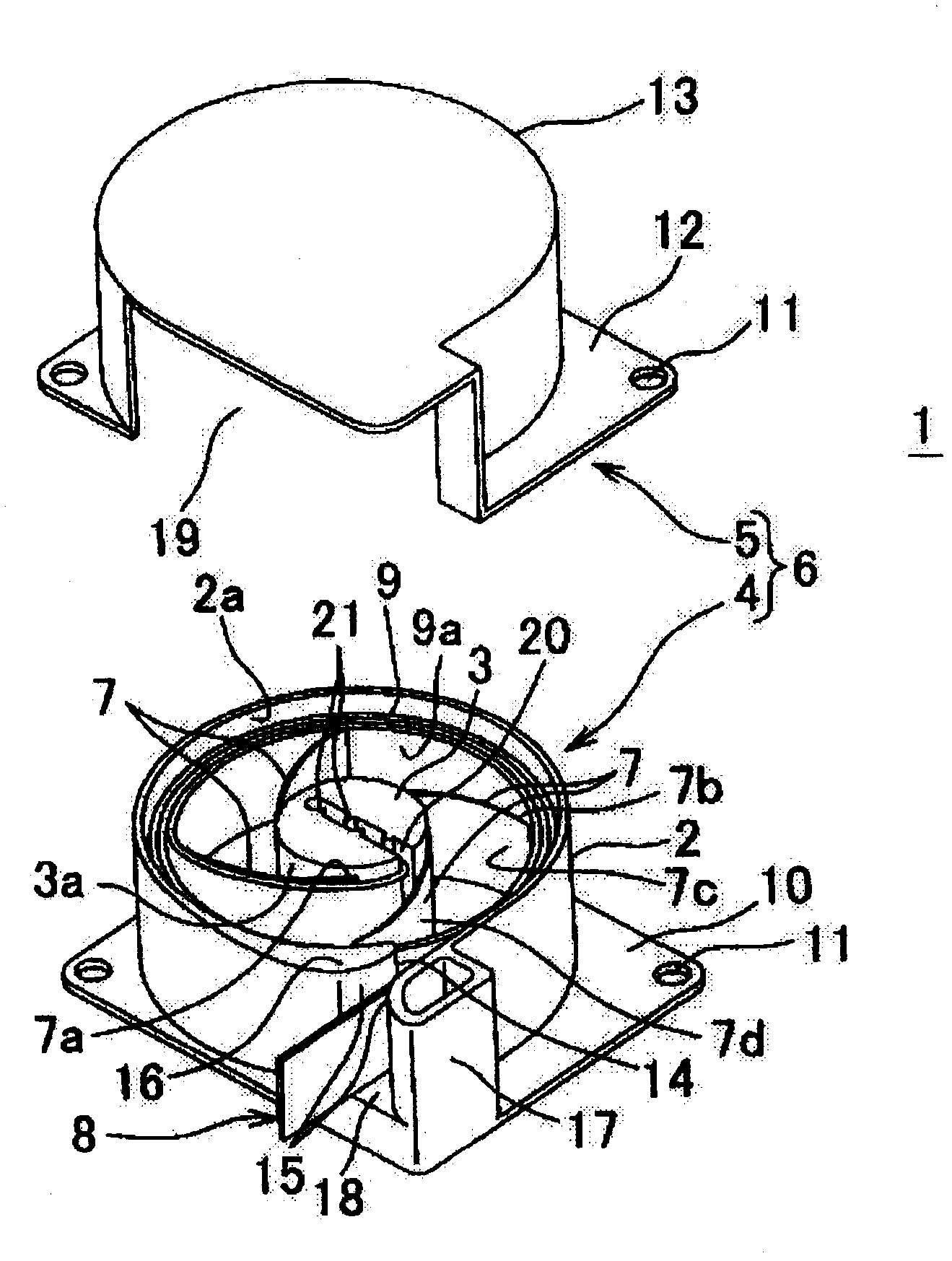

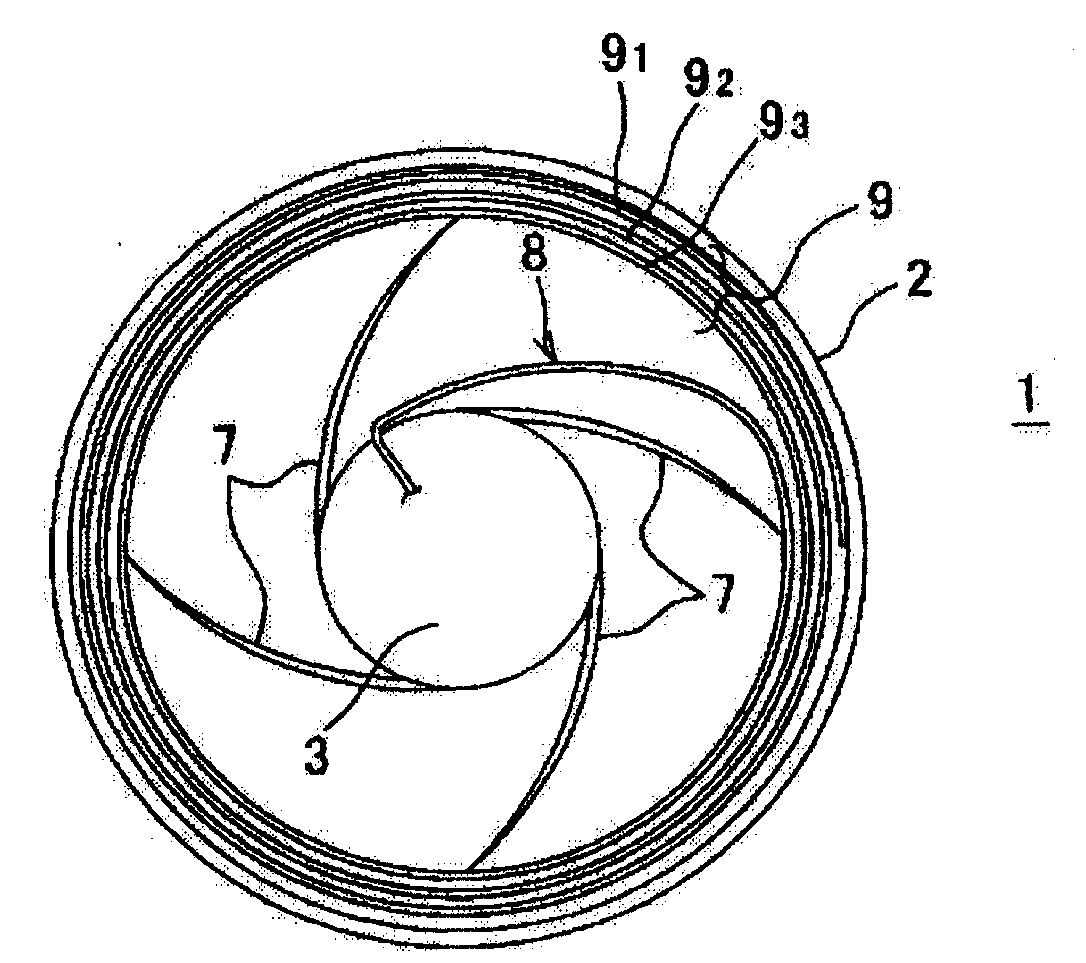

[0067] Figure 1 to Figure 2 An exemplary embodiment of a power supply device according to the invention is shown.

[0068] Such as figure 1 As shown, the power supply device 1 includes: a housing 6 made of synthetic resin and having a circular annular portion (annular wall) 2 and a cylindrical boss portion 3 as its center; a plurality of plate-shaped spring members 7 radially arranged on the outer periphery; and a flexible flat wire harness 8 accommodated in a state in which the inner diameter portions 9a of the winding portions 9 are respectively pushed by the spring members 7 and the flat wire harness The diameter increases annularly along the inner peripheral surface 2 a of the annular portion 2 .

[0069] The housing 6 has a base 4 and a cover 5 . The base portion 4 is preferably integrally formed with the annular portion 2 and the boss portion 3 vertically provided on the base plate portion 10 . The cover portion 5 is formed by a horizontal base plate portion 12 whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com