Method for preparing polyisocyanate through photochemical reaction, and method for preparing waterborne polyurethane resin

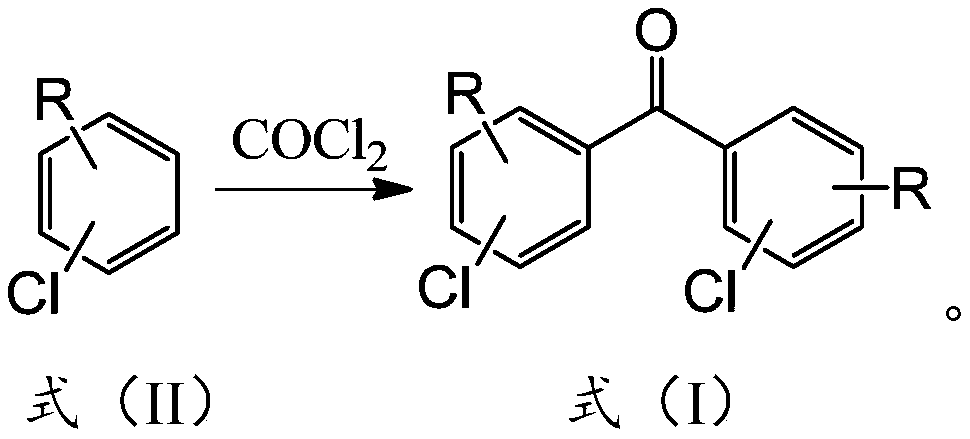

A polyisocyanate and reaction technology, applied in the field of water-based polyurethane resin, can solve the problems of yellowish color and high chlorine content of polyisocyanate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

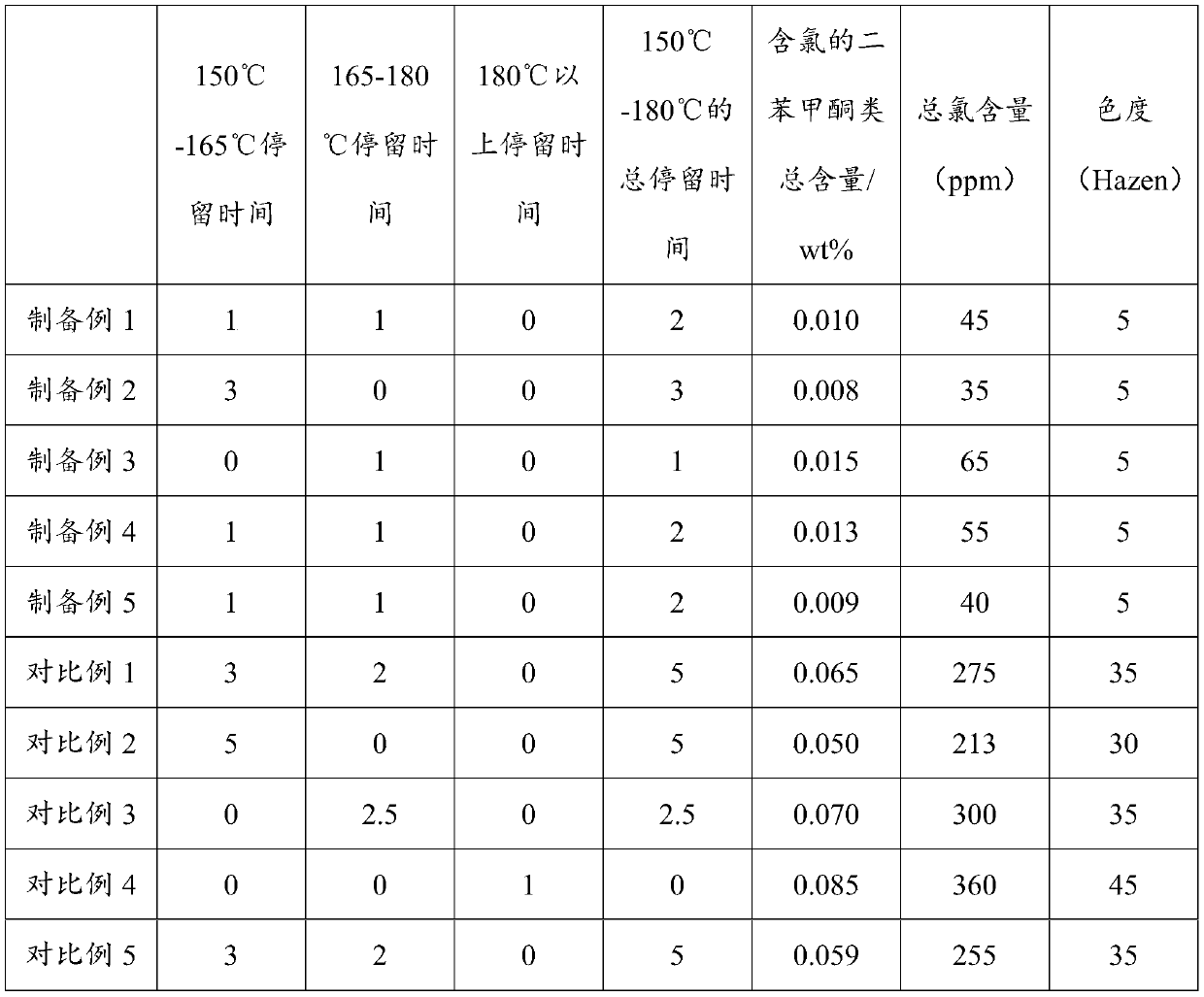

Examples

preparation example 1

[0098] a) Using the heater disclosed in Example 1 of Chinese patent application CN105214568A, diamine H 12 MDA is gasified and heated to 355°C. Under the protection of nitrogen, gaseous phosgene heated to 355°C is continuously added to the reactor through the respective feed tubes for phosgenation reaction; the reaction pressure is absolute pressure 0.05MPa, the reaction temperature is 360℃; where, H 12 The feed rate of MDA is 800Kg / h, and the feed rate of gaseous phosgene is 3000Kg / h; Adopt o-dichlorobenzene solution to pass through the gas jet absorption device that the mixed gas gained after the reaction is cooled rapidly (contact time is about 10s) to 100°C, the product containing H 12 The crude product of MDI, phosgene and o-dichlorobenzene solution; the reaction tail gas enters the tail gas absorption tower and is absorbed by -35°C o-dichlorobenzene solution to obtain the o-dichlorobenzene solution containing phosgene.

[0099] b) The crude product obtained in step a) ...

preparation example 2

[0107] The phosgenation reaction of step a) adopts liquid phase phosgenation reaction, and adopts the following steps in the reaction kettle disclosed with reference to Chinese patent document CN103319372B:

[0108] 1) cold reaction: the H 12 MDA uses o-dichlorobenzene as a solvent to configure a solution with a mass content of 15%, and preheats it to 40°C, and simultaneously passes liquid phosgene at -5°C into a reaction kettle containing o-dichlorobenzene solution for liquid phase Phosgenation reaction; where, H 12 The feeding amount of MDA is 400Kg / h, the feeding amount of cold reaction phosgene is 1500kg / h, the cold reaction temperature is controlled at 60°C, and the residence time is 5min;

[0109] 2) Thermal reaction: the temperature is controlled at 155°C, and the residence time is 2h. The reaction is carried out in the presence of o-dichlorobenzene solution and excess phosgene, and the product containing H 12 The reaction solution (crude product) of MDI, phosgene and...

preparation example 3

[0118] The phosgenation reaction of step a) adopts the salt-forming phosgenation reaction, and adopts the following steps in the tank reactor disclosed in the embodiment 1 of the Chinese patent document CN105218422B with reference to:

[0119] 1) Add 1000Kg o-dichlorobenzene in advance as the reaction solvent in the salt-forming reactor, turn on the circulation pump and stir, and the hydrogen chloride compressed gas enters the reactor at a speed of 50mol / min through the pre-mixer, and after stirring for 15min, the H 12 The mixed solution of MDA and o-dichlorobenzene is heated to 30°C through the raw material preheater, and then it is fully contacted with hydrogen chloride gas at a flow rate of 335Kg / h to form a salt reaction; it is cooled by external circulating cooling water to remove part of the heat of reaction and circulate Liquid flow at 5m 3 / h or so, the temperature of the reaction solution is maintained at 30-45°C, and after feeding for 3 hours, stop the H 12 The mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com