A continuous purification method for high-purity tungsten hexafluoride

A technology of tungsten hexafluoride and purification method, which is applied in the direction of tungsten halide, etc., can solve the problems of low purity of tungsten hexafluoride, non-continuous operation, high cost, etc., and achieve excellent purification effect, increase production efficiency, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

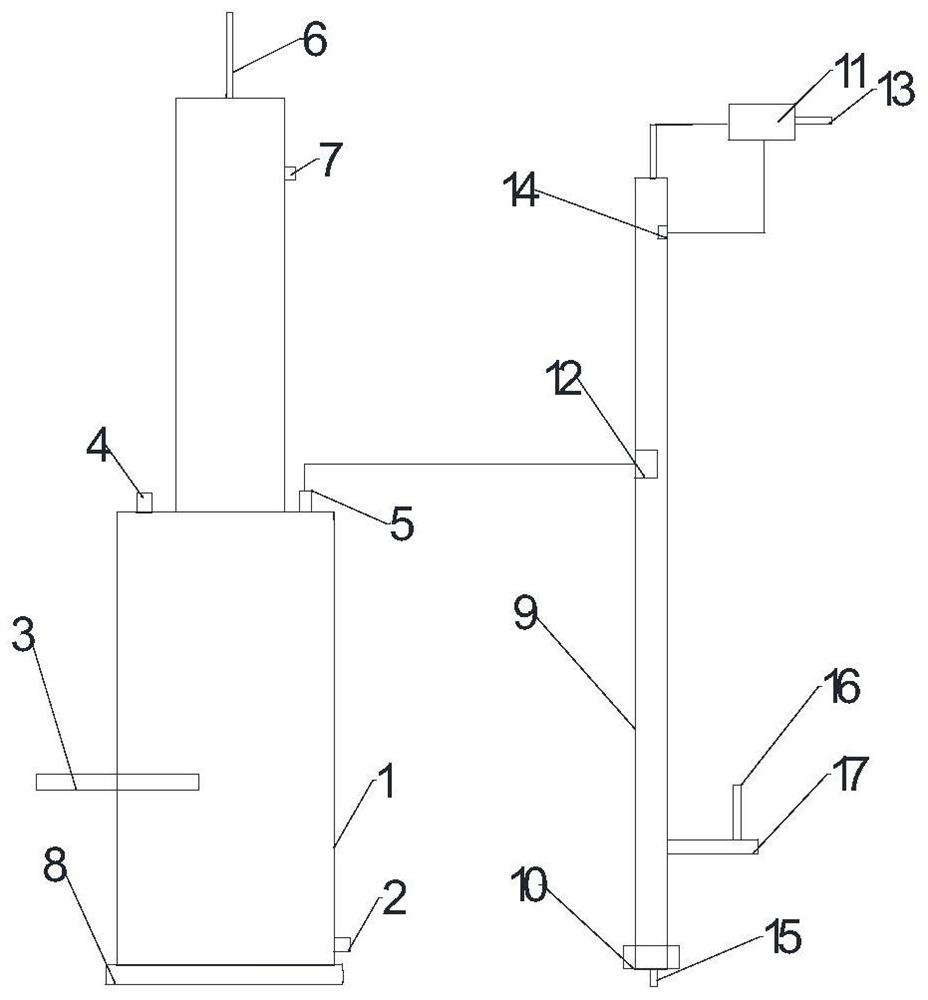

[0033] (1) Continuously fill the cooling circulation system with liquid nitrogen through the cooling medium inlet 2 to maintain the temperature of the low-temperature purification tower 1 at -180°C to -150°C, and vacuum the interior of the low-temperature purification tower 1 to below -0.07MPa ;

[0034] (2) Then, through the feed port I4, the tungsten hexafluoride crude product gas with a purity of 33.1vol% is continuously introduced into the low-temperature purification tower 1 (see Table 1 for its impurity composition and content), and the tungsten hexafluoride gas condenses rapidly. Huacheng solid, when the pressure in the low temperature purification tower 1 is higher than -0.03MPa, open the valve of the vent pipe 6 to release the pressure to -0.05MPa by vacuuming, discharge the impurity gas while releasing the pressure, and then close the vent pipe 6 When the pressure is higher than -0.03MPa again, the valve is repeatedly vented, and when the solid tungsten hexafluoride ...

Embodiment 2

[0043] (1) Continuously fill the cooling circulation system with liquid nitrogen through the cooling medium inlet 2 to maintain the temperature of the low-temperature purification tower 1 at -180°C to -150°C, and vacuum the interior of the low-temperature purification tower 1 to below -0.07MPa ;

[0044] (2) Then, through the feed port I4, the tungsten hexafluoride crude product gas with a purity of 83.2vol% is continuously introduced into the low-temperature purification tower 1 (see Table 3 for its impurity composition and content), and the tungsten hexafluoride gas condenses rapidly. Huacheng solid, when the pressure in the low temperature purification tower 1 is higher than 0MPa, open the valve of the open pipe 6 to release the pressure to -0.02MPa by vacuuming, and discharge the impurity gas while releasing the pressure, then close the valve of the pipe 6, wait When the pressure is higher than 0 MPa again, the emptying is repeated, and when the solid tungsten hexafluoride...

Embodiment 3

[0053] (1) Continuously fill the cooling circulation system with liquid nitrogen through the cooling medium inlet 2 to maintain the temperature of the low-temperature purification tower 1 at -180°C to -150°C, and vacuum the interior of the low-temperature purification tower 1 to below -0.07MPa ;

[0054] (2) Then, through the feed port I4, the tungsten hexafluoride crude product gas with a purity of 65.3vol% is continuously introduced into the low-temperature purification tower 1 (see Table 5 for its impurity composition and content), and the tungsten hexafluoride gas condenses rapidly. Huacheng solid, when the pressure in the low temperature purification tower 1 is higher than -0.01MPa, open the valve of the vent pipe 6 to release the pressure to -0.03MPa by vacuuming, discharge the impurity gas while releasing the pressure, and then close the vent pipe 6 When the pressure is higher than -0.01MPa again, the valve is repeatedly vented, and when the solid tungsten hexafluoride ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com