Cable sheath capable of preventing condensation water from being accumulated for aircraft and fabrication method of cable sheath

A cable sheathing and aircraft technology, which is applied in cable/conductor manufacturing, insulating cables, insulating conductors/cables, etc., can solve the problems of cable freezing, hidden dangers, icing, etc., achieve quick and easy installation and removal, avoid stretch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

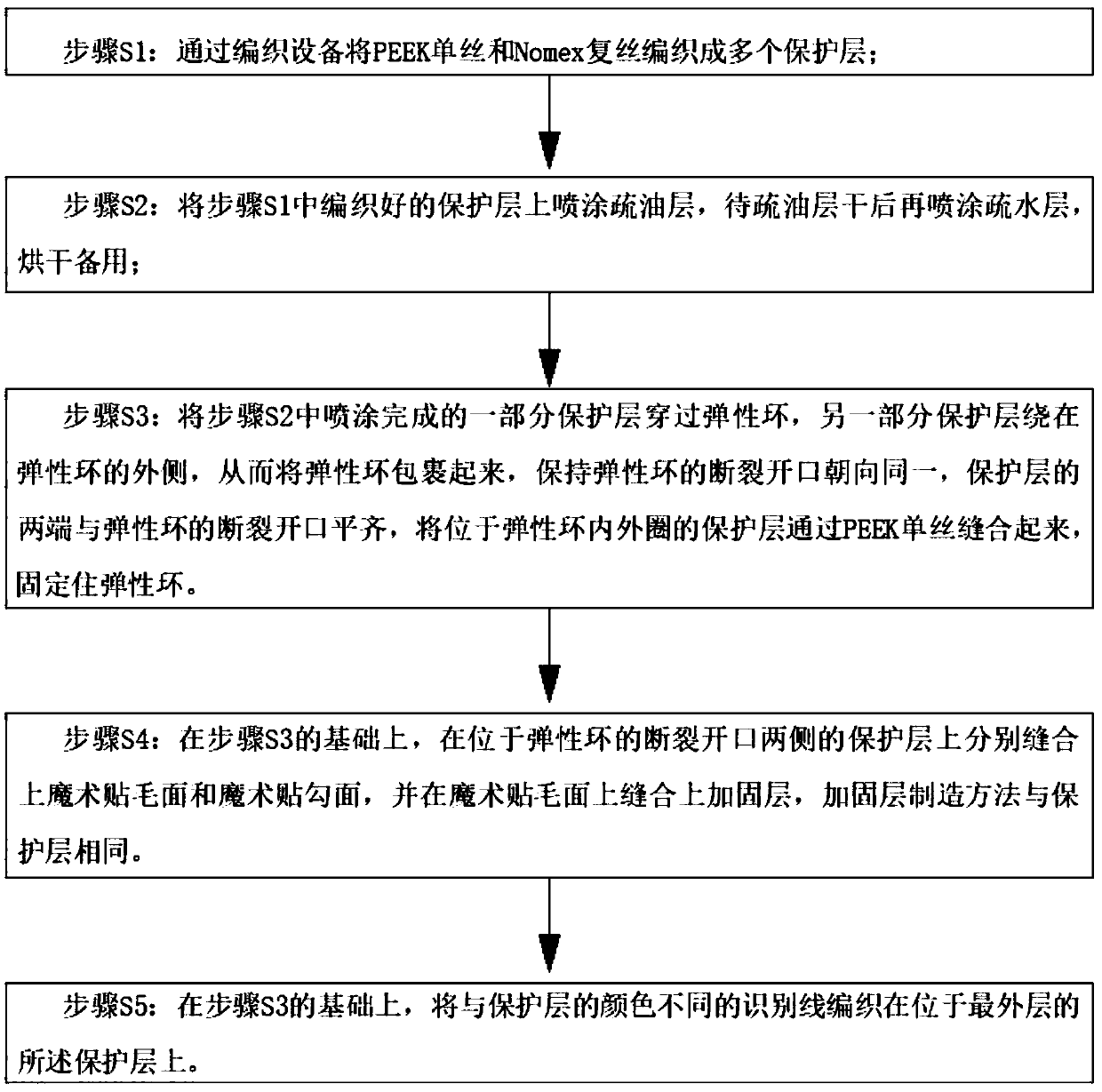

[0026] A method for preparing an aircraft cable sheath capable of preventing condensed water from accumulating, the method comprising the following steps:

[0027] Step S1: Weaving PEEK monofilament and Nomex multifilament into multiple protective layers through braiding equipment;

[0028] Step S2: Spray the oleophobic layer on the protective layer woven in step S1, spray the hydrophobic layer after the oleophobic layer is dry, and dry it for later use;

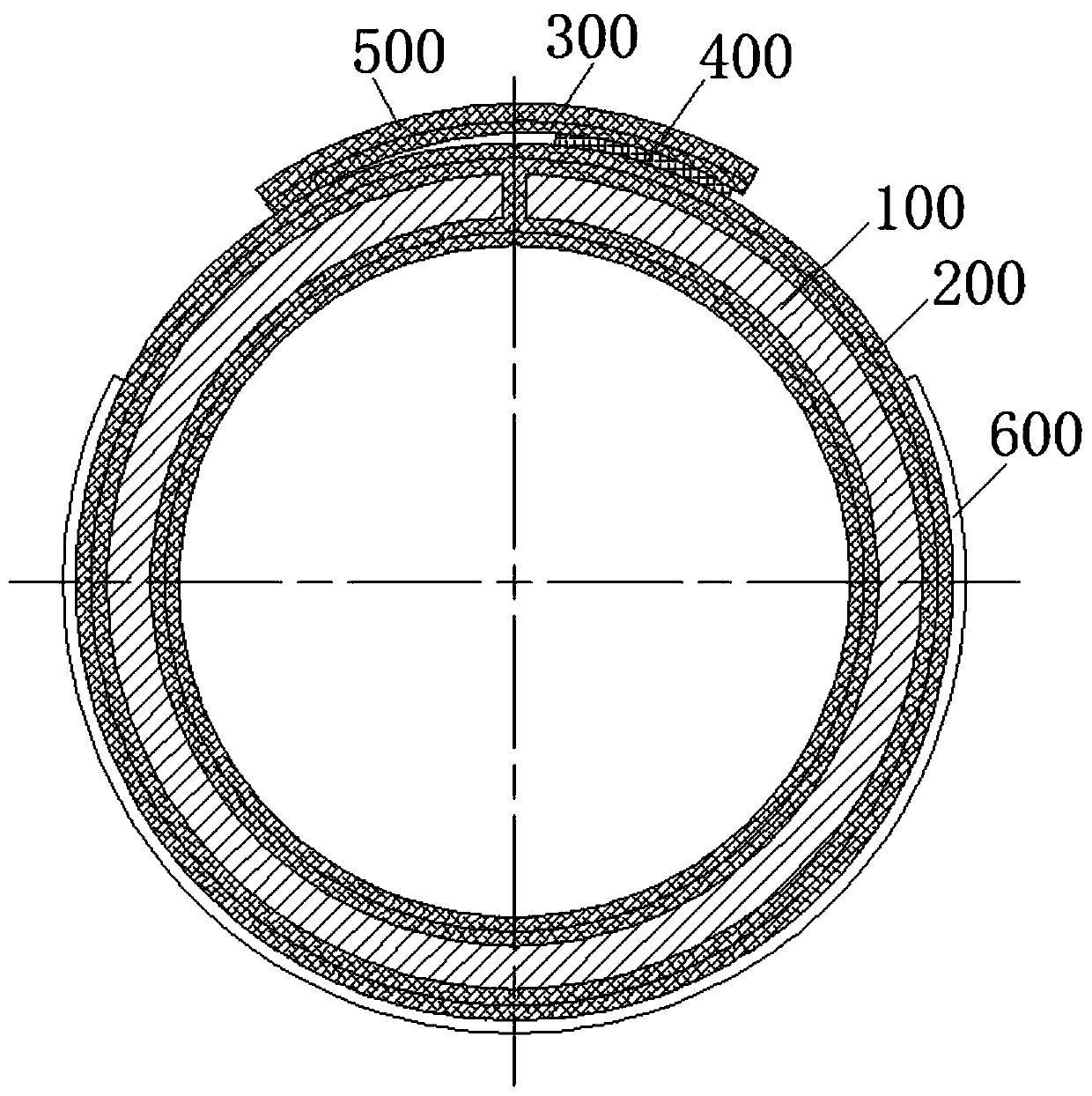

[0029] Step S3: Pass a part of the protective layer sprayed in step S2 through the elastic ring, and wrap the other part of the protective layer around the outer side of the elastic ring, so as to wrap the elastic ring, keep the fracture opening of the elastic ring facing the same direction, and the two ends of the protective layer Align with the break opening of the elastic ring, suture the protective layer on the inner and outer rings of the elastic ring through PEEK monofilament to fix the elastic ring.

Embodiment approach

[0030] As an embodiment of the present invention, the preparation method further includes step S4: on the basis of step S3, on the protective layer located on both sides of the fracture opening of the elastic ring, respectively sew the Velcro rough surface and the Velcro hook surface, and A reinforcement layer is sewed on the wool surface of the Velcro, and the method of manufacturing the reinforcement layer is the same as that of the protective layer.

[0031] As an embodiment of the present invention, the preparation method further includes step S5: on the basis of step S3, weaving an identification thread having a color different from that of the protective layer on the outermost protective layer.

[0032] As an embodiment of the present invention, the identification line is sprayed with a hydrophobic layer and an oleophobic layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com