Photoelectrochromic visualization biosensor based on ratio principle and preparation method and application thereof

A biosensor, color-changing technology, applied in the direction of analysis, instruments, scientific instruments, etc., by causing chemical reactions to occur in materials, can solve the problems of long processing time, high cost, complex equipment requirements for operation technology, etc., and achieve simple and effective detection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

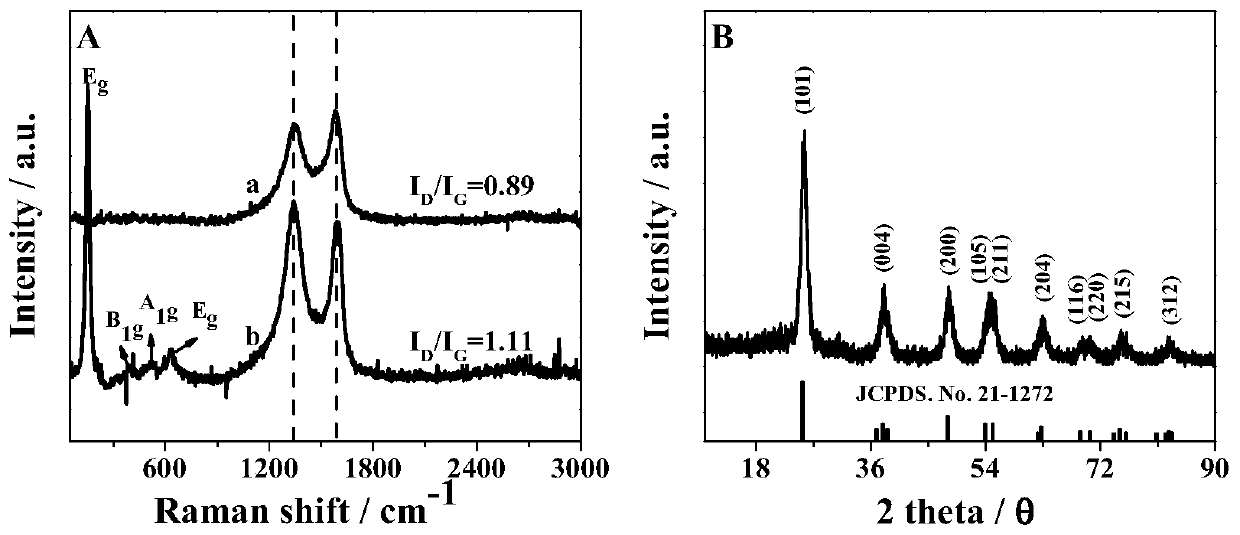

[0033] 1) Co-N-TiO 2 / Preparation of 3DGH nanocomposites and Prussian blue PB solution

[0034] First, cobalt-nitrogen co-doped titania nanoparticles were first prepared as follows: solution A was to place 30 mL of ethanol in a 250 mL round bottom flask and stir. Then, 2.0 g of urea was added as a nitrogen source. In addition, 0.05 g of cobalt nitrate was added to the round bottom flask. Finally, 2 mL of ultrapure water was added thereto. Solution B is to add 30mL ethanol and 3mL HNO respectively to another 250mL round bottom flask 3 . Finally, 10 mL of TBT was slowly added to the above solution and stirred for half an hour. Solution B was added dropwise to solution A at a rate of 1 mL / min, and then stirred for 120 min. After the mixed solution was stirred, it was transferred to a 100 mL autoclave and heated in an oven at 120° C. for 16 h. Then it was washed several times with ultrapure water and dried overnight in an oven at 100 °C. Finally, the obtained sample was p...

Embodiment 2

[0043] 1) Co-N-TiO 2 / Preparation of 3DGH nanocomposites and Prussian blue PB solution

[0044] First, cobalt-nitrogen co-doped titania nanoparticles were first prepared as follows: solution A was to place 30 mL of ethanol in a 250 mL round bottom flask and stir. Then, 2.0 g of urea was added as a nitrogen source. In addition, 0.05 g of cobalt nitrate was added to the round bottom flask. Finally, 2 mL of ultrapure water was added thereto. Solution B is to add 30mL ethanol and 3mLHNO respectively to another 250mL round bottom flask 3 . Finally, TBT was slowly added to the above solution and stirred for half an hour. Solution B was added dropwise to solution A at a rate of 1 mL / min, and then stirred for 120 min. After the mixed solution was stirred, it was transferred to a 100 mL autoclave and heated in an oven at 120° C. for 16 h. Then it was washed several times with ultrapure water and dried overnight in an oven at 100 °C. Finally, the obtained sample was placed in a...

Embodiment 3

[0053] 1) Co-N-TiO 2 / Preparation of 3DGH nanocomposites and Prussian blue PB solution

[0054] First, cobalt-nitrogen co-doped titania nanoparticles were first prepared as follows: solution A was to place 30 mL of ethanol in a 250 mL round bottom flask and stir. Then, 2.0 g of urea was added as a nitrogen source. In addition, 0.05 g of cobalt nitrate was added to the round bottom flask. Finally, 2 mL of ultrapure water was added thereto. Solution B is to add 30mL ethanol and 3mLHNO respectively to another 250mL round bottom flask 3 . Finally, TBT was slowly added to the above solution and stirred for half an hour. Solution B was added dropwise to solution A at a rate of 1 mL / min, and then stirred for 120 min. After the mixed solution was stirred, it was transferred to a 100 mL autoclave and heated in an oven at 120° C. for 16 h. Then it was washed several times with ultrapure water and dried overnight in an oven at 100 °C. Finally, the obtained sample was placed in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com