Control system of waste heat recovery type oil-injected screw compressor and control method thereof

A screw compressor and control system technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of complex structure, large energy consumption, low degree of automation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

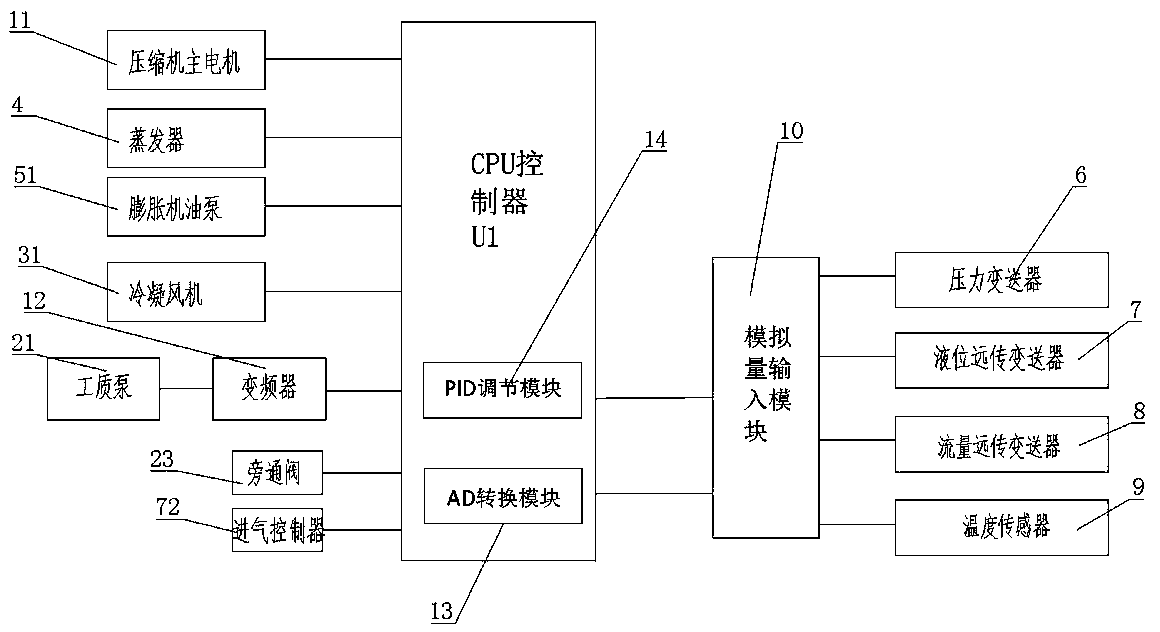

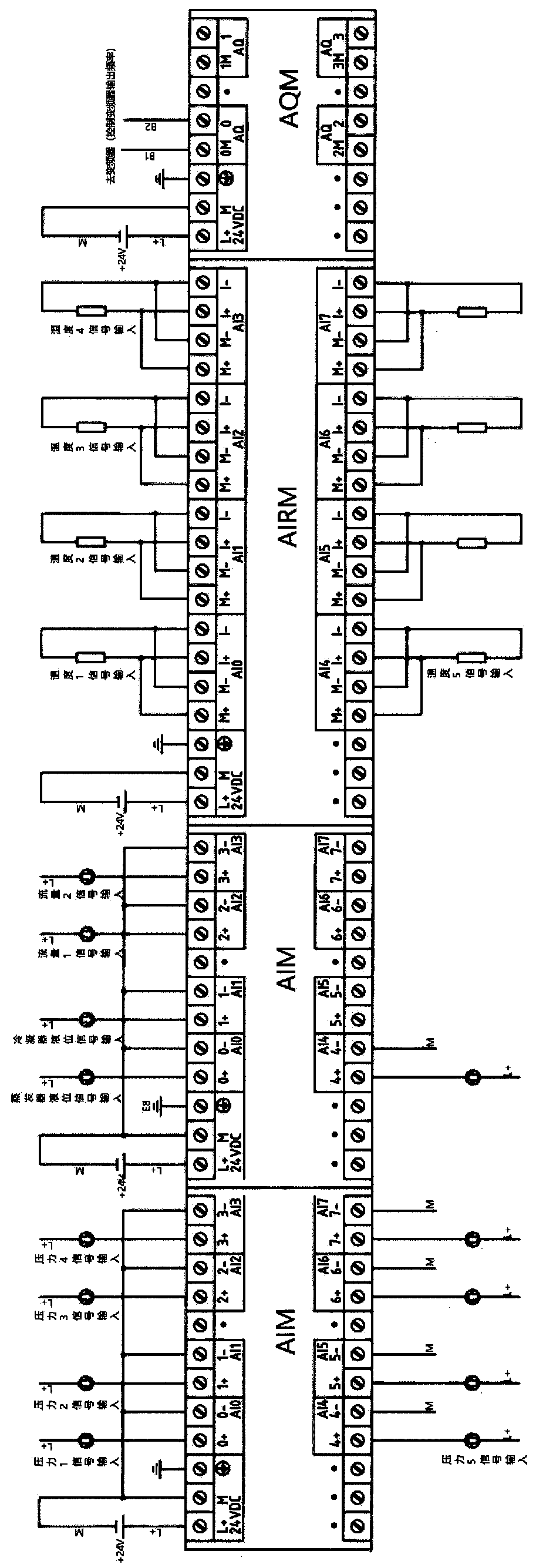

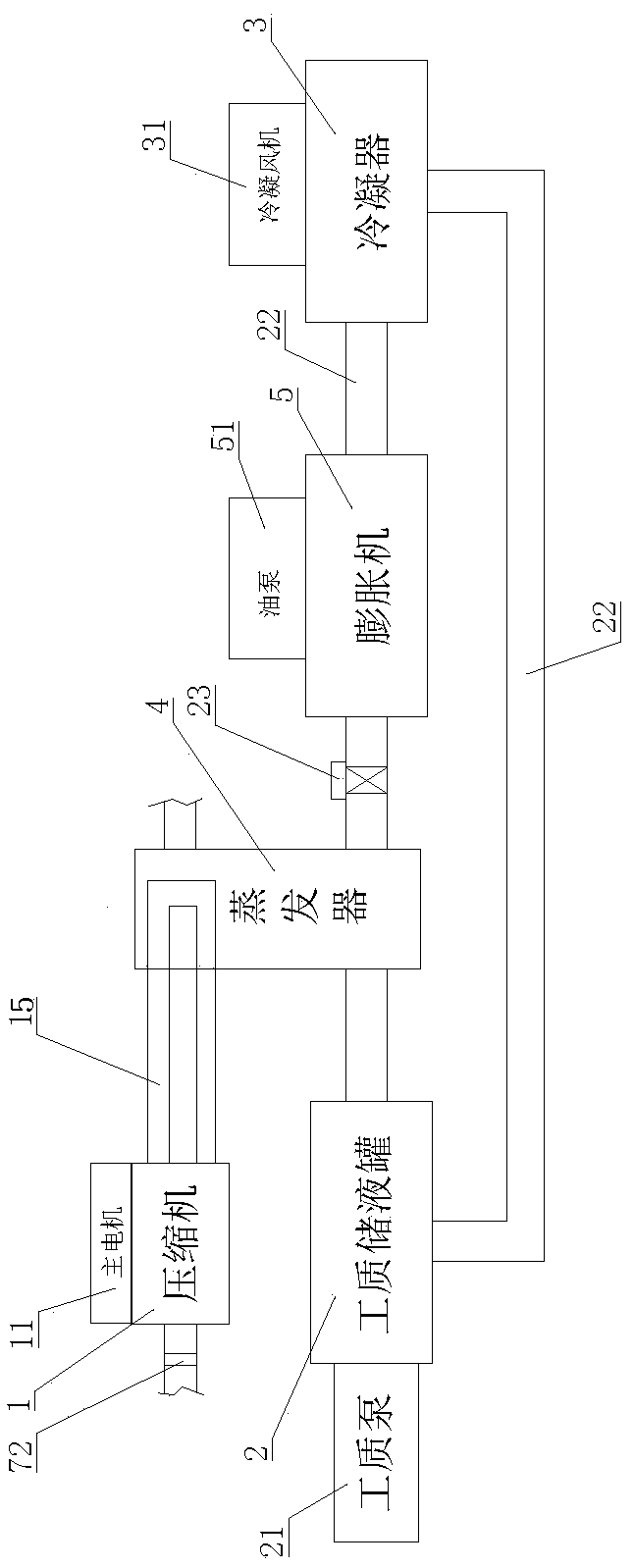

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4, a waste heat expansion power recovery type oil-injected screw compressor control system, which includes a CPU controller U1, the CPU controller U1 is connected to a power module, and the power module includes a compressor main motor 11, a working medium pump 21, a condensing fan 31, an expansion An oil pump 51, an air intake controller 72 is provided at the intake pipe of the compressor 1, the working medium pump 21 is used to drive the flow of the working medium in the working medium storage tank 2, and the compressor main motor 11 is used to drive the compressor 1, The condenser fan 31 is used to drive the condenser 3, and the expander oil pump 51 is used to drive the expander 5, which also includes a detection module, which includes a pressure transmitter 6, a liquid level remote transmitter 7, a flow remote transmitter 8, temperature sensor 9, compressor 1, working fluid storage tank 2, evaporator 4, and expand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com