The Compensation Method for Rotation Error Measurement of Rotary Table Boring

A technology of rotation error and compensation method, which is used in measuring/indicating equipment, metal processing equipment, other manufacturing equipment/tools, etc. Accuracy function Hole coaxiality requirements at both ends of the hole, improving accuracy, and the effect of great practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

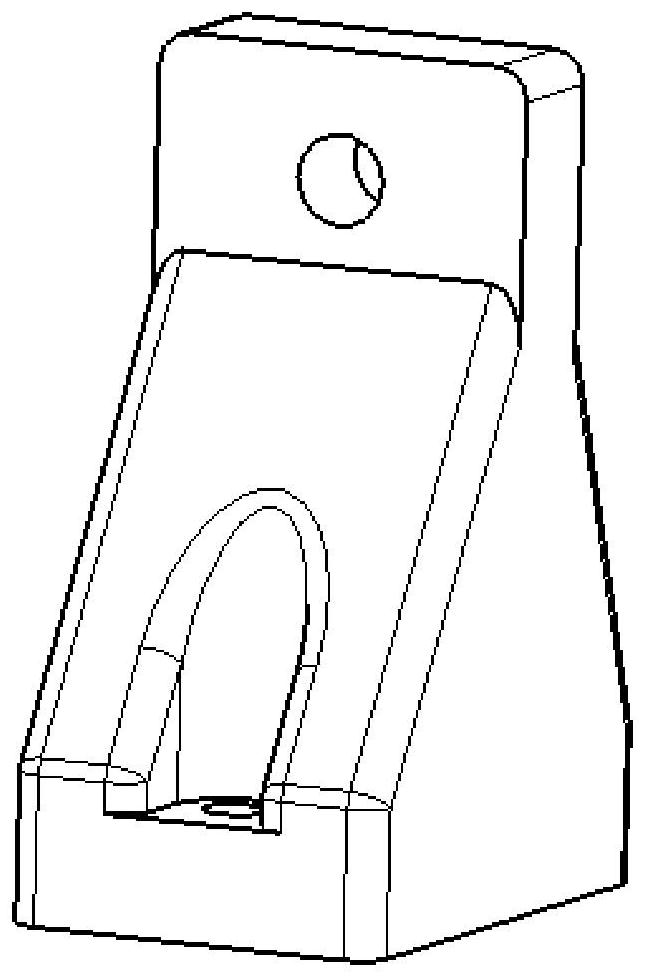

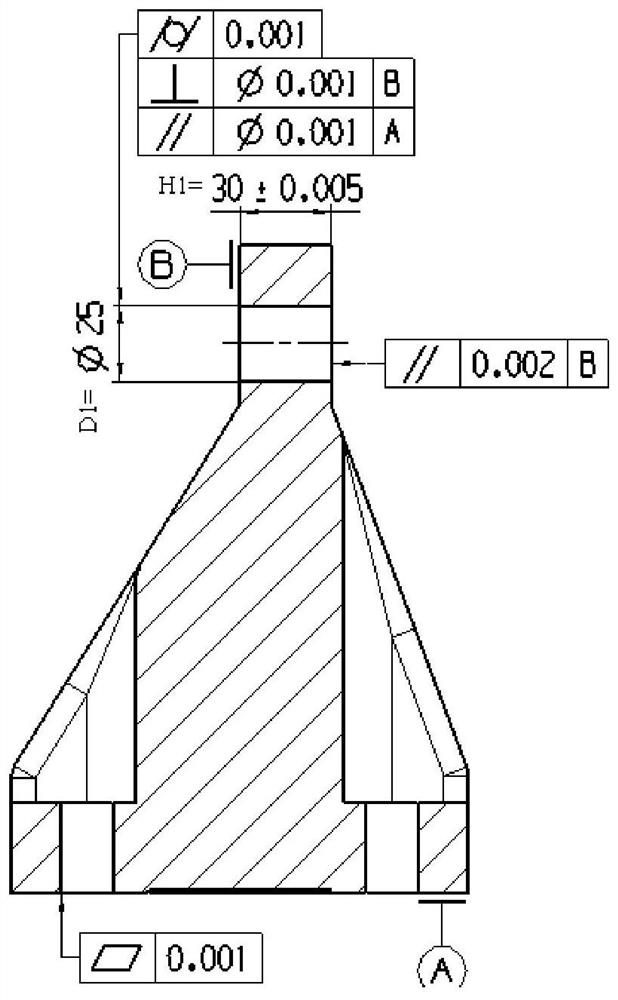

[0026] figure 1 It is a structural schematic diagram of the rotary aligning body of the present invention, figure 2 It is a sectional view of the rotary aligning body of the present invention, as figure 1 and figure 2 As shown, the diameter D1 of the alignment hole is φ25mm, the hole depth H1 is 30±0.005mm, the cylindricity is 0.001mm, the perpendicularity between the alignment hole and the end surface B is 0.001mm, and the parallelism between the two end surfaces B is 0.002 mm. After the rotary aligning body is made, it can be used repeatedly for a long time without loss of accuracy and function.

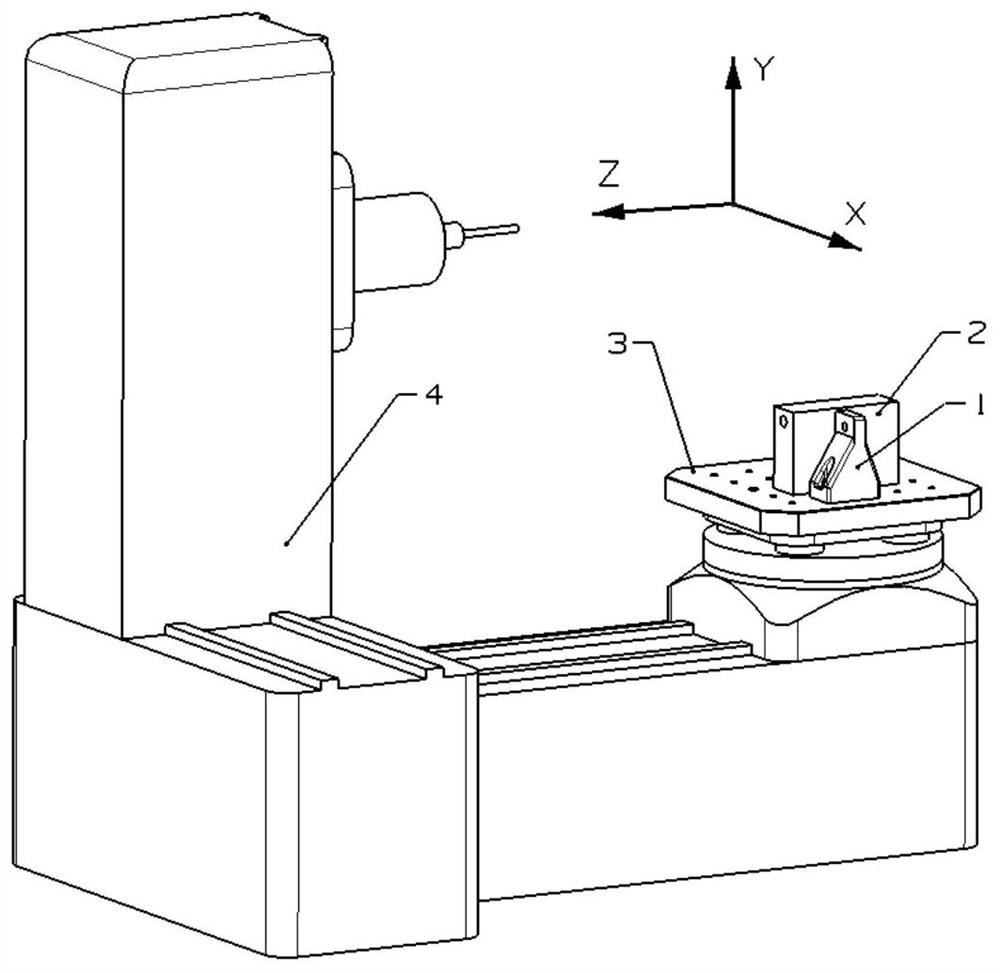

[0027] image 3 It is a schematic diagram of the installation of the rotary aligning body and the processed parts on the machine tool of the present invention. Press the rotary alignment body 1 image 3 As shown, it is fixed on the turntable 3 of the machine tool. Use a dial gauge to straighten the surface B of the rotary alignment body within 0.001mm, straighten the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com