High-precision vertical lathe with small occupied space

A vertical lathe technology that occupies a lot of space. It is applied in the direction of automatic lathes/semi-automatic lathes, turning equipment, turning equipment, etc. It can solve problems such as waste chips interfering with lathe processing, waste blocking protection, and affecting product qualification rate. The effect of avoiding adverse effects, increasing the occupied space, and reducing the difficulty of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

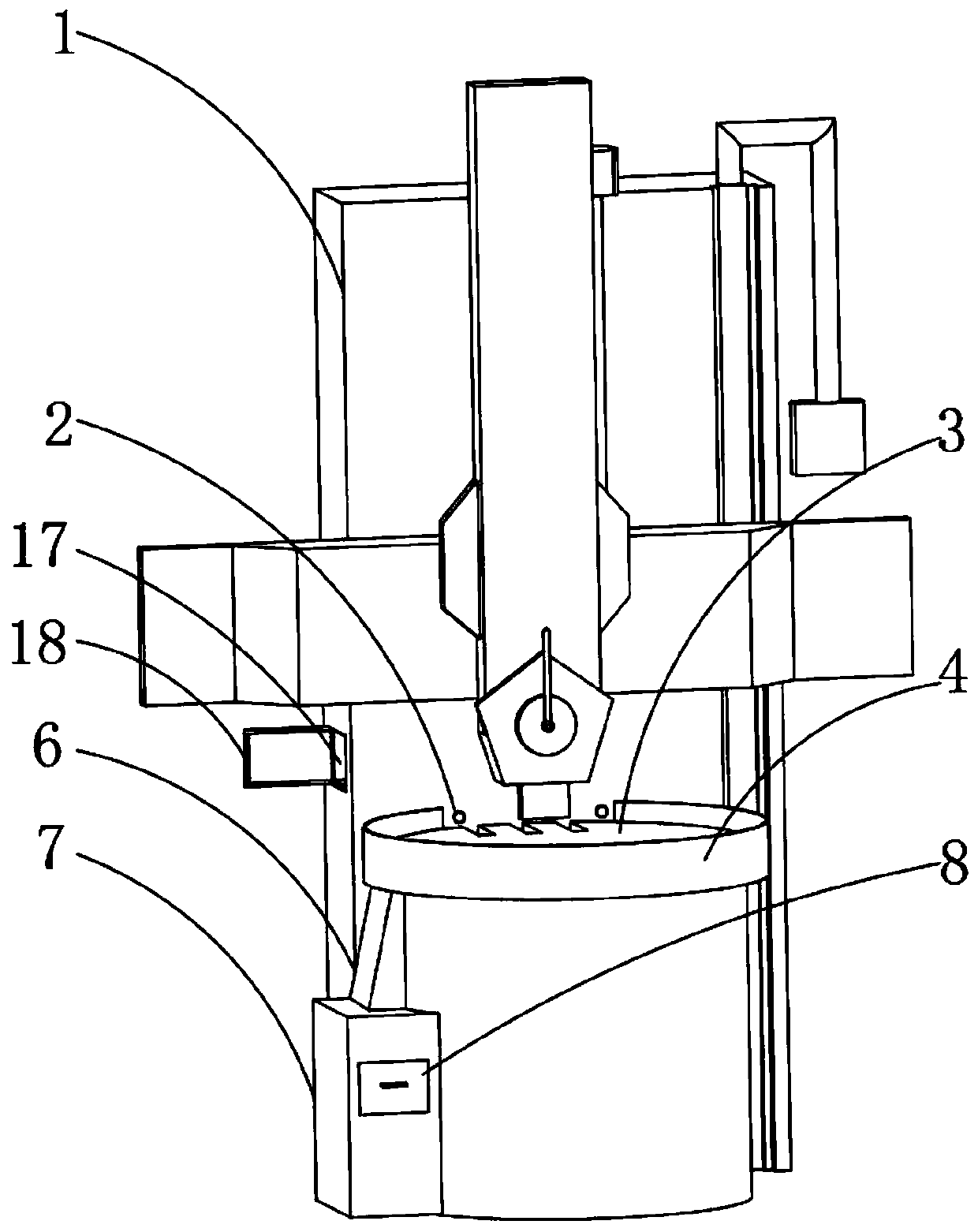

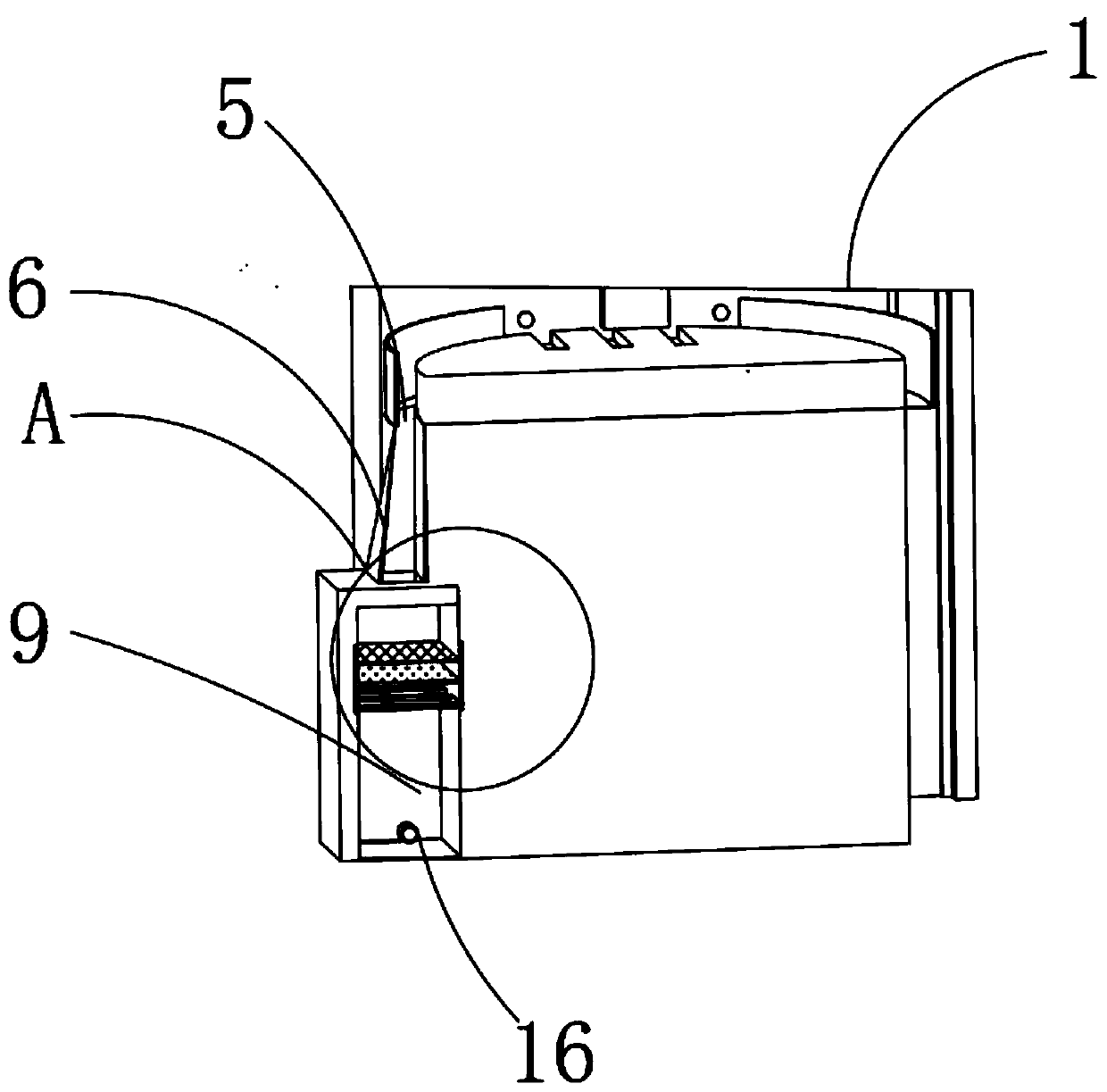

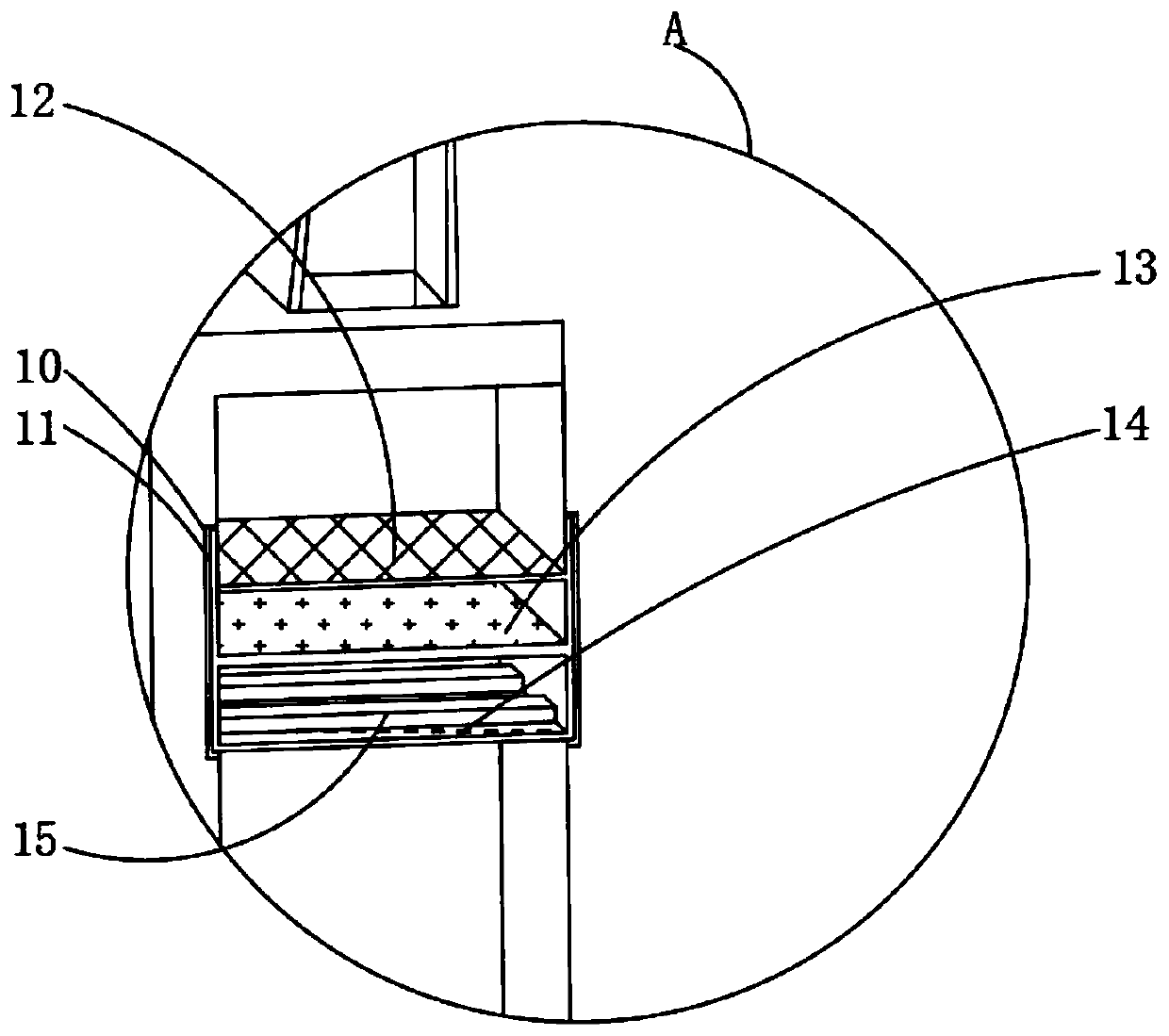

[0027] Example: such as Figure 1-4 As shown, the present invention provides a technical solution, a high-precision vertical lathe with a small footprint, comprising a vertical lathe 1, a nozzle 2 is installed in the middle of the front of the vertical lathe 1, and one end of the nozzle 2 is connected to a water inlet pipe, and One end of the water inlet pipe is connected to a decontamination solvent tank. By pouring an appropriate amount of decontamination solvent into the decontamination solvent tank, the nozzle 2 sprays the decontamination solvent to clean the processing table 3, reducing the difficulty of cleaning for the user. Vertical lathe 1. A processing tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com