A water glass carbon dioxide hardened molding sand suitable for casting alkaline high manganese steel casting materials

A technology of carbon dioxide and high manganese steel, applied in casting molding equipment, casting molds, cores, etc., can solve the problems of high thermal expansion rate and poor collapsibility, achieve smooth surface, good reusability and collapsibility, and overcome sticky sand The effect of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

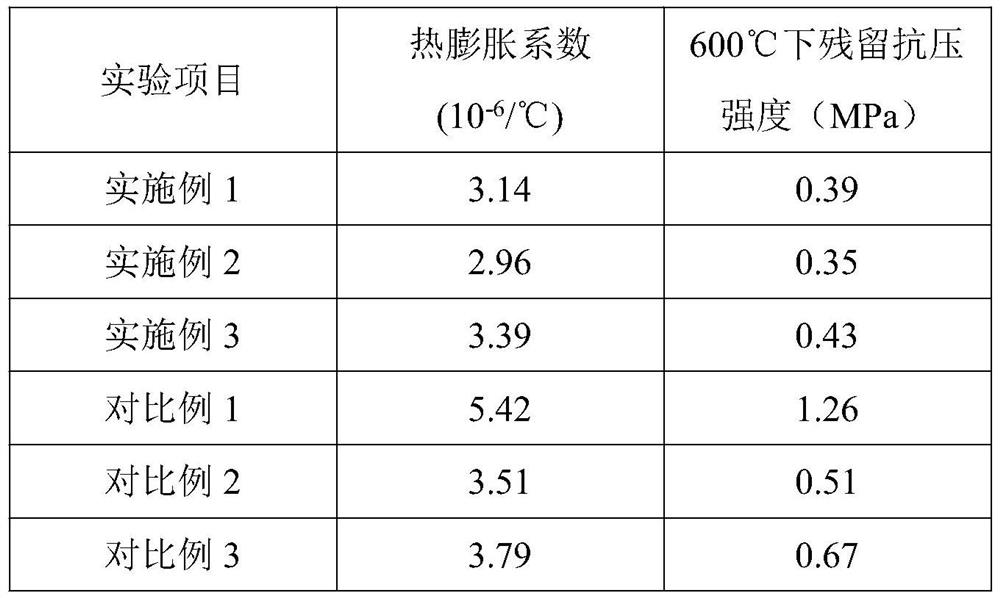

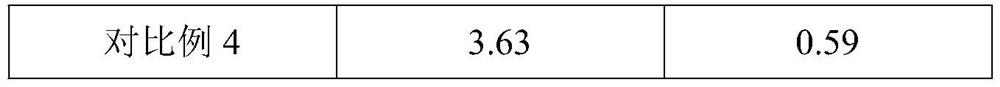

Examples

preparation example Construction

[0029] The preparation method of the described water glass carbon dioxide hardened molding sand that is suitable for casting alkaline high manganese steel casting material, comprises the following steps:

[0030] (1) The raw materials are prepared by pulverizing and ball milling to form a powder with a particle size greater than 40 meshes. According to the parts by weight of the formula, calcium oxide sand, forsterite sand, silica sand, zircon sand, polytrifluoroethylene Ethylene propylene, paraffin-based calcium petroleum sulfonate, and chromium oxide fibers are stirred and mixed to obtain a powder mixture;

[0031] (2) Add the powder mixture into the sand mixing device, uniformly pump the water glass solution into the sand mixing device with a liquid pump, and make the powder mixture evenly mix to make a semi-finished product;

[0032] (3) Add the semi-finished product to the sand box where the mold is placed, and tighten it;

[0033] (4) Insert a vent hole in the molding s...

Embodiment 1

[0035] A kind of sodium silicate carbon dioxide hardened molding sand suitable for casting alkaline high manganese steel casting materials, which includes the following raw materials in parts by weight: 60 parts of calcium oxide sand, 8 parts of forsterite sand, 2 parts of silica sand, zircon sand 3 parts, 5 parts of water glass solution, 1 part of polytrifluoroethylene propylene, 2 parts of paraffin-based calcium petroleum sulfonate, 0.4 part of chromium oxide fiber;

[0036] The calcium oxide content in the calcium oxide sand is 97.53%, and the particle size is 20 mesh;

[0037] The magnesium oxide content in the forsterite sand is 48.76%, and the particle size is 20 mesh;

[0038] The silicon dioxide content in the silica sand is 87.16%, the alumina is 2.69%, and the particle size is 40 mesh;

[0039] The content of zirconia in the zircon sand is 67.58%, the content of silicon oxide is 15.61%, the content of titanium oxide is 0.24%, the content of aluminum oxide is 0.13%, ...

Embodiment 2

[0049] A kind of sodium silicate carbon dioxide hardened molding sand suitable for casting alkaline high manganese steel casting materials, which includes the following raw materials in parts by weight: 70 parts of calcium oxide sand, 10 parts of forsterite sand, 3 parts of silica sand, zircon sand 5 parts, 6 parts of water glass solution, 1.6 parts of polytrifluoroethylene propylene, 3 parts of paraffin-based calcium petroleum sulfonate, 0.6 parts of chromium oxide fiber;

[0050] The calcium oxide content in the calcium oxide sand is 98.29%, and the particle size is 40 mesh;

[0051] The magnesium oxide content in the forsterite sand is 53.82%, and the particle size is 40 mesh;

[0052] The silicon dioxide content in the silica sand is 90.47%, the alumina is 5%, and the particle size is 20 mesh;

[0053] The content of zirconia in the zircon sand is 66.12%, the content of silicon oxide is 15.49%, the content of titanium oxide is 0.14%, the content of aluminum oxide is 0.21%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com