Isobutane dehydrogenation catalyst and preparation method thereof and method for preparing isobutene from isobutane dehydrogenation

A technology of dehydrogenation catalyst and isobutane, which is applied in the direction of catalyst activation/preparation, catalyst, molecular sieve catalyst, etc., can solve the problems of uneven dispersion of noble metal active components, poor catalytic activity and stability, and poor effect of removing impurities. The effect of reducing the risk of carbon deposition, high membrane surface velocity, and reducing the cost of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] This example is used to illustrate the isobutane dehydrogenation catalyst and its preparation method.

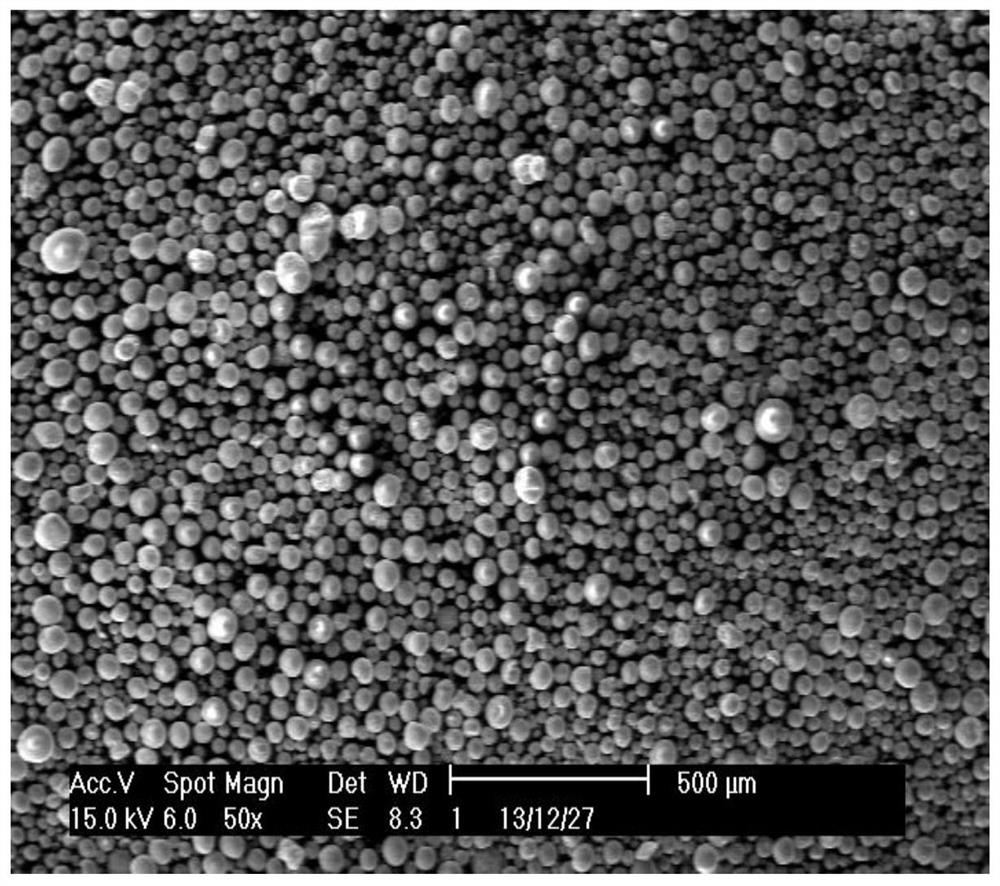

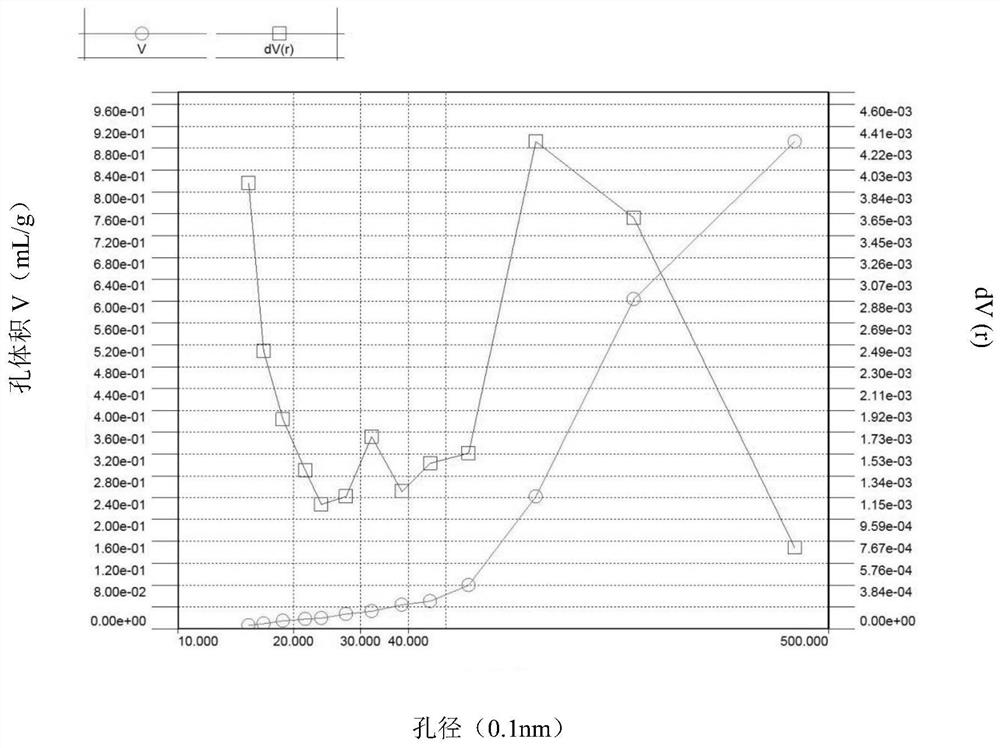

[0069] (1) Preparation of silica gel carrier

[0070] Water glass with a concentration of 15% by weight, sulfuric acid solution with a concentration of 12% by weight, n-butanol and glycerin are mixed in a weight ratio of 5:1:1:1 and contacted for 1.5 hours at 30°C. A pH adjustment of 3 for 98% by weight sulfuric acid gives the contact product A1. Pass the contact product A1 into a ceramic membrane filtration system and filter and wash with deionized water and ethanol until the content of sodium ions in the material is 0.02% by weight in terms of sodium element, and then collect the washing product B1 in the ceramic membrane filter tube, Get 30g of the washing product B1 and put it into a 100ml ball milling tank, wherein the material of the ball milling tank is polytetrafluoroethylene, the material of the grinding balls is agate, the diameter of the grinding balls is ...

Embodiment 2

[0094] This example is used to illustrate the isobutane dehydrogenation catalyst and its preparation method.

[0095] (1) Preparation of silica gel carrier

[0096]Water glass with a concentration of 15% by weight, sulfuric acid solution with a concentration of 12% by weight, n-butanol and glycerol are mixed in a weight ratio of 4:1:1:1 and contacted for 1.5h at 40°C. A pH adjustment of 2 for 98% by weight sulfuric acid gives contact product A2. Pass the contact product A2 into a ceramic membrane filtration system and filter and wash it with deionized water until the content of sodium ions in the material is 0.01% by weight in terms of sodium element, then collect the washing product B2 in the ceramic membrane filter tube and take 30g The washed product B2 is put into a 100ml ball mill jar, wherein the ball mill jar is made of polytetrafluoroethylene, the ball is made of agate, the diameter of the ball is 3mm, the number is 1, and the rotation speed is 400r / min. Close the ba...

Embodiment 3

[0105] This example is used to illustrate the isobutane dehydrogenation catalyst and its preparation method.

[0106] (1) Preparation of silica gel carrier

[0107] Water glass with a concentration of 15% by weight, sulfuric acid solution with a concentration of 12% by weight, n-butanol and glycerol are mixed in a weight ratio of 6:1:1:1 and contacted for 1.5 hours at 20°C. Adjustment of pH to 4 for 98% by weight sulfuric acid gives contact product A3. Pass the contact product A3 into a ceramic membrane filtration system and filter and wash with deionized water and ethanol until the content of sodium ions in the material is 0.03% by weight in terms of sodium element, and then collect the washing product B3 in the ceramic membrane filter tube, Get 30g of said washing product B3 and put it into a 100ml ball milling tank, wherein the material of the ball milling tank is polytetrafluoroethylene, the material of the grinding balls is agate, the diameter of the grinding balls is 3m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com