Thermal dye sublimation transfer paper coating, thermal dye sublimation transfer paper and preparation method thereof

A transfer paper and thermal sublimation technology, applied in the field of papermaking, can solve the problems that the drying speed, ink transfer rate and pattern clarity are difficult to meet the quality requirements of thermal sublimation transfer paper, so as to improve the ink transfer rate and printing clarity, The effect of accelerating the drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

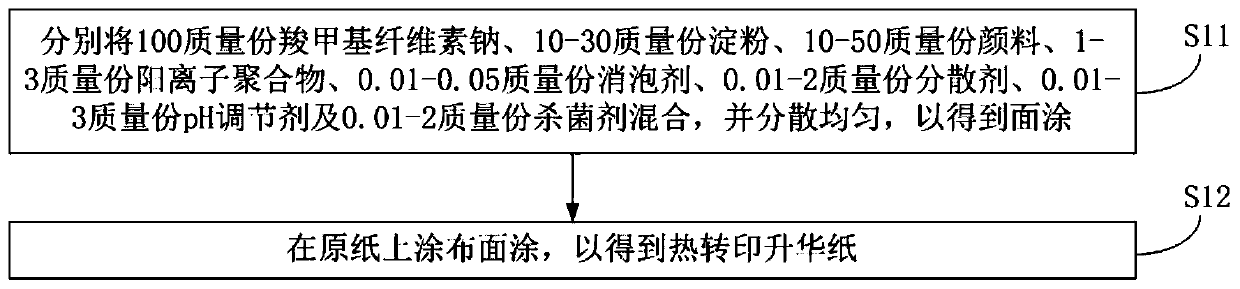

[0031] see figure 1 , figure 1 It is a schematic flow diagram of an embodiment of the preparation method of the sublimation transfer paper of the present application, and the preparation method includes:

[0032]Step S11: 100 parts by mass of sodium carboxymethylcellulose, 10-30 parts by mass of starch, 10-50 parts by mass of pigment, 1-3 parts by mass of cationic polymer, 0.01-0.05 parts by mass of defoamer, 0.01-2 parts by mass of Mix parts by mass of dispersant, 0.01-3 parts by mass of pH regulator and 0.01-2 parts by mass of bactericide, and disperse evenly to obtain top coating;

[0033] Wherein, starch is ungelatinized starch;

[0034] Step S12: coating a topcoat on the base paper to obtain thermal transfer sublimation paper.

[0035] Wherein, starch is added in the form of dispersion liquid of starch in cold water. It should be pointed out that the "cold water" here is not limited to water with a very low temperature, as long as the temperature can make the starch i...

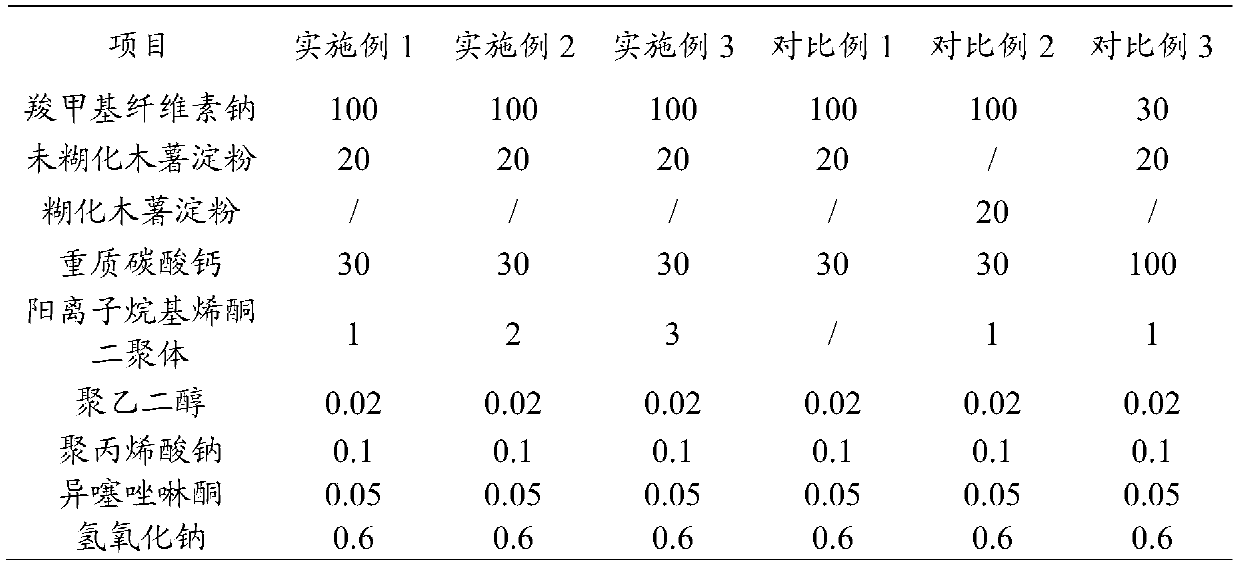

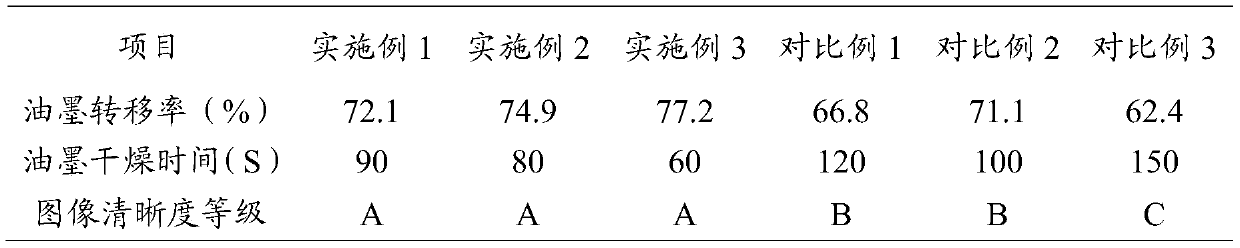

Embodiment 1

[0041] 100 parts of sodium carboxymethylcellulose (degree of substitution 0.8), 20 parts of ungelatinized tapioca starch, 30 parts of heavy calcium carbonate, 1 part of cationic alkylketene dimer, 0.02 parts of polyethylene glycol, 0.1 part of sodium polyacrylate, 0.05 part of isothiazolinone, and 0.6 part of sodium hydroxide are mixed together according to the order of the formula in Table 1, and after high-speed dispersion, a uniformly dispersed coating is obtained;

[0042] The above coating is 42g / m in gram weight 2 The base paper is coated on one side, and the coating amount is 4g / m 2 ; After the coating is completed, drying treatment is carried out to obtain sublimation transfer paper.

Embodiment 2

[0044] 100 parts of sodium carboxymethylcellulose (degree of substitution 0.8), 20 parts of ungelatinized tapioca starch, 30 parts of heavy calcium carbonate, 2 parts of cationic alkylketene dimer, 0.02 parts of polyethylene glycol, 0.1 part of sodium polyacrylate, 0.05 part of isothiazolinone, and 0.6 part of sodium hydroxide are mixed together according to the order of the formula in Table 1, and after high-speed dispersion, a uniformly dispersed coating is obtained;

[0045] The above coating is 42g / m in gram weight 2 The base paper is coated on one side, and the coating amount is 4g / m 2 ; After the coating is completed, drying treatment is carried out to obtain sublimation transfer paper.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com