Mildew-proof and moisture-proof optical film and preparation method thereof

An optical film, anti-mildew technology, applied in optics, optical components, ion implantation and plating, etc., can solve the problem of lack of effective solutions, and achieve the improvement of moisture-proof and mildew-proof performance, compactness, and compactness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The moisture-proof and mildew-proof optical film involved in the present invention is realized on a Leybold SYRUSpro1110 vacuum coating machine; the equipment is equipped with an APSII plasma source, an electron beam evaporation system, and an IC5 film thickness monitor.

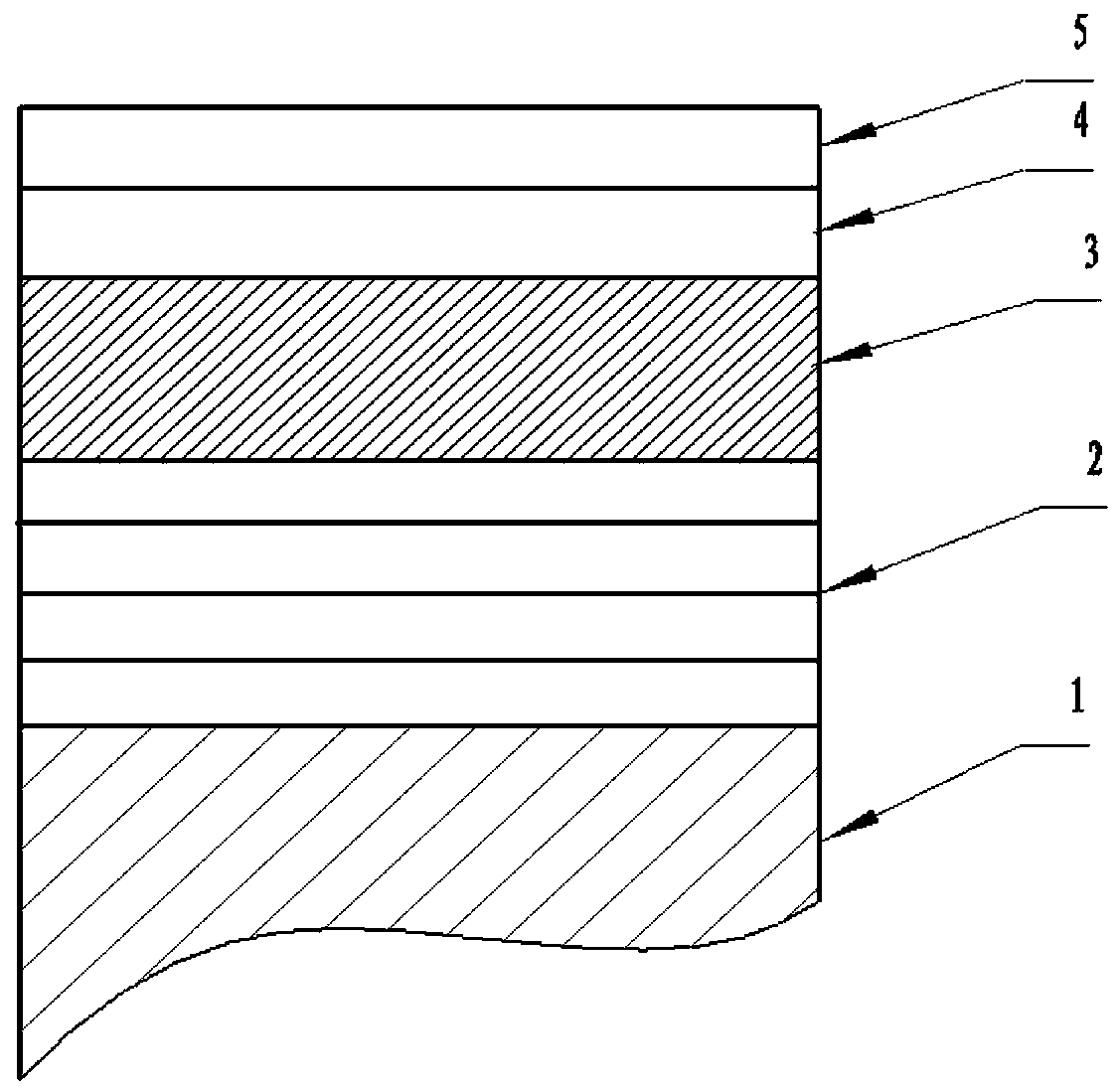

[0038] refer to Figure 1 to Figure 3 As shown, the present invention discloses a moisture-proof and mildew-proof optical film with high transmittance, including a substrate 1, a high-density anti-reflection film system main body 2 and a hard wear-resistant protective layer 3 evaporated on the substrate 1 in sequence , the first hydrophobic film layer 4 and the second hydrophobic film layer 5; the substrate 1 is glass, sapphire, zinc sulfide or silicon wafer of the same material as the optical window, so the substrate 1 of the present invention can be Lay on the optical window and form an integral body with it, and the optical window can also be used as the substrate 1 to evaporate other film layers seq...

Embodiment 2

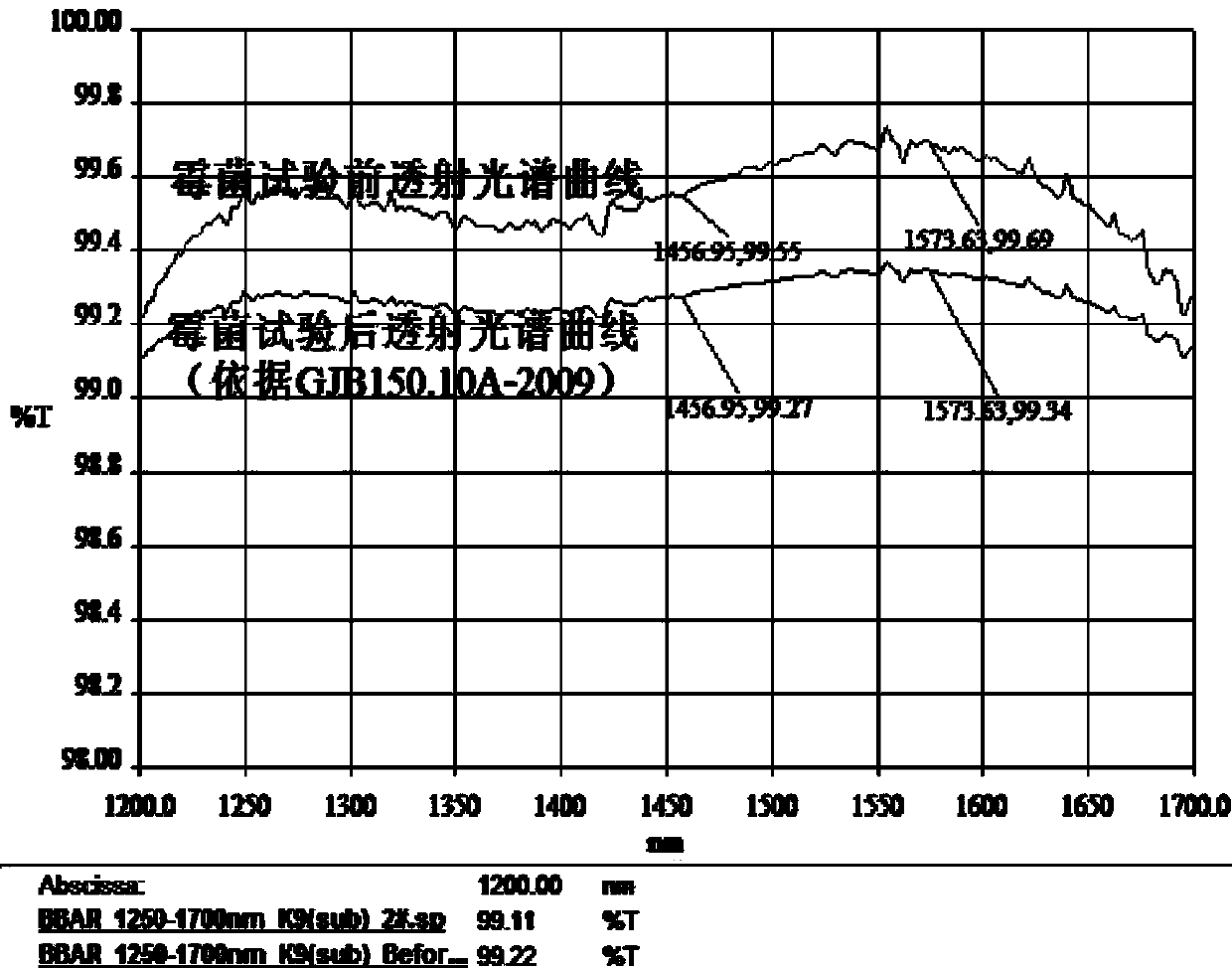

[0044] A high-efficiency anti-reflection film with moisture-proof and mildew-proof functions coated on a K9 glass light window, the size . The technical requirements are as follows: , incident angle 0-30 0 . The coating sample passed the high and low temperature, constant humidity, adhesion and severe friction tests specified in GJB2485-1995 at one time. At the same time, it can also withstand the mold test specified in GJB150.10A-2009.

[0045] First of all, according to the above technical requirements, the optimal design of the film structure is carried out, and the results are as follows:

[0046]

[0047] Among them, the material of the hard wear-resistant protective layer 3 is selected as SiO 2 , a-f are the physical thickness of the film layer, respectively, M1 and M2 are both fluorine-silicon-based organic hydrophobic film layers, and their physical thickness is 6.0nm. The physical thickness of other film layers is as follows:

[0048] a-70.25nm; b-82.66nm;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com