Method for preparing furfural through steam-assisted fixed bed pyrolysis of wood fiber biomass

A technology for lignocellulosic and biomass, which is applied in the field of steam-assisted fixed bed pyrolysis of lignocellulosic biomass to prepare furfural, can solve the problems of difficult recovery of catalysts, difficult to realize industrialization, poor stability of catalysts, etc., so as to avoid corrosion of catalysts and equipment, improve Process safety, achieving continuous effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Weigh 20 g of crushed corncobs, 150 g of water and 5 mmol of H 2 SO 4 Add to the beaker, stir and dry; the loaded H 2 SO 4 Add corncobs into the fixed-bed reactor; then add deionized water to the steam generating device, and raise the temperature to 150°C; raise the temperature of the fixed-bed reactor to 230°C; open the outlet valve of the steam generating device, and adjust the steam flow rate. Higher than 5g / min; steam passes through the fixed bed reactor bed from bottom to top; the continuous pyrolysis and extraction time is 2h, the pyrolysis product is removed from the fixed bed reactor, and finally the steam is condensed to obtain furfural-rich The aqueous phase was finally extracted with ethyl acetate to obtain the furfural product. The product yield is shown in Table 1, and the furfural product yield was 8.1 wt%.

Embodiment 2

[0033] Weigh 20 g of crushed corncobs, 150 g of water and 5 mmol of AlCl 3 Add to the beaker, stir and dry; the loaded AlCl 3 Add corncobs into the fixed-bed reactor; then add deionized water to the steam generating device, and raise the temperature to 150°C; raise the temperature of the fixed-bed reactor to 230°C; open the outlet valve of the steam generating device, and adjust the steam flow rate. Higher than 5g / min; steam passes through the fixed bed reactor bed from bottom to top; the continuous pyrolysis and extraction time is 2h, the pyrolysis product is removed from the fixed bed reactor, and finally the steam is condensed to obtain furfural-rich The aqueous phase, and finally extract the furfural product through ethyl acetate extraction, the product yield is shown in Table 1, and the furfural product yield is 10.5wt%.

Embodiment 3

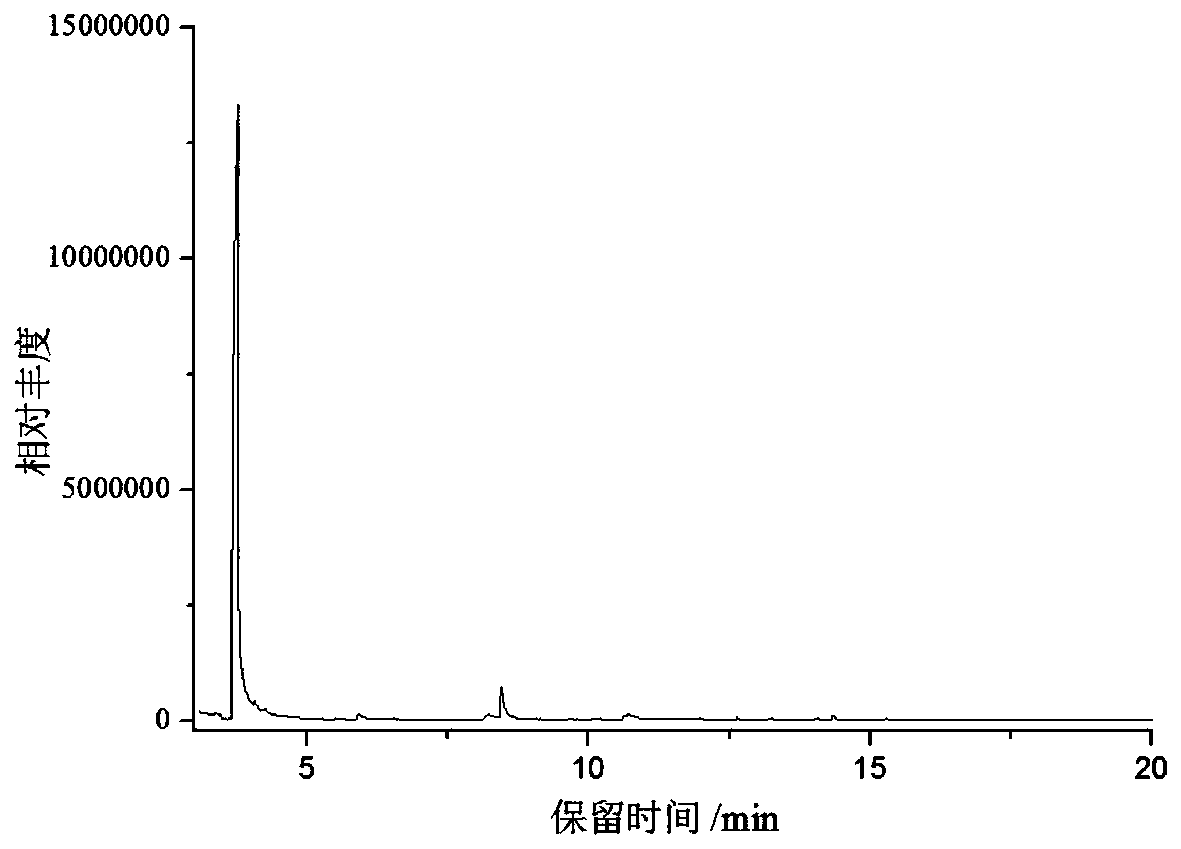

[0035] Weigh 20g of crushed corn cob, 150g of water and 5mmol of Al 2 (SO 4 ) 3 Add to the beaker, stir and dry; the loaded Al 2 (SO 4 ) 3Add corncobs into the fixed-bed reactor; then add deionized water to the steam generating device, and raise the temperature to 150°C; raise the temperature of the fixed-bed reactor to 230°C; open the outlet valve of the steam generating device, and adjust the steam flow rate. Higher than 10g / min; the steam passes through the bed of the fixed bed reactor from bottom to top, and the pyrolysis products are removed from the fixed bed reactor, and finally the steam is condensed to obtain a furfural-rich aqueous phase, which is finally extracted with ethyl acetate The furfural product was obtained, and the yield of the product was shown in Table 1. The yield of the furfural product was 15.7 wt%. The time for continuous pyrolysis and extraction was 2 hours. The furfural product obtained by ethyl acetate extraction was analyzed by GC-MS total i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com