Beneficiation method for recovering tin and silver from skarn type low-grade tin tailings

A beneficiation method and low-grade technology, applied in chemical instruments and methods, flotation, magnetic separation, etc., can solve the problems of high cost, low efficiency of fine-grained cassiterite, poor rationality, etc., and achieve low production cost, flotation agent The effect of low dosage and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

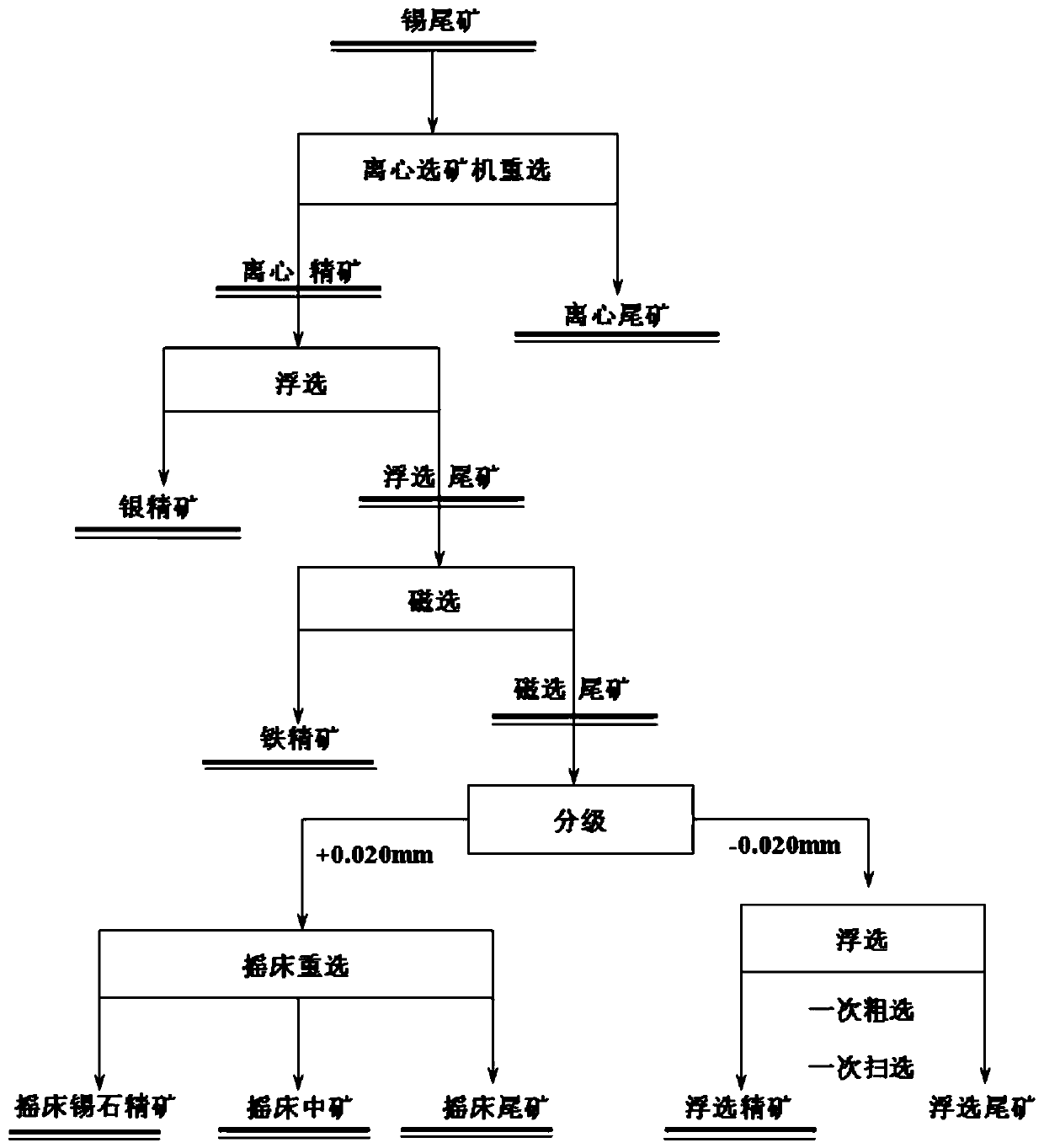

[0052] This embodiment provides a kind of beneficiation method for reclaiming tin and silver in skarn type low-grade tin tailings, such as figure 1 , the specific process is as follows.

[0053]The tin content of a certain tin tailings is 0.49%, the silver grade is 25.30g / t, and the -0.074mm ore sample is taken by screening, accounting for 100% of the ore. After gravity separation in a centrifuge, centrifugal concentrate and centrifugal tailings are obtained. The yield of centrifugal tailings is 67.74%. , tin grade 0.19%, tin recovery rate 26.27%. Add water to the centrifugal concentrate to adjust the slurry to a concentration of 30%. According to each ton of ore, add 500 grams of sodium silicate, 80 grams of O-isopropyl-N-ethylthiocarbamate and 40 grams of methyl amyl alcohol Roughing, adding 40 grams of O-isopropyl-N-ethyl thiocarbamate and 20 grams of methyl amyl alcohol to the roughing tailings for scavenging, the roughing concentrate and the scavenging concentrate are co...

Embodiment 2

[0055] This embodiment provides a kind of beneficiation method for reclaiming tin and silver in skarn type low-grade tin tailings, such as figure 1 , the specific process is as follows.

[0056] The tin content of a certain tin tailings is 0.41%, the silver grade is 21.22g / t, and the -0.074mm ore sample is screened to account for 100%. After gravity separation by a centrifuge, centrifugal concentrate and centrifugal tailings are obtained. The yield of centrifugal tailings is 69.70%. , tin grade 0.14%, tin recovery rate 23.80%. Add water to the centrifugal concentrate to adjust the slurry to a concentration of 28%, and add 1,000 grams of sodium silicate, 100 grams of 1,3-dimethylbutyl xanthate and 40 grams of methyl amyl alcohol for roughing in turn according to each ton of ore. Add 50 grams of 1,3-dimethylbutyl xanthate sodium and 20 grams of methyl amyl alcohol to the roughing tailings for scavenging, the roughing concentrate and the scavenging concentrate are combined into ...

Embodiment 3

[0058] This embodiment provides a kind of beneficiation method for reclaiming tin and silver in skarn type low-grade tin tailings, such as figure 1 , the specific process is as follows.

[0059] The tin content of a certain tin tailings is 0.54%, the silver grade is 34.79g / t, and the -0.074mm ore samples are taken by screening, accounting for 100% of the ore. After gravity separation by a centrifuge, centrifugal concentrate and centrifugal tailings are obtained. The yield of centrifugal tailings is 69.31%. , tin grade 0.21%, tin recovery rate 26.95%. Add water to the centrifugal concentrate to adjust the slurry to a concentration of 32%. According to each ton of ore, add 2000 grams of sodium silicate, 90 grams of dibutyl ammonium dithiophosphate and 30 grams of methyl isobutyl carbitol for roughing. 45 grams of dibutyl ammonium dithiophosphate and 15 grams of methyl isobutyl carbitol were added to the tailings for scavenging, and the roughing concentrate and scavenging concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com