Control modulation method for high-power direct-drive permanent magnet synchronous motor

A technology of permanent magnet synchronous motor and modulation method, which is applied in the direction of motor control, motor generator control, AC motor control, etc., and can solve the problem that the control system cannot be satisfied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

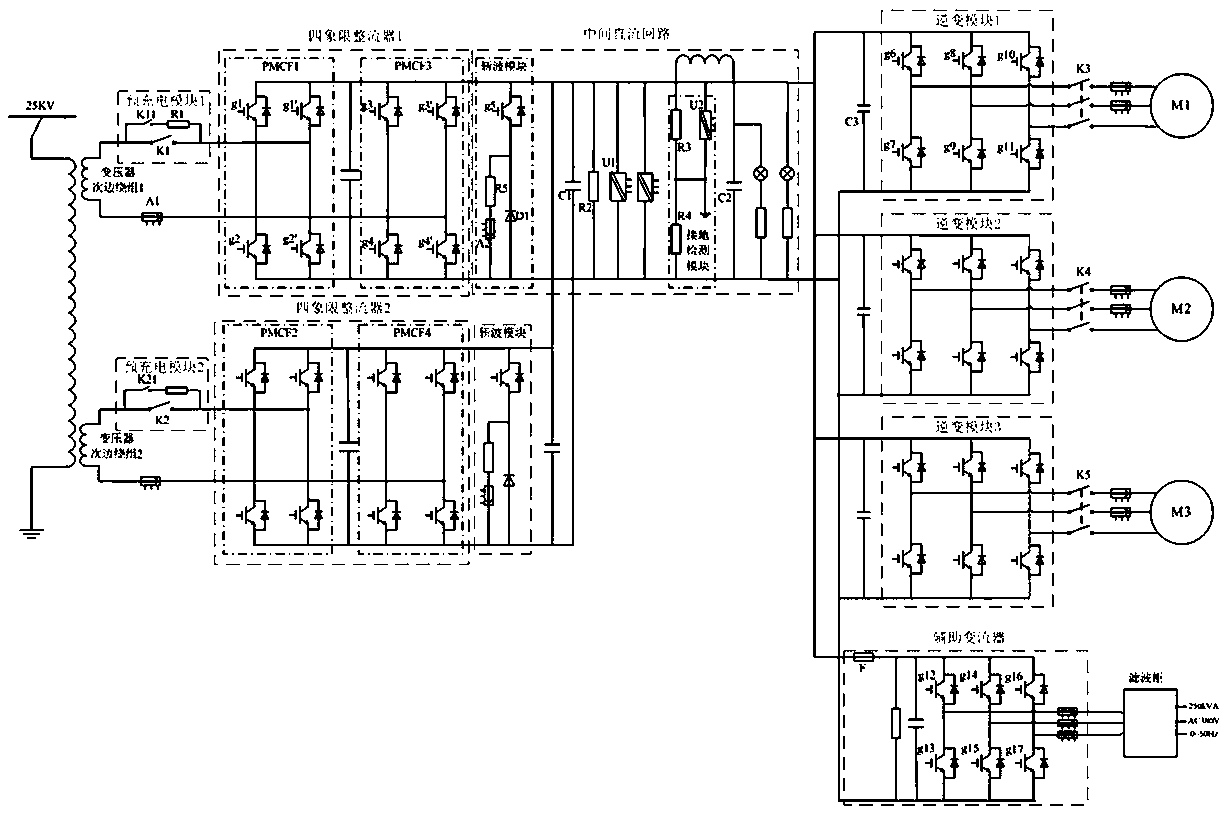

[0043] Direct drive permanent magnet traction electric drive system

[0044] Such as figure 1 As shown, the main circuit topology of the direct-drive permanent magnet traction electric drive system adopts the AC-DC connection mode. The input end of the traction converter is connected with the secondary traction winding of the main transformer, and is opened / closed through a contactor. The outputs of two four-quadrant rectifiers are connected in parallel and share the intermediate DC circuit. The intermediate DC circuit is equipped with supporting capacitors, secondary filter capacitors (the secondary filter inductors are integrated in the traction transformer), ground detection and protection devices, etc. The shared intermediate DC circuit supplies power to three traction inverters and one auxiliary inverter. The traction inverter provides three-phase variable frequency and variable voltage AC power to the high-power direct-drive permanent magnet synchronous motor, and one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com