Lithium metal negative electrode material, preparation method and application thereof

A lithium metal anode, slurry technology, applied in electrode manufacturing, battery electrodes, lithium batteries, etc., can solve the problems of high reactivity of lithium and electrolyte, non-uniformity of deposition/dissolution, low electrode potential, etc. Effects of conduction and migration, controllable coating uniformity, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The embodiment of the present invention provides a preparation method of a lithium metal negative electrode material, which includes:

[0041] S1, preparing a high molecular polymer; wherein, the high molecular polymer is formed by free radical polymerization of monomer A and monomer B, wherein the monomer A is selected from acrylonitrile or its derivatives; the monomer Body B is selected from polyethylene glycol acrylates.

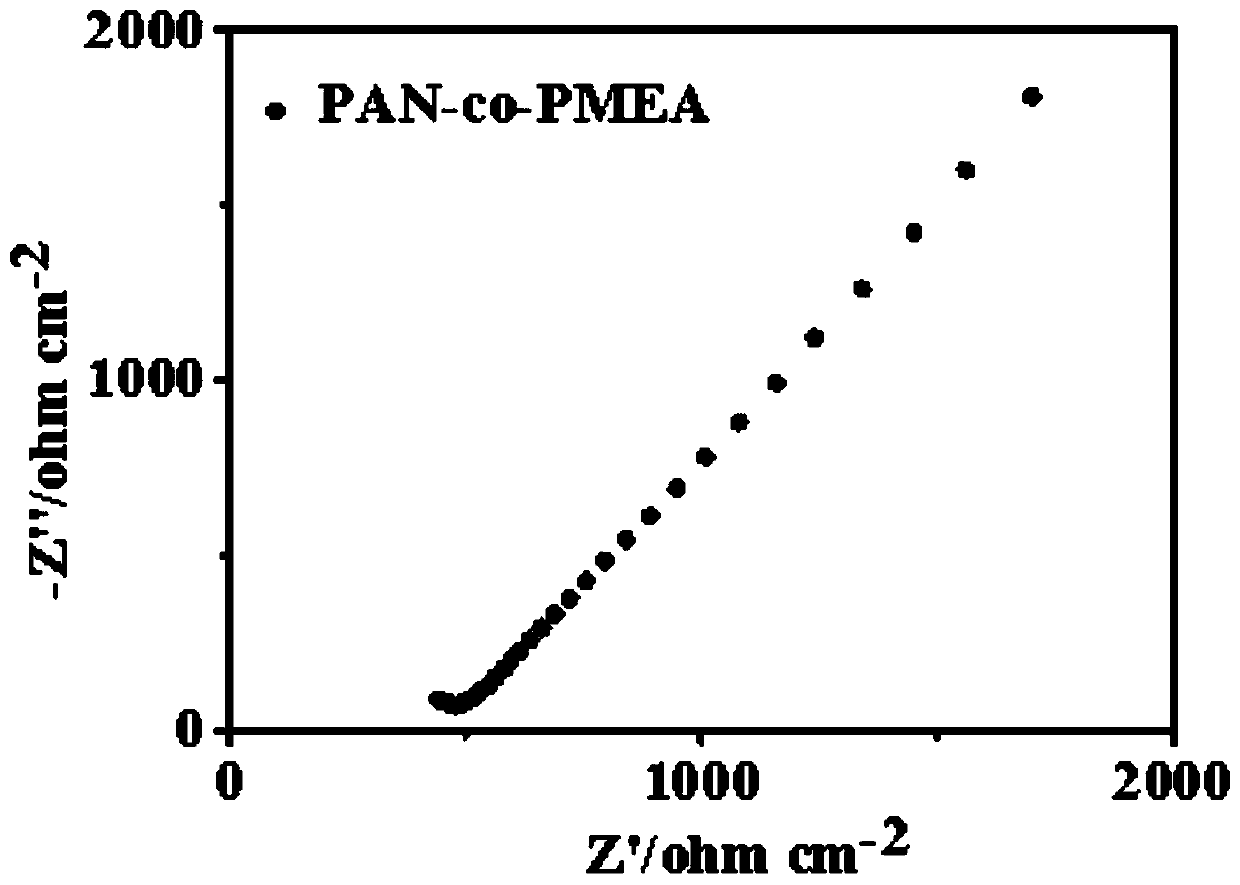

[0042] Acrylonitrile or its derivatives and polyethylene glycol acrylate of the present invention are used as comonomers of high molecular polymers, wherein acrylonitrile or its derivatives are conducive to the dissociation of lithium salts and high pressure resistance, ensuring the stability of the battery Circular and safe. Since acrylonitrile polymers do not have the ability to conduct ions, while polyethylene glycol acrylate polymers are rich in carbonyl oxygen and ether oxygen groups, which are conducive to the conduction and migration of lit...

Embodiment 1

[0063] This embodiment provides a method for preparing a lithium metal negative electrode material, comprising the following steps:

[0064] S1, under the protection of argon, disperse acrylonitrile and polyethylene glycol methyl methacrylate in water, add initiator KPS, and react at 70°C for 12h; wherein, the acrylonitrile and polyethylene glycol methacrylic acid The mol ratio of methyl ester is 1:1, and the mass ratio of described thermal initiator and described monomer B is 0.001:1;

[0065] S2, dissolving the high molecular polymer in N-methylpyrrolidone to obtain a 10wt% slurry;

[0066] S3, coating the slurry with a thickness of 5 μm on the copper foil of the current collector, and transferring to 60° C. for vacuum drying for 6 hours to obtain a modified current collector;

[0067] S4, deposit lithium metal on the modified current collector, the deposition capacity is 1mAh / cm 2 , the current density is 0.2mA / cm 2 , to obtain a lithium metal negative electrode material...

Embodiment 2

[0069] This embodiment provides a method for preparing a lithium metal negative electrode material, comprising the following steps:

[0070] S1, under the protection of argon, disperse acrylonitrile and polyethylene glycol methyl methacrylate in water, add initiator KPS, and react at 70°C for 12h; wherein, the acrylonitrile and polyethylene glycol methacrylic acid The mol ratio of methyl ester is 1:1, and the mass ratio of described thermal initiator and described monomer B is 0.001:1;

[0071] S2, dissolving the high molecular polymer in N-methylpyrrolidone to obtain a 10wt% slurry;

[0072] S3, coating the slurry with a thickness of 5 μm on the copper foil of the current collector, and transferring to 60° C. for vacuum drying for 6 hours to obtain a modified current collector;

[0073] S4, deposit lithium metal on the modified current collector, the deposition capacity is 0.5mAh / cm 2 , the current density is 0.5mA / cm 2 , to obtain a lithium metal negative electrode materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com