A preparation method of an ordered ferroelectric topological domain structure array

A topological domain and ferroelectric technology, applied in circuits, electrical components, electrical solid devices, etc., can solve the problems of harsh formation conditions, low density of a single topological domain, and difficulty in integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

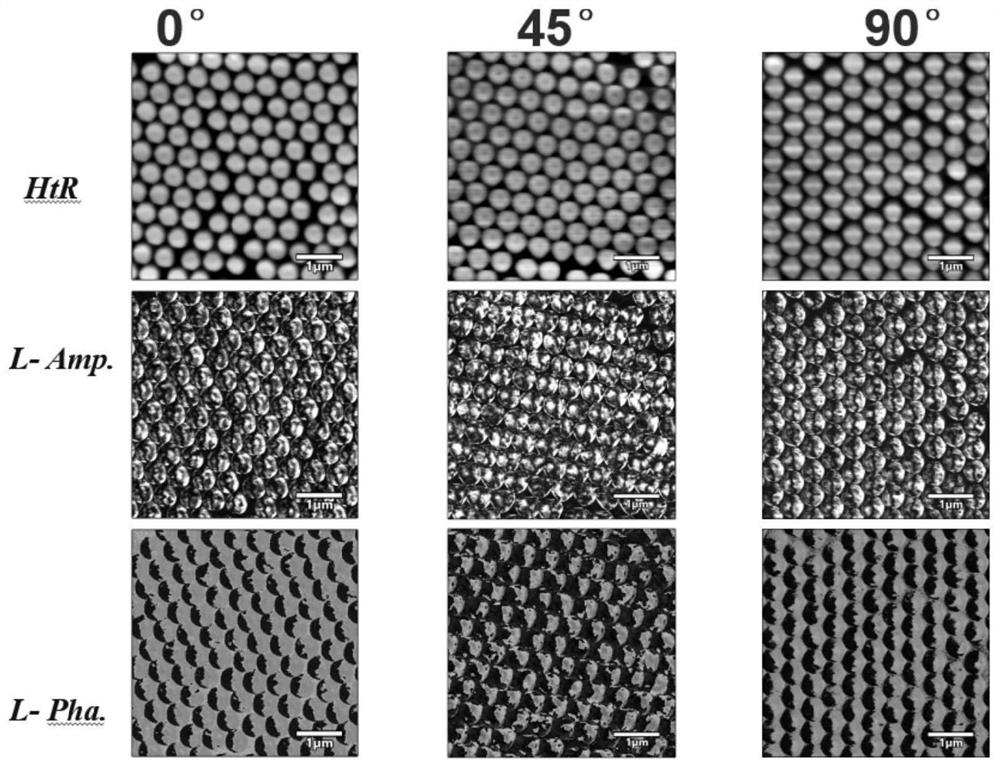

[0034] The preparation method of the ordered ferroelectric topological domain structure array of this embodiment comprises the following steps:

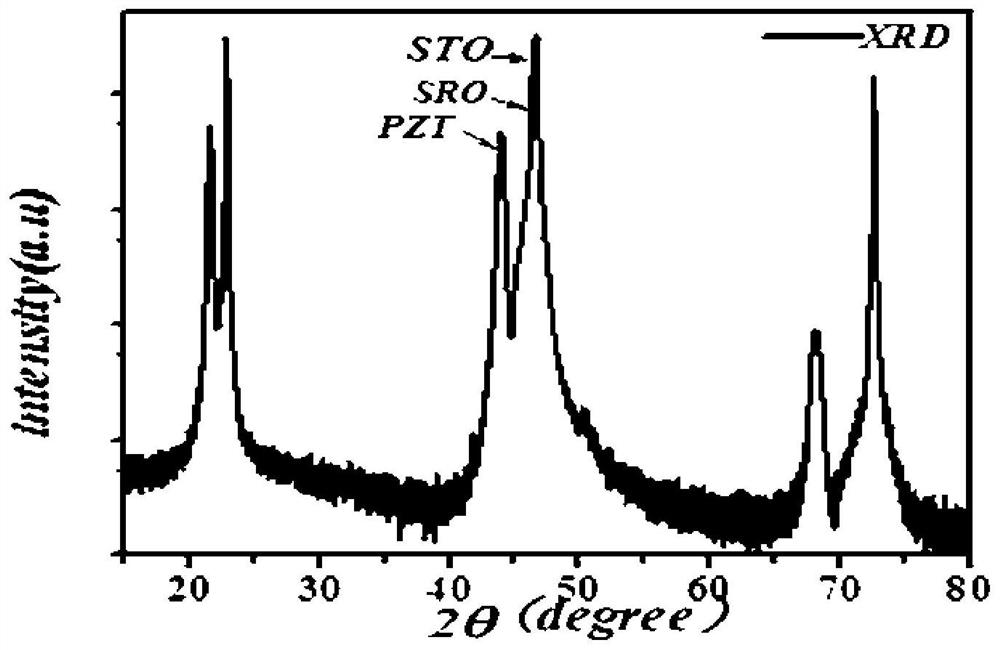

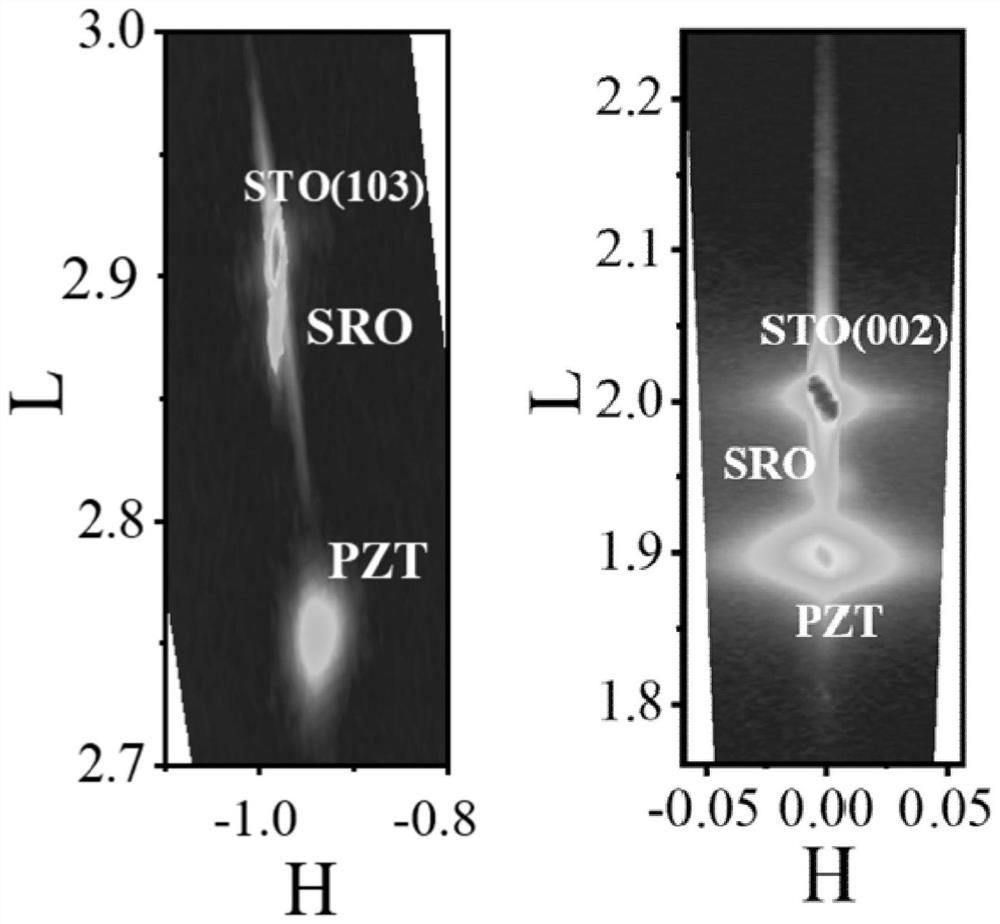

[0035] S1: Preparation of rhombohedral phase PZT thin films by pulsed laser deposition: Selecting (001) orientation of SrTiO 3 (STO) single crystal substrate on which 40 nm thick SrRuO was deposited by laser pulse deposition 3 (SRO) film is used as the bottom electrode, and the preparation parameters of the pulsed laser deposition method are as follows:

[0036] Energy (mJ / cm 3 )

Pulse frequency (Hz) temperature(℃) Oxygen pressure (Pa) 56 5 680 15

[0037] S2: Select the PZT target material with Zr:Ti=7:3, and deposit a PZT film with a thickness of 80nm on the STO substrate deposited with a layer of SRO film by the pulse laser deposition method. The preparation parameters of the pulse laser deposition method are as follows:

[0038] Energy (mJ / cm 3 )

Pulse frequency (Hz) temperature(...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com