Capacitive tomography sensor applied to two-phase flow phase distribution measurement of low-temperature fluid

A technology of capacitance tomography and low-temperature fluid, which is applied in the direction of material capacitance, etc., can solve problems such as heat leakage in low-temperature fluid pipelines, high sensitivity to flow pattern changes, and low-temperature fluid leakage, so as to avoid the intrusion of impurities, avoid capacitance drift, Avoid the effect of heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing.

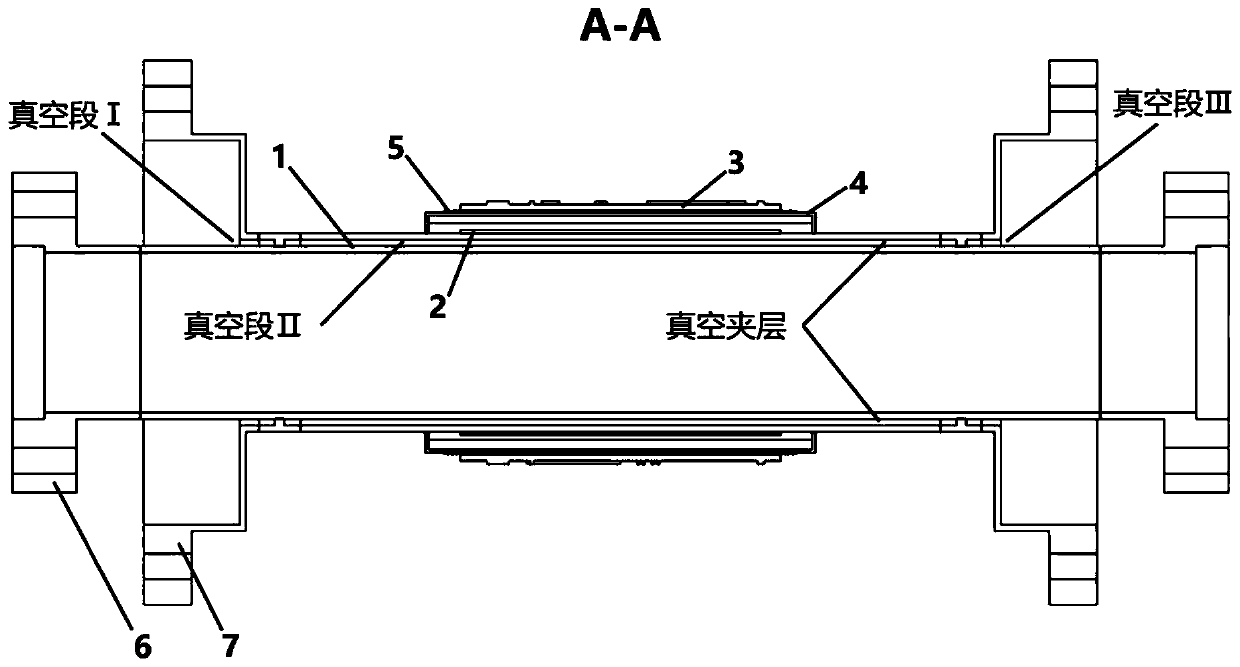

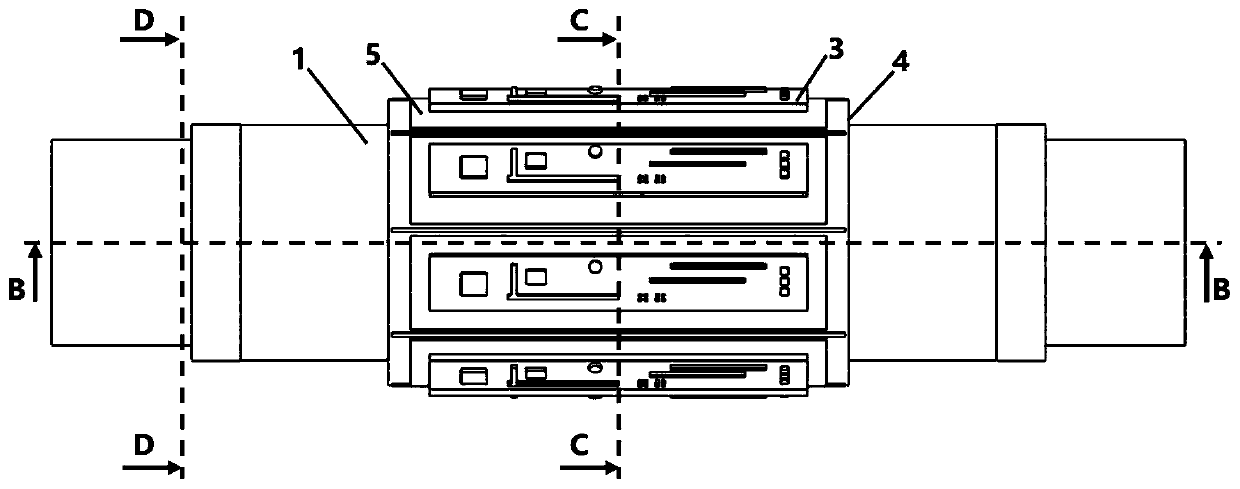

[0033] Such as Figure 1-9 As shown, in a specific embodiment of the present invention, the electrical capacitance tomography sensor applied to the measurement of the phase distribution of the two-phase flow of cryogenic fluid includes a vacuum jacketed insulating pipeline 1, an electrode sheet 2, a capacitance acquisition circuit board 3, and a shielding cover 4 , insulating pad 5, fluid pipe flange 6 and vacuum cover flange 7. Vacuum jacketed insulating pipe 1 is a circular tubular pipe with a vacuum interlayer at both ends. The inner insulation tube of the vacuum interlayer forms the inner pipeline, and the outer insulation cylinder of the vacuum interlayer forms the outer pipeline; The end is connected to the flange of the vacuum cover; the electrode piece 2 is pasted on the outside of the outer pipe of the vacuum jacket insulation pipe 1, and is evenly distributed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com