Rhenium disulfide nanosheet used for hydrogen evolution reaction, and preparation method and applications thereof

A technology for rhenium disulfide and hydrogen evolution reaction, which is applied in the field of nanomaterials and can solve the problems of non-conductivity of substrates and limited applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1. Preparation:

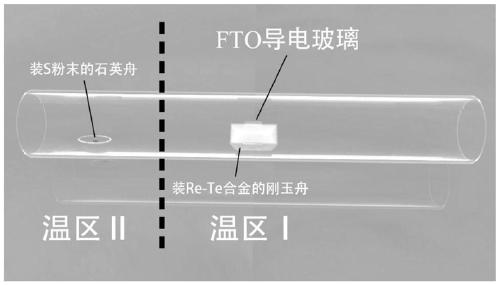

[0039] (1) Weigh 50mg of Re and 200mg of Te into a corundum boat and mix evenly, place in temperature zone Ⅰ.

[0040] (2) Weigh 0.6g of sulfur powder into a quartz boat, place it at the upstream end of the CVD furnace and install a heating belt at the position of the sulfur powder to control the temperature of sulfur alone, and the temperature control area is temperature zone II.

[0041] (3) Place the cleaned FTO conductive glass face down on the corundum boat.

[0042] (4) 200 sccm high-purity argon gas was introduced for 4 hours to fully replace the air in the CVD furnace tube, and then the flow rate of the carrier gas was adjusted to 50 sccm.

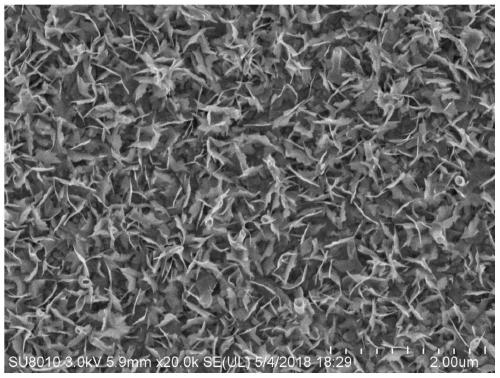

[0043] (5) CVD furnace temperature zone Ⅰ is heated to 475 ℃ at a rate of 15 ℃ / min, and the temperature is kept constant for 45 minutes. 150°C, constant temperature for 45min, then naturally cooled to room temperature, and the reaction was completed, and vertically aligned rhenium disulfide nanosheets wer...

Embodiment 2

[0046] 1. Preparation:

[0047] (1) Weigh 50mg of Re and 200mg of Te into a corundum boat and mix evenly, place in temperature zone Ⅰ.

[0048] (2) Weigh 0.6g of sulfur powder into a quartz boat, place it at the upstream end of the CVD furnace and install a heating belt at the position of the sulfur powder to control the temperature of sulfur alone, and the temperature control area is temperature zone II.

[0049] (3) Place the cleaned FTO conductive glass face down on the corundum boat.

[0050] (4) 200 sccm high-purity argon gas was introduced for 4 hours to fully replace the air in the CVD furnace tube, and then the flow rate of the carrier gas was adjusted to 50 sccm.

[0051] (5) CVD furnace temperature zone Ⅰ is heated to 500 ℃ at a rate of 10 ℃ / min, and the temperature is kept constant for 30 minutes. 170°C, constant temperature for 30min, then naturally cooled to room temperature, and the reaction was completed, and vertically aligned rhenium disulfide nanosheets wer...

Embodiment 3

[0054] 1. Preparation:

[0055] (1) Weigh 50mg of Re and 200mg of Te into a corundum boat and mix evenly, place in temperature zone Ⅰ.

[0056] (2) Weigh 0.6g of sulfur powder into a quartz boat, place it at the upstream end of the CVD furnace and install a heating belt at the position of the sulfur powder to control the temperature of sulfur alone, and the temperature control area is temperature zone II.

[0057] (3) Place the cleaned FTO conductive glass face down on the corundum boat.

[0058] (4) 200 sccm high-purity argon gas was introduced for 4 hours to fully replace the air in the CVD furnace tube, and then the flow rate of the carrier gas was adjusted to 50 sccm.

[0059] (5) CVD furnace temperature zone Ⅰ is heated to 450 ℃ at a rate of 20 ℃ / min, and the temperature is kept constant for 45 minutes. 120°C, constant temperature for 45min, then naturally cooled to room temperature, the reaction was completed, and anisotropically grown on the FTO substrate to prepare v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com