Preparation method of 5-hydroxytryptophan sustained-release tablets

A technology of hydroxytryptophan and controlled-release tablets, which can be applied in pharmaceutical formulations, medical preparations with non-active ingredients, and medical preparations containing active ingredients, etc., can solve the problem of high cost of 5-hydroxytryptophan matrix sustained-release tablets , to achieve the effects of good production controllability, relieving depression and increasing wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

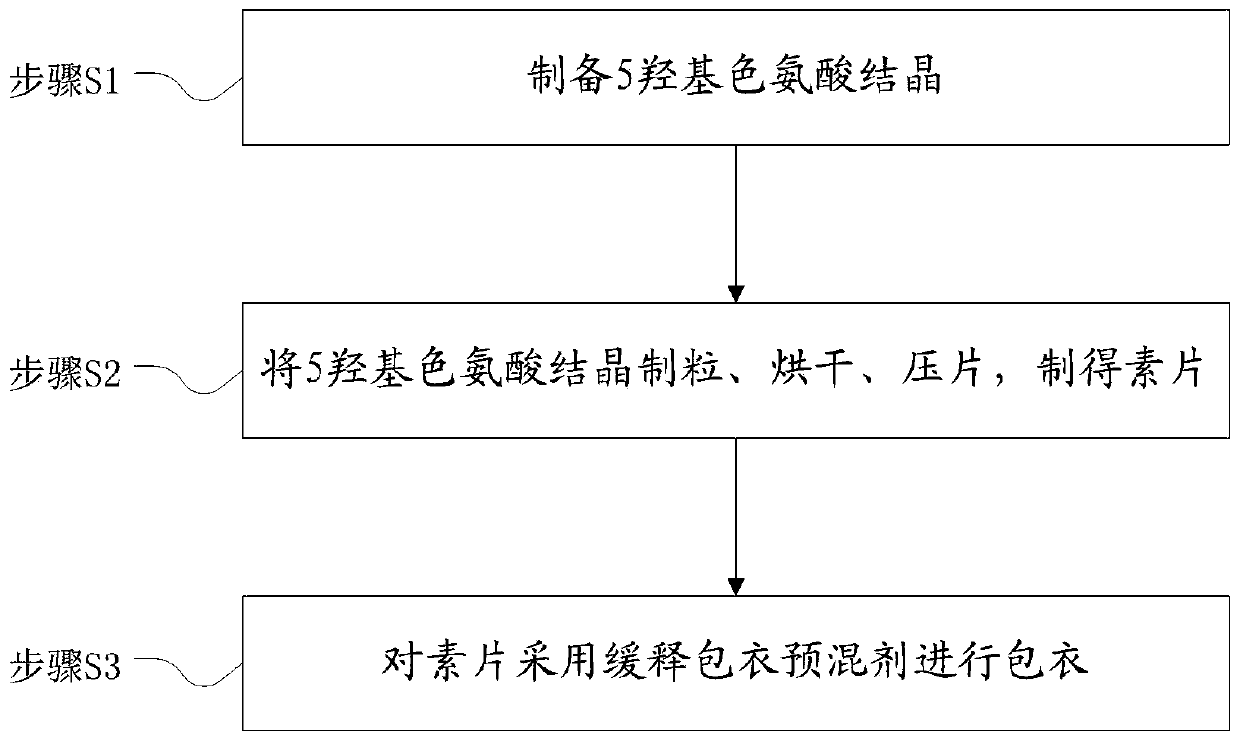

[0032] The preparation method of 5-hydroxytryptophan sustained and controlled release tablets, see the flow chart figure 1 , including the following steps:

[0033] Step S1, preparing 5-hydroxytryptophan crystals;

[0034] Step S2, granulating, drying, and tableting 5-hydroxytryptophan crystals to obtain a plain tablet; the process of preparing the plain tablet can use the preparation method in the prior art;

[0035] Step S3, coating the plain tablet with a slow-release coating premix, and adjusting the dosage of the slow-release coating premix according to the release rate to achieve the expected release rate;

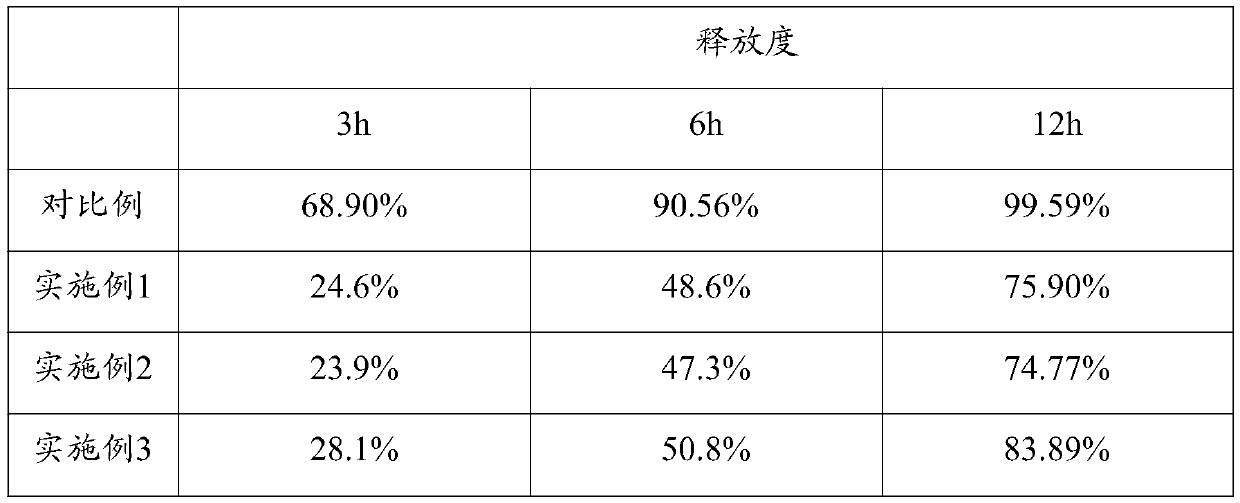

[0036] Wherein the sustained-release coating premix comprises, by weight: 30 parts of ethyl cellulose, 2 parts of silicon dioxide and 1 part of walnut oil.

[0037] During the coating process, the weight ratio of the final coating to the plain tablet is controlled between 1:25 and 1:12, and a batch of several 5-hydroxytryptophan sustained-release tablets are prepar...

Embodiment 2

[0039] The preparation method of 5-hydroxytryptophan sustained and controlled release tablet comprises the following steps:

[0040] Step S1, preparing 5-hydroxytryptophan crystals;

[0041] Step S2, granulating 5-hydroxytryptophan crystals, drying, and tableting to obtain plain tablets;

[0042] Step S3, coating the plain tablet with a slow-release coating premix, and adjusting the dosage of the slow-release coating premix according to the release rate to achieve the expected release rate;

[0043] The sustained-release coating premix comprises, by weight, 70 parts of ethyl cellulose, 8 parts of titanium dioxide, and 6 parts of a mixture of rapeseed oil and soybean oil.

[0044] During the coating process, the weight ratio of the final coating to the plain tablet is controlled between 1:25 and 1:12, and a batch of several 5-hydroxytryptophan sustained-release tablets are prepared.

Embodiment 3

[0046] The preparation method of 5-hydroxytryptophan sustained and controlled release tablet comprises the following steps:

[0047] Step S1, preparing 5-hydroxytryptophan crystals;

[0048] Step S2, granulating 5-hydroxytryptophan crystals, drying, and tableting to obtain plain tablets;

[0049] Step S3, coating the plain tablet with a slow-release coating premix, and adjusting the dosage of the slow-release coating premix according to the release rate to achieve the expected release rate;

[0050] The slow-release coating premix comprises, by weight, 50 parts of ethyl cellulose, 5 parts of plant carbon black, a mixture of yellow iron oxide and 4 parts of sesame oil.

[0051] During the coating process, the weight ratio of the final coating to the plain tablet is controlled between 1:25 and 1:12, and a batch of several 5-hydroxytryptophan sustained-release tablets are prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com