Method for detecting furfural content of transformer oil

A technology for transformer oil and furfural is applied in the field of detecting furfural content in transformer oil, which can solve the problems of small insulating oil, the concentration of dissolved furfural cannot meet the requirements of industrial indicators, interference, etc. Mann high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: prepare standard oil sample

[0025] Under the condition of avoiding light, dissolve excessive pure furfural in pure transformer oil, stir it magnetically for 5 minutes, and let it stand for 5 hours to prepare a furfural-saturated oil solution. The concentration of furfural in the solution is 353 mg / L.

[0026] Then 100ml of furfural-saturated oil solution was mixed with 100ml of pure transformer oil to form the first diluted furfural oil sample. Take 100ml of the first diluted furfural oil sample and mix it with 100ml of pure transformer oil to form the second diluted furfural oil sample.

[0027] Repeat the dilution ten times in sequence to prepare ten standard oil samples with concentration gradients, the furfural concentrations are 176mg / L, 88mg / L, 44mg / L, 22mg / L, 11mg / L, 5.5mg / L, 2.75mg / L , 1.38mg / L, 0.69mg / L, 0.34mg / L.

Embodiment 2

[0028] Embodiment 2: prepare the furfural water extract of standard oil sample

[0029] Get 70ml respectively from ten kinds of standard oil samples containing different concentrations of furfural prepared in Example 1, mix them with 7ml deionized water respectively in ten 100ml Erlenmeyer flasks according to the ratio of 10:1, and stir magnetically for 5min to make the extraction fully , and then poured them into 100ml centrifuge tubes respectively, centrifuged at 8500r / min for 5min, and took out the lower layer separation liquid as furfural water extract.

Embodiment 3

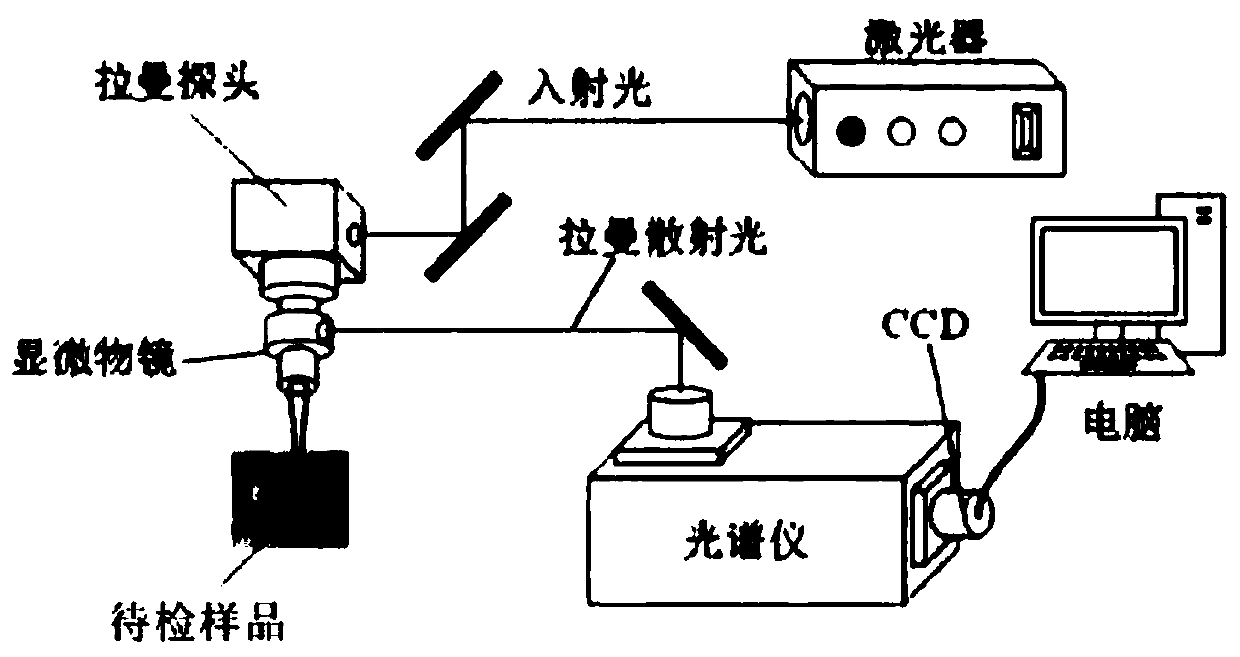

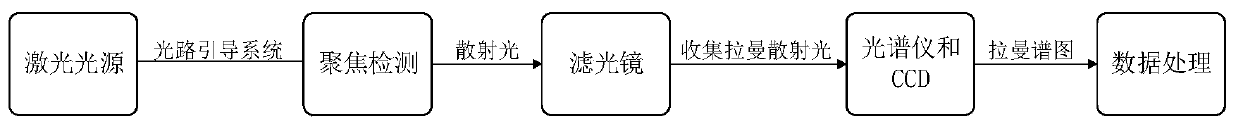

[0030] Embodiment 3: Determine the Raman characteristic peak of furfural

[0031] Choose a laser with a wavelength of 532nm, choose a slit width of 100μm, choose a 1200l / mm type grating, integrate time for 30s, and integrate twice.

[0032] Under the same experimental environment and conditions, for ten standard oil samples (furfural concentration is 176mg / L, 88mg / L, 44mg / L, 22mg / L, 11mg / L, 5.5mg / L, 2.75mg / L, 1.38 mg / L, 0.69mg / L, 0.34mg / L), pure furfural as a control and deionized water as a control were subjected to direct Raman detection, and their Raman spectra were obtained. Figure 4 The Raman spectra of the water extract of the standard oil sample with a furfural concentration of 176 mg / L, pure furfural as a control, and deionized water as a control are shown.

[0033] Make a preliminary judgment on the attribution of the Raman spectrum peaks. From the measured Raman spectrum, it can be seen that the Raman detection spectrum obtained by extraction with deionized wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com