Protective coating for micro-arc oxidation and preparation method thereof

A technology of micro-arc oxidation and protective coating, applied in the direction of coating, etc., can solve the problems of high partial discharge spark temperature, high oxidation breakdown voltage, long processing cycle, etc., and achieve good adhesion, no leakage, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

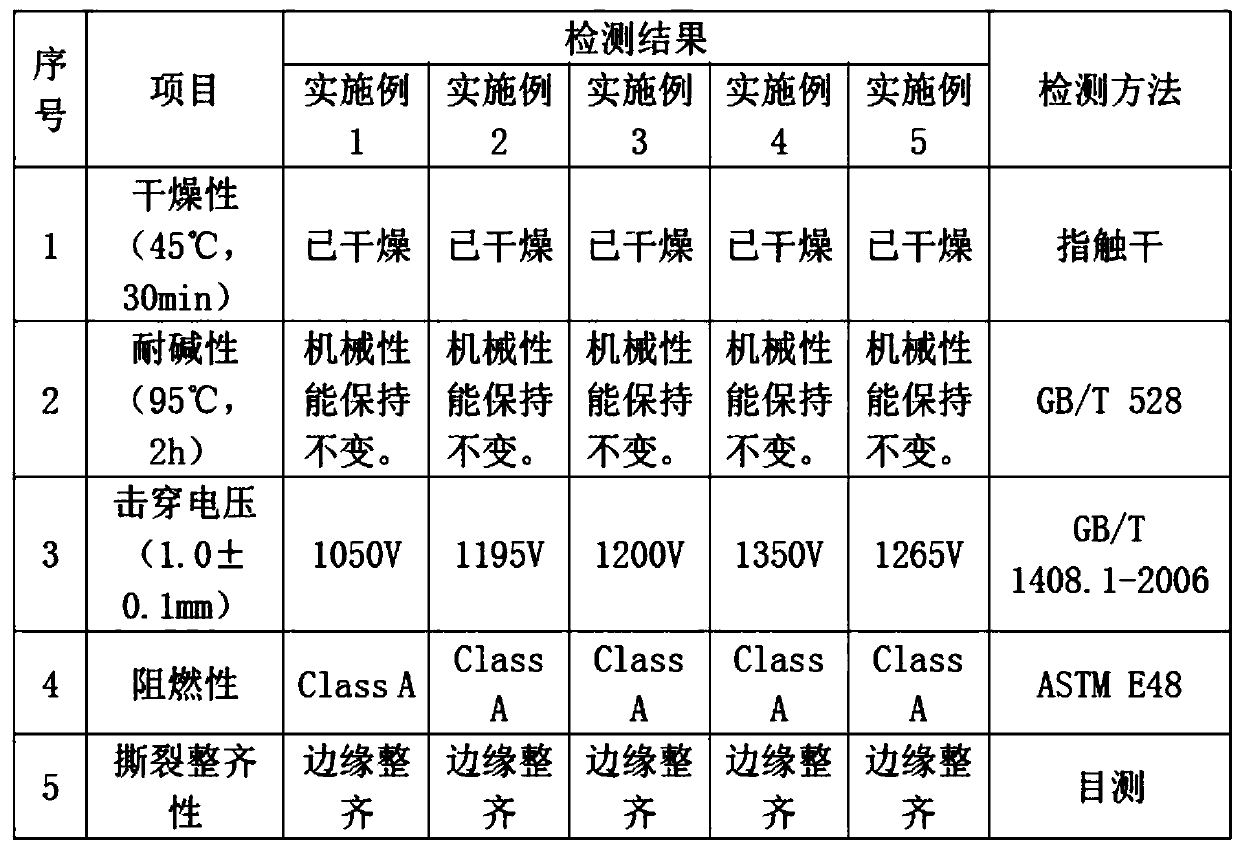

Examples

Embodiment 1

[0048] (1) Preparation of base resin

[0049] Pour 6% polyisobutylene and 15% SBS resin into their respective reaction kettles, respectively add 34% dimethyl carbonate and 45% butyl acetate for soaking, stir until evenly mixed, and obtain the base Material resin, spare;

[0050] (2) Preparation of modified silicone resin

[0051] Mix 98% of dihydroxy polydimethylsiloxane and 2% of silane coupling agent at 80°C and -0.1MPa vacuum for 60 minutes and then cool it down to room temperature to obtain a modified silicone resin. ;

[0052] Among them, the viscosity of dihydroxypolydimethylsiloxane is 5000mPa.S; the silane coupling agent is an aminosilane coupling agent.

[0053] (3) Add 44% base material resin into the movable tank, then add 8% modified silicone resin, 8% flame retardant, 2.7% fumed silica, and 0.6% dimethyl Base silicone oil, 0.3% defoamer, 1.5% color paste and 34.9% solvent are mixed, and a high-speed mixer is used to stir it evenly to obtain a mixed material;

...

Embodiment 2

[0057] (1) Preparation of base resin

[0058] Pour 8% polyisobutylene and 20% SBS resin into their respective reaction kettles, respectively add 30% dimethyl carbonate and 42% butyl acetate for soaking, stir until evenly mixed, and obtain the base Material resin, spare;

[0059] (2) Preparation of modified silicone resin

[0060] Mix 95% dihydroxy polydimethylsiloxane and 5% silane coupling agent at 120°C and -0.09MPa vacuum conditions for 30 minutes, then cool down to room temperature to obtain a modified silicone resin. ;

[0061] Among them, the viscosity of dihydroxypolydimethylsiloxane is 8000mPa.S; the silane coupling agent is vinyl silane coupling agent.

[0062] (3) Add 48% base material resin into the movable tank by mass percentage, then add 6% modified silicone resin, 7% flame retardant, 3% fumed silica, 0.3% dimethyl Base silicone oil, 0.4% defoamer, 2% color paste and 33.3% solvent are mixed, and a high-speed mixer is used to stir it evenly to obtain a mixed m...

Embodiment 3

[0066] (1) Preparation of base resin

[0067] Pour 7% polyisobutylene and 18% SBS resin into respective reaction kettles, respectively add 32% dimethyl carbonate and 43% butyl acetate for soaking, stir until evenly mixed, and obtain base Material resin, spare;

[0068] (2) Preparation of modified silicone resin

[0069] Mix 96% of dihydroxypolydimethylsiloxane and 4% of silane coupling agent at 100°C and -0.09MPa vacuum for 40 minutes and then cool it down to room temperature to obtain a modified silicone resin. ;

[0070] Among them, the viscosity of dihydroxypolydimethylsiloxane is 10000mPa.S; the silane coupling agent is propionyloxysiloxane.

[0071] (3) Add 46% base material resin into the movable tank, then add 7% modified silicone resin, 8% flame retardant, 3.6% fumed silica, 0.45% dimethyl Base silicone oil, 0.5% defoamer, 1.8% color paste and 32.65% solvent are mixed, and a high-speed mixer is used to stir it evenly to obtain a mixed material;

[0072] Among them...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com