Preparation method for peelable glue protection graph of capacitive touch screen

A capacitive touch screen and protection pattern technology, applied in the direction of electrical digital data processing, input/output process of data processing, instruments, etc., to achieve the effect of reducing precision requirements, saving costs, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

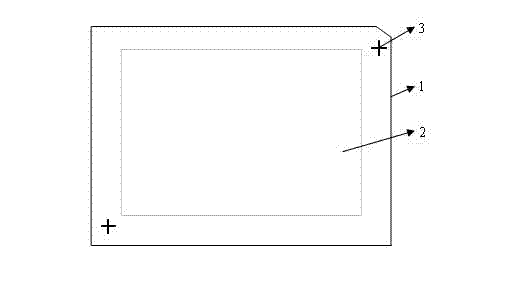

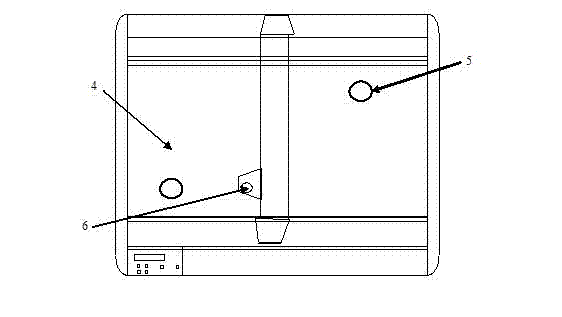

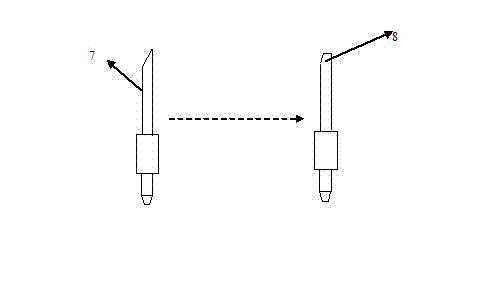

[0021] like Figure 1-4 shown.

[0022] like figure 1 As shown, a method for preparing a peelable adhesive protection pattern on a capacitive touch screen, the first step is to uniformly print a layer of peelable adhesive 2 on a glass substrate 1 with an ITO pattern, and the protection range of the peelable adhesive 2 is required to cover Cover the functional area of the entire capacitive screen, and at the same time do not cover the two cross marks 3 at the diagonal corners of the substrate 1. After printing, use an oven to dry the peelable glue 2; the second step is to print the peelable glue and dry the substrate ( figure 1 ) on the cutting machine ( figure 2 ) on the table 4, and it is required to use the two cross marks 3 on the substrate 1 to align the CCD lens 5 on the cutting machine, and then pass through the cutting machine ( figure 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com