Oily sewage drainage treatment process and device

A technology for treating process and sewage, which is applied in water/sewage treatment, biological water/sewage treatment, oxidized water/sewage treatment, etc. It can solve the problems of complex process flow, low treatment efficiency and large investment, and achieve excellent biological activation performance. , The effect of high treatment efficiency and less secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing:

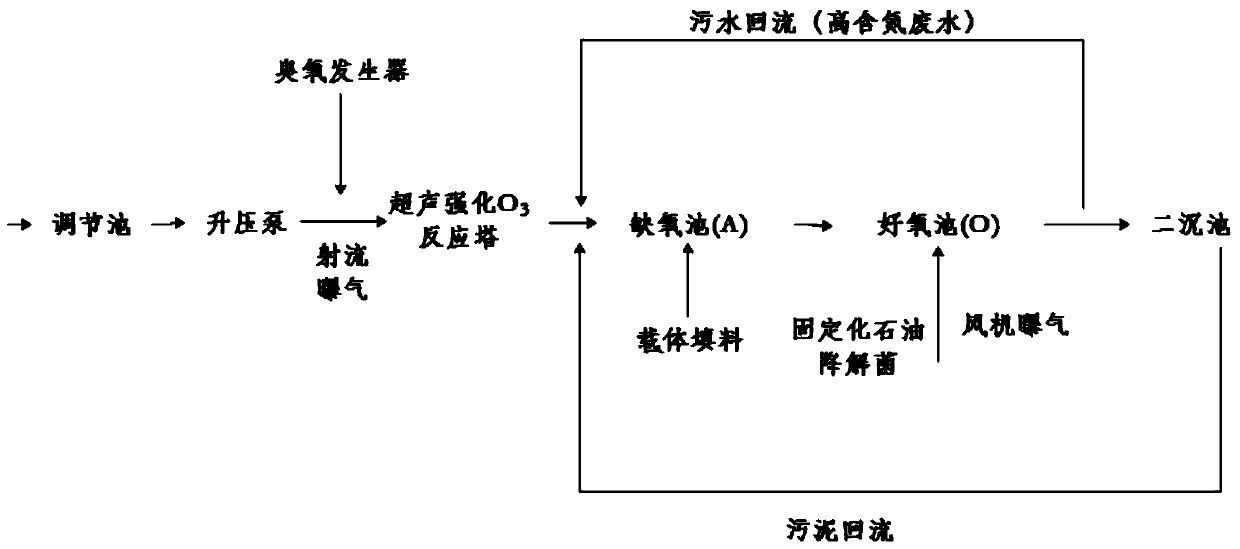

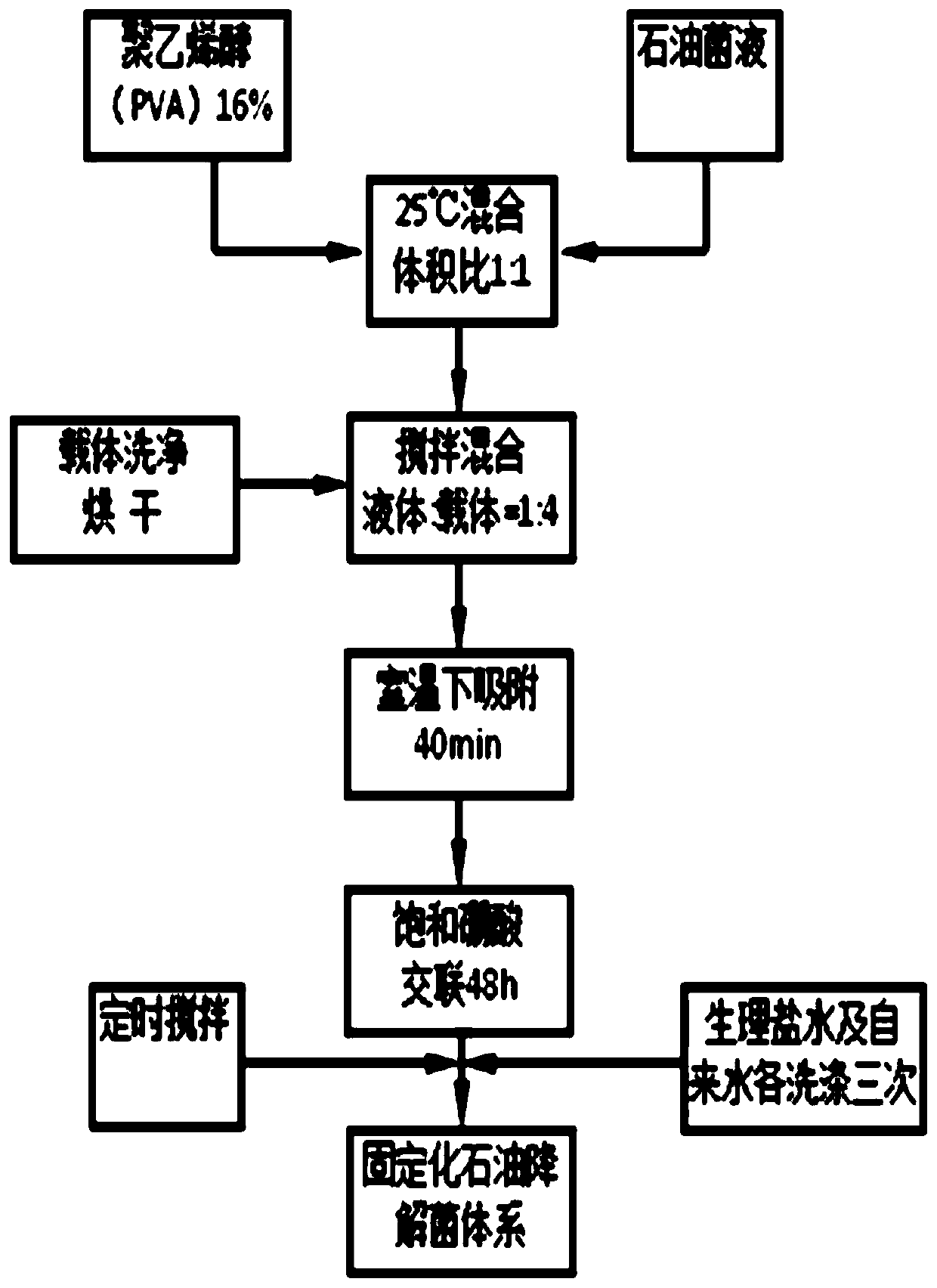

[0025] combined with figure 1 , a kind of oily sewage effluent treatment process comprises the following steps:

[0026] Step 1: After the oilfield sewage is settled and filtered, it flows into the adjustment tank, and the water quality, water quantity and water temperature are uniformly adjusted in the adjustment tank; the uniform adjustment of water quality and water temperature is conducive to more uniform sewage purification in the next step.

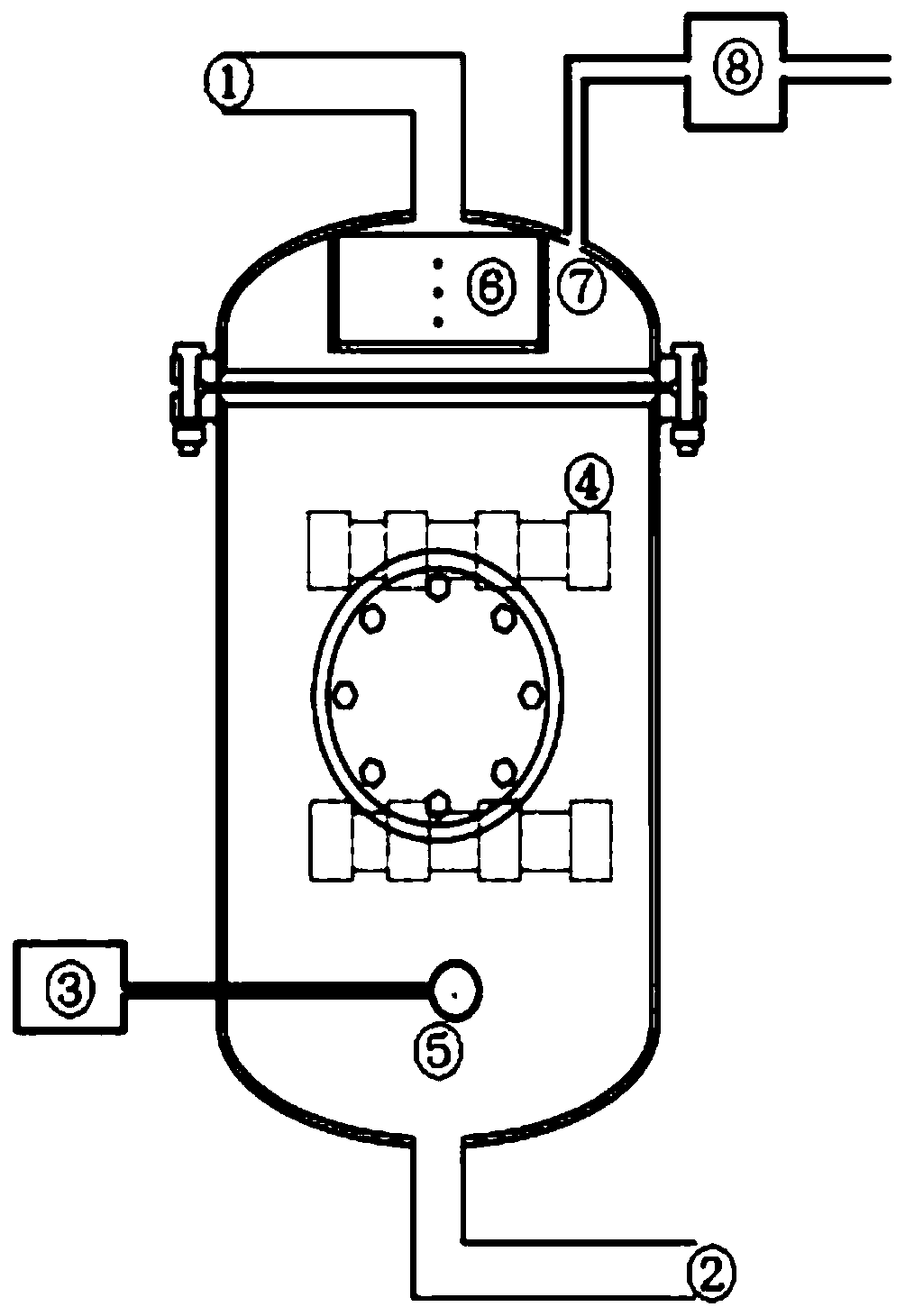

[0027] Step 2: The sewage treated in step 1 is lifted by the pump into the ultrasonic enhanced ozone reaction tower according to the designed flow rate, and the high-frequency sound waves in the tower are used to form mechanical oscillations to enhance ozone mass transfer, and ultrasonic cavitation is used to enhance OH production. The addition, substitution, electron transfer, bond breaking, etc. between OH and organic compound...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com