Flexible automatic wire connection device and method

A flexible and automatic technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve problems such as dimensional deformation, friction and collision, and affect the surface integrity and size of optical fiber filaments, so as to ensure surface integrity and dimensional accuracy, The effect of avoiding frictional contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: Splicing 30 optical fiber filaments with a diameter of 3 mm and a length of 500 mm

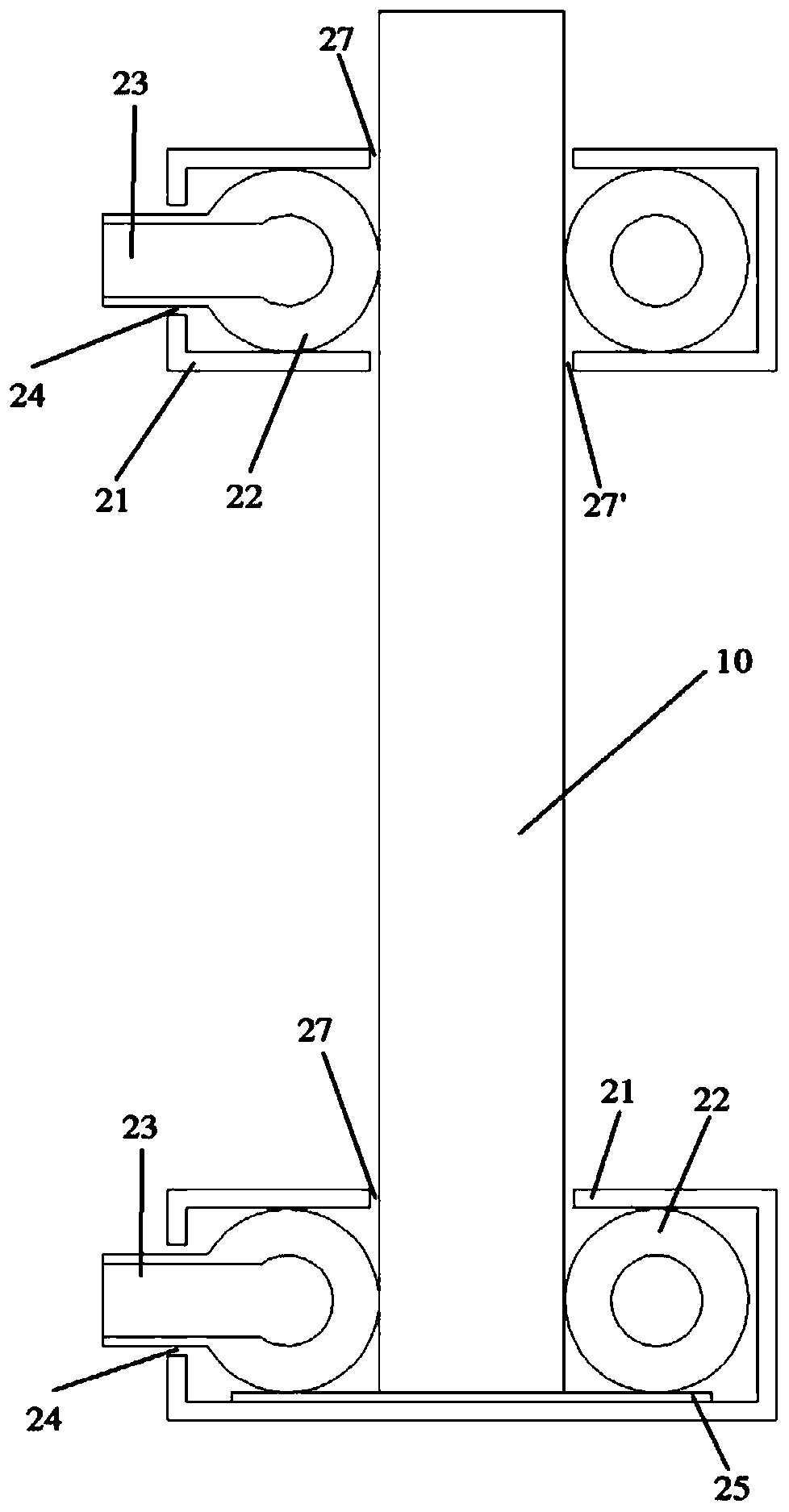

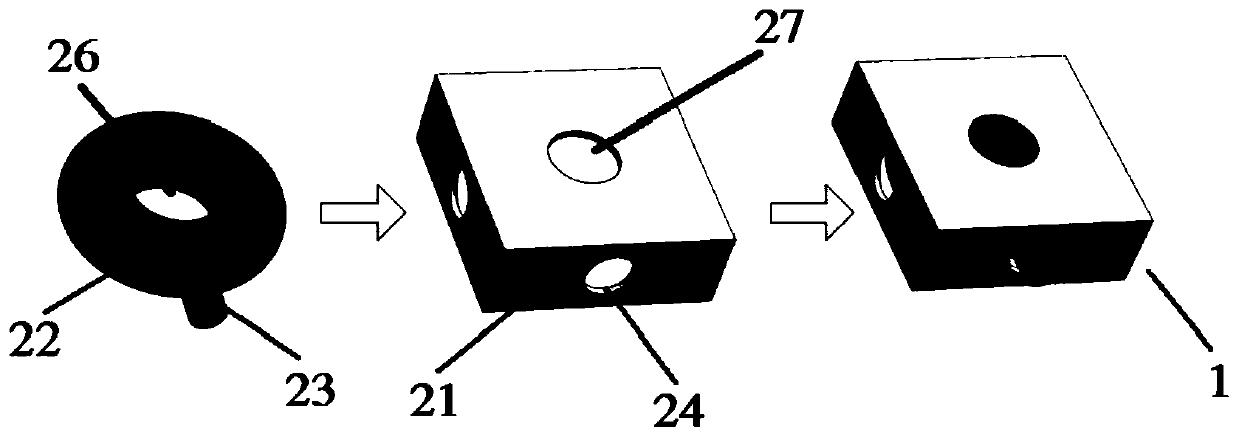

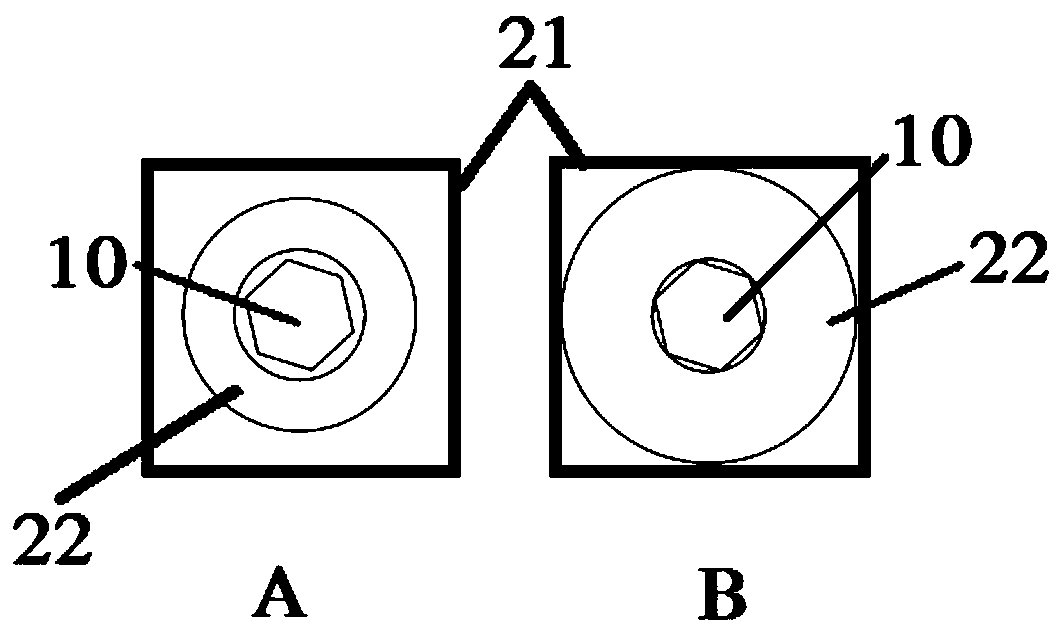

[0042] (1) Initial state setting: each flexible holder assembly 5 in the automatic wire splicing device of the present invention is provided with 30 flexible holders and 30 spokes. Adjust the distance between the spoke supports at the upper and lower ends of the automatic wire splicing device of the present invention, so that the distance between the soft capsule through holes in the upper and lower flexible clamper assemblies 5 is about 400mm; the diameter of the soft capsule through hole of the flexible clamper is adjusted at About 5mm.

[0043] (2) Wire splicing: After the initial state setting is completed, start the turntable 2, let it rotate and drive the rotation of the flexible gripper 1 at the same time, when the first flexible gripper unit corresponding to the upper and lower turns to the doffing of the target filament At the same time, the filaments fall into t...

Embodiment 2

[0046] Embodiment 2: Splicing 20 optical fiber filaments with a diameter of 3 mm and a length of 400 mm

[0047] (1) Initial state setting: each flexible holder assembly 5 in the automatic wire splicing device of the present invention is provided with 20 flexible holders and 20 spokes. Adjust the distance between the spoke supports at the upper and lower ends of the automatic wire splicing device of the present invention, so that the space between the soft capsule through holes in the upper and lower flexible clamper assemblies 5 is about 300 mm; the diameter of the soft capsule through hole of the flexible clamper is adjusted at About 5mm.

[0048] (2) Wire splicing: After the initial state setting is completed, start the turntable 2, let it rotate and drive the rotation of the flexible gripper 1 at the same time, when the first flexible gripper unit corresponding to the upper and lower turns to the doffing of the target filament At the same time, the filaments fall into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com