Vertical bar extending and back-adjusting installation method for precast concrete composite slab

A technology of prefabricated concrete and installation method, applied in the direction of floor slab, building material processing, building components, etc., can solve the problem of grout leakage at the joint of beam and plate, and achieve the effect of preventing grout leakage, reducing manual workload and avoiding collision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

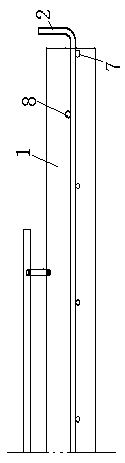

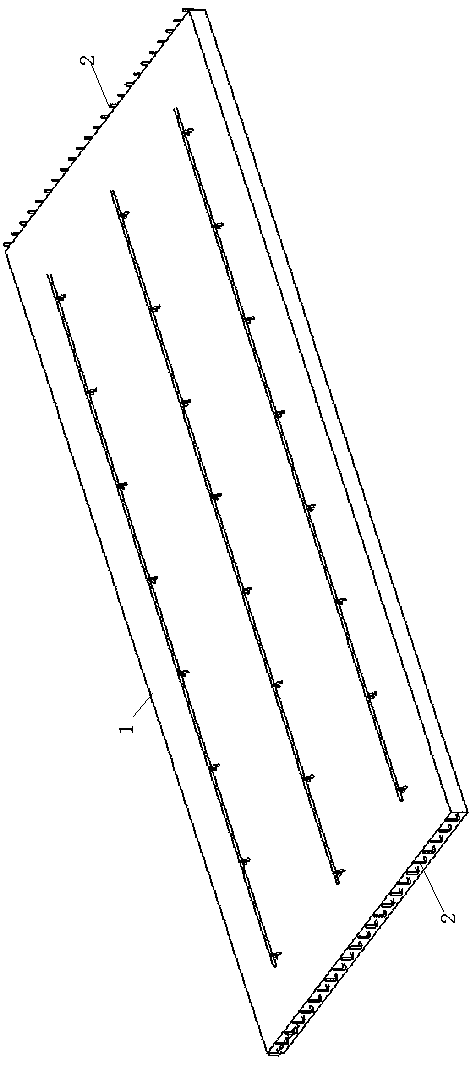

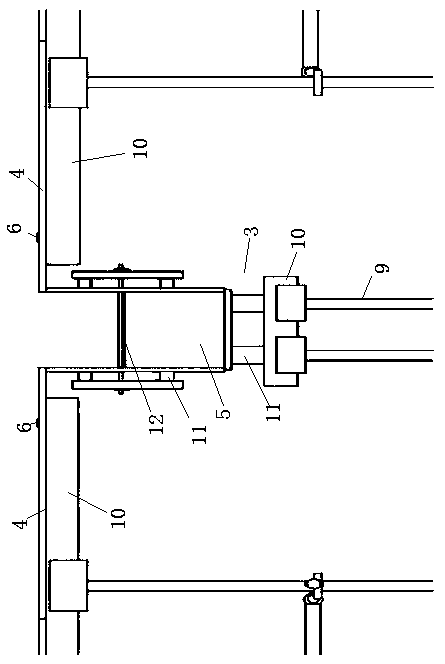

[0028] Such as Figure 1~11 As shown, an installation method for vertical reinforcement and callback of precast concrete laminated slabs, the installation method includes the following steps: (1) bending the beard tendons 2 at both ends of the laminated slab 1 upward by 90 degrees; (2) arranging the beam formwork 3 and wooden formwork 4, foam glue strips 6 are set on the upper surface of the wooden formwork at the edge of the beam forming cavity 5 of the beam forming cavity; (3) The beam forming cavity is placed with a reinforcement cage, and the beam reinforcement is first bound according to the traditional method, and the laminated board is transported Go to the site for vertical hoisting and installation. Because the beard tendons are bent in advance, even t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com