Sodium sulfate solution circulating fluidized bed evaporation device and operation method thereof

A technology of circulating fluidized bed and sodium sulfate solution, applied in forced circulation evaporators, chemical instruments and methods, evaporation, etc., can solve the problems of poor heat transfer performance and easy scaling, increase the core of vaporization, and promote mass transfer , the effect of good heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

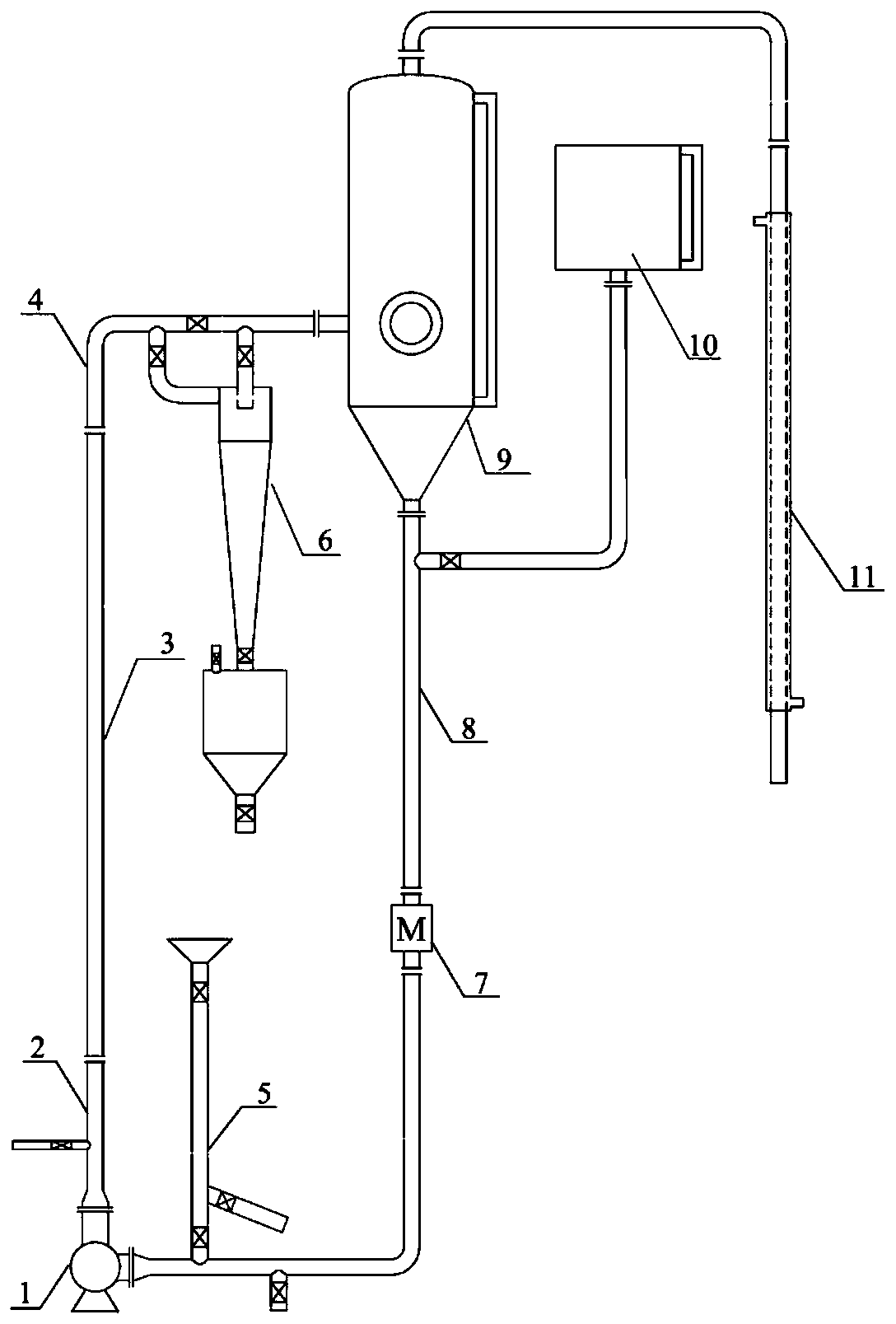

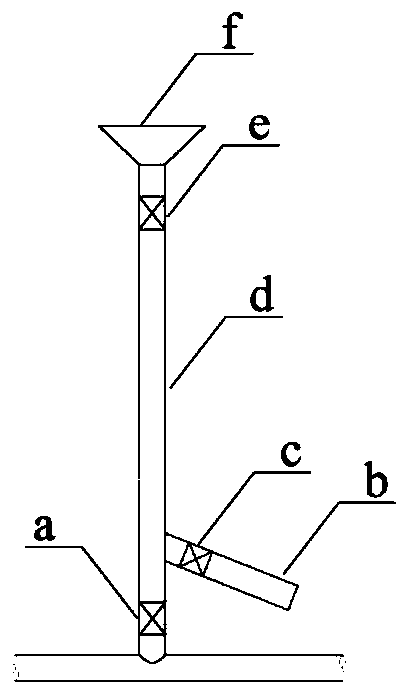

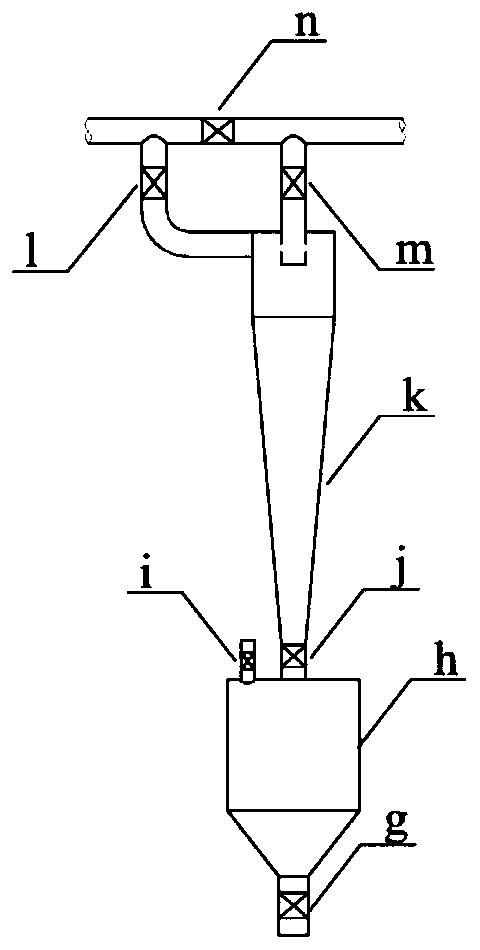

[0026] Such as figure 1 As shown, this embodiment discloses a sodium sulfate solution circulating fluidized bed evaporation device, which is made of 316L stainless steel, including a circulating pump 1, a second connecting pipeline 2, a heating pipe 3, and a first connecting pipeline 4 , On-line particle dosing device 5, on-line particle collection device 6, electromagnetic flowmeter 7, circulation pipe 8, evaporation chamber 9, header tank 10 and condenser 11.

[0027] The heating pipe 3 is arranged vertically, and the lower end of the heating pipe 3 is an inlet, and the upper end is an outlet, and the fluid flows upward along the heating pipe 3 . The outlet of the heating pipe 3 is connected to the inlet of the evaporation chamber 9 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com