High-brightness graphic composite substrate and manufacturing method thereof

A composite substrate and manufacturing method technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., to achieve the effects of avoiding easy oxidation, improving brightness, and increasing reflection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

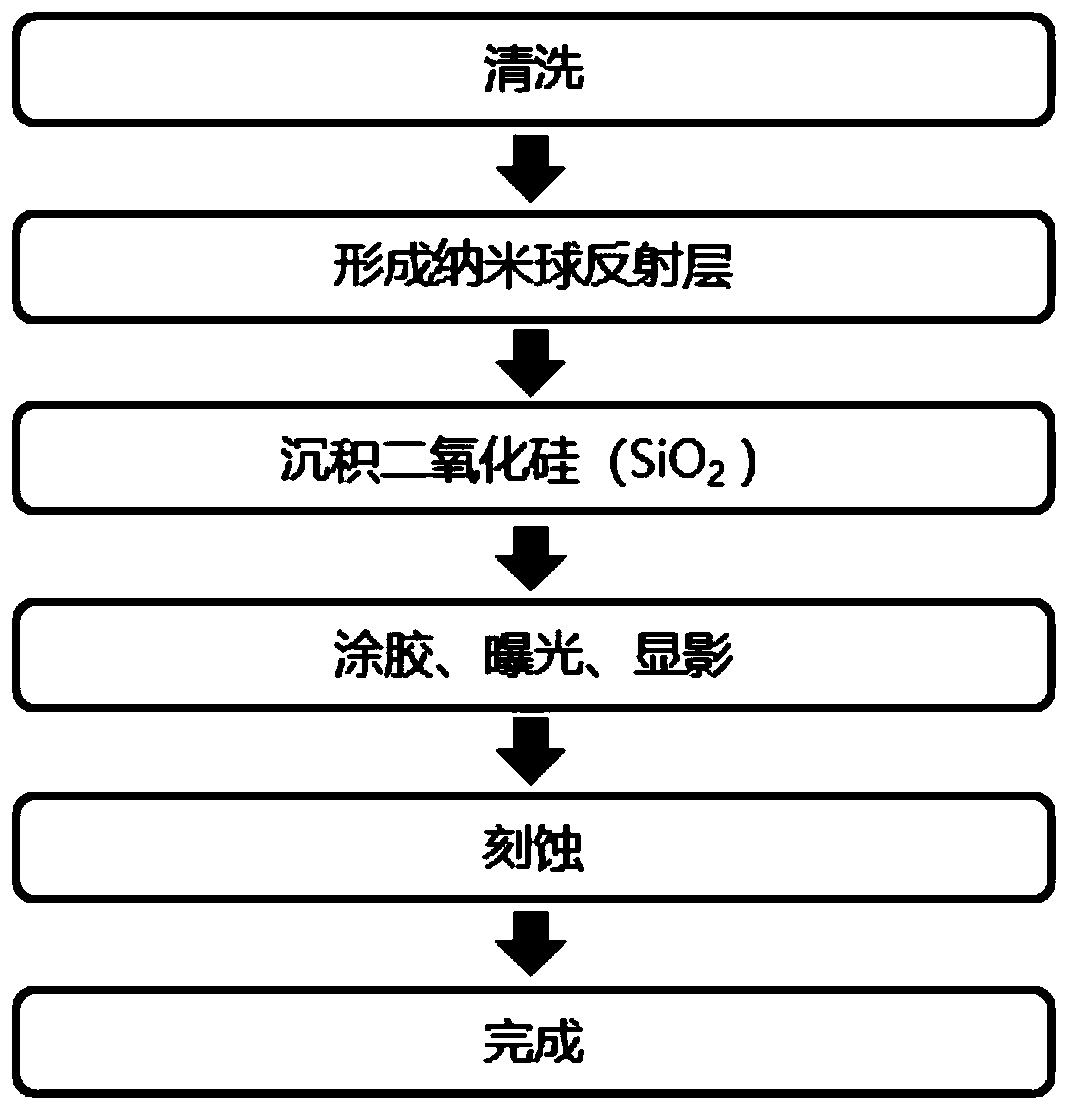

Method used

Image

Examples

Embodiment

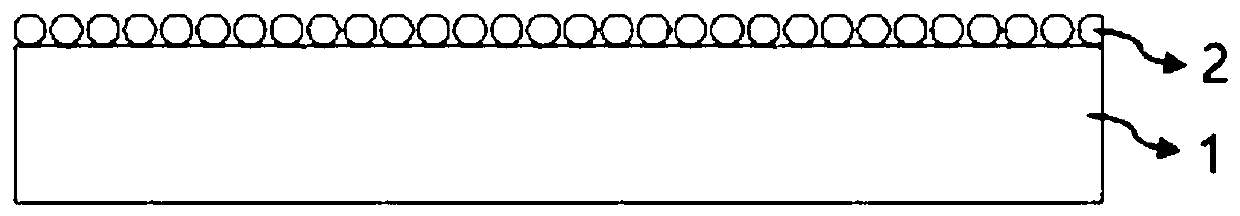

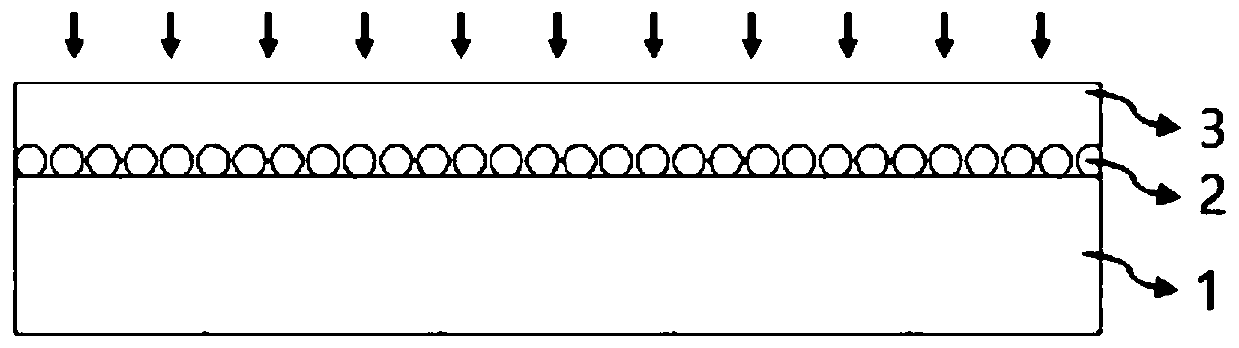

[0030] Embodiment: a kind of high-brightness patterned composite substrate, such as Image 6 , Figure 7 As shown, a sapphire flat plate 1 is included, and a group of composite patterns are distributed on the sapphire flat plate 1, and the composite patterns include a nanosphere reflective layer 2 and SiO coated on the surface of the nanosphere reflective layer 2 2 Coating6. The nanospheres in the nanosphere reflective layer 2 are made of metal, specifically Au, Ag, Ni, Pt, Mg, Fe, Cu, Ca, Ti, Al or a mixture of several metals. The particle size is 50-500nm. In order to prevent the oxidation of metal materials and prevent the reaction with the deposition solution during deposition, the surface of the nanospheres is also coated with a layer of SiO 2 or TiO 2 . In this patterned composite substrate structure, the nanospheres form a yurt-shaped microstructure in the composite pattern, and the light can emit light after multiple reflections in the yurt structure. The chip sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com