A kind of preparation method and application of high-entropy alloy solder

A technology of high-entropy alloys and brazing filler metals, applied in metal processing equipment, welding equipment, manufacturing tools, etc., can solve problems such as insufficient bonding of metal film layers and inability to apply high-temperature applications, so as to reduce re-reduction processing steps and shorten production Appropriate effect of period and particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] (1) Weighing and ball milling: in a glove box where argon exists, weigh 25% of Ni powder, 25% of Cr powder, 25% of Co powder, and 25% of Fe powder by mole percentage, wherein the Ni powder The diameter is 1.6mm, the particle size of Cr powder is 1.6mm, the particle size of Co powder is 1.6mm, and the particle size of Fe powder is 1.6mm. 5:1, ball milling speed is 1400rpm, ball milling bead diameter is 8mm, carry out high energy ball milling 9h with SPEX 8000D high energy ball mill, obtain the product after ball milling;

[0079] (2) Discharge plasma sintering molding: collect the ball-milled product, put it into a mold after cooling, then use a pressure of 40 MPa under a vacuum atmosphere, and raise the temperature from room temperature to 1000 °C at a first heating rate of 100 °C / min, and then Raise the temperature to 1100°C at the second heating rate of 50°C / min, hold for 6 minutes and sinter;

[0080] (3) Polishing and cleaning: The high-entropy alloy obtained by si...

Embodiment 2

[0084] The difference between this embodiment and Embodiment 1 is that the sintered SiC ceramics are replaced by 6H-SiC ceramics.

[0085] The experimental results show that the contact angle of high entropy alloy solder CoCrFeNi on 6H-SiC ceramics is 32°.

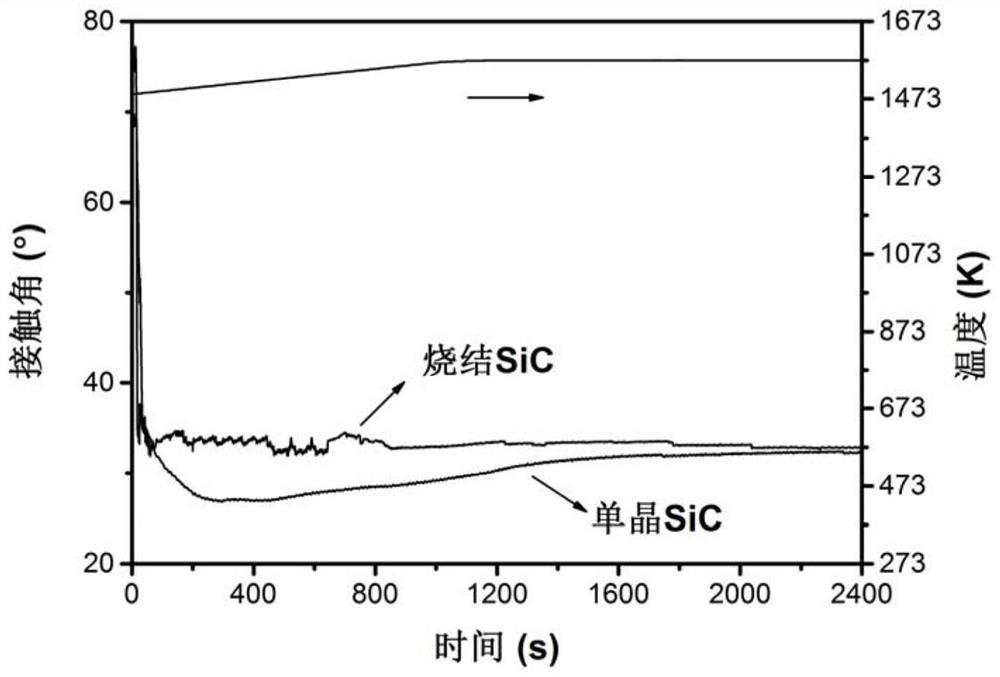

[0086] figure 1 Contact angle diagrams of the high-entropy alloy CoCrFeNi prepared for Example 1 on sintered SiC (Example 1) and 6H-SiC (Example 2, that is, the curve marked with single crystal SiC in the figure) at 1300°C. It can be seen from the figure that when the temperature rises to the melting point of CoCrFeNi alloy, its contact angle on SiC ceramics decreases rapidly to less than 40°, indicating that CoCrFeNi high-entropy alloy and SiC ceramics have excellent wettability. On the other hand, the contact angle of CoCrFeNi alloy on sintered SiC or single crystal 6H-SiC is very small, indicating that the type of SiC ceramic has little effect on the contact angle.

Embodiment 3

[0088] The difference between this embodiment and embodiment 1 is that 33.3% of Cr powder, 33.3% of Co powder, 16.7% of Fe powder, and 16.7% of Ni powder are weighed by mole percentage.

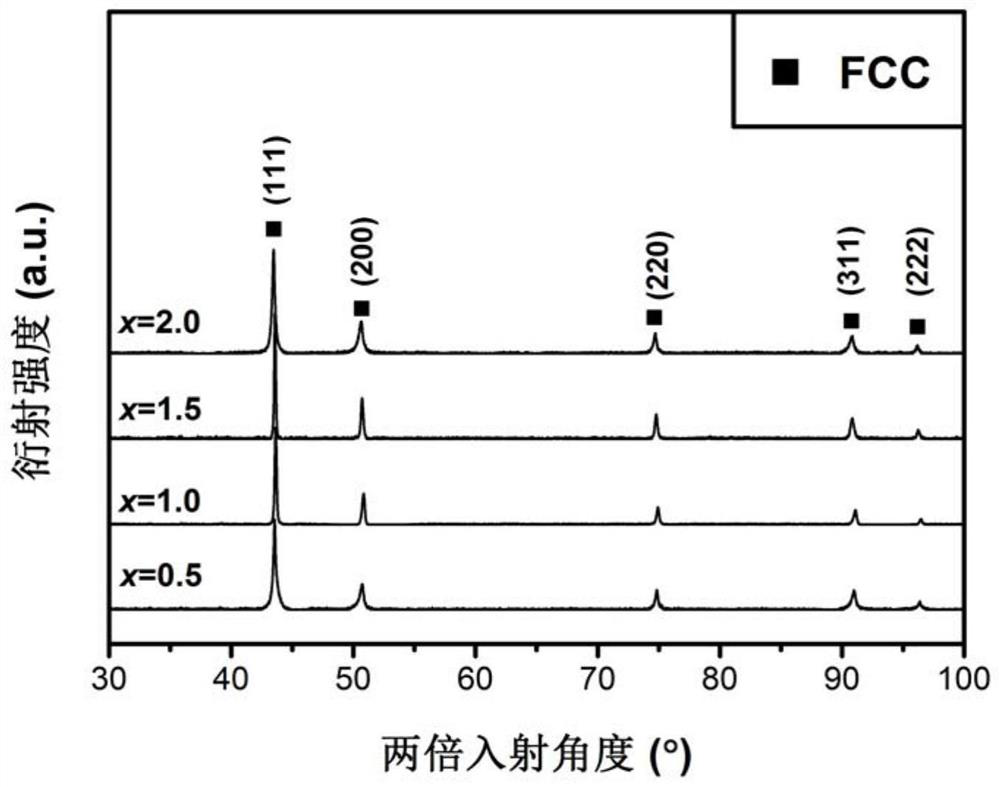

[0089] The experimental results show that the high entropy alloy solder CoCr(FeNi) 0.5 The contact angle of sintered SiC is 40°, and the change of element content ratio is analyzed by XRD pattern. High entropy alloy solder CoCr(FeNi) 0.5 The phase composition is a face-centered cubic single-phase structure, and its melting point is between 1250-1300 °C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com