High-temperature-resistant salt-resistant copolymer-type water-based drilling fluid loss reducing agent as well as preparation method and application thereof

A technology of water-based drilling fluid and fluid loss control agent, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of inapplicability of fluid loss control agent, improve the performance of high temperature resistance and salt resistance, and improve the preparation process Simple, effective in reducing fluid loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

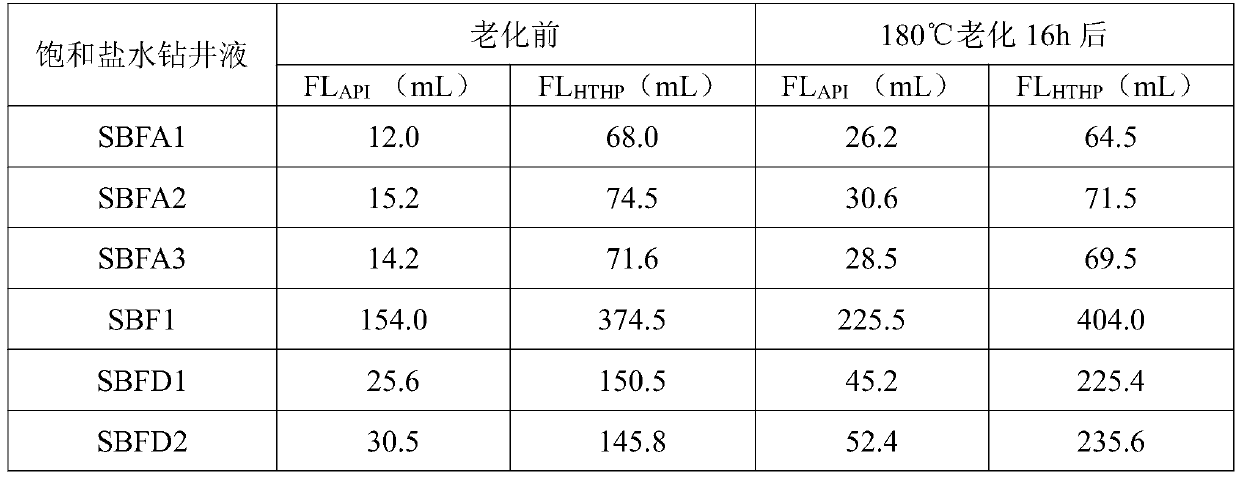

Examples

Embodiment 1

[0016] A preparation method of a high-temperature-resistant and salt-resistant copolymer type water-based drilling fluid fluid loss reducer, comprising the following steps:

[0017] (1) 5 parts of sodium p-styrene sulfonate monomer, 4.5 parts of N, N-dimethylacrylamide monomer and 0.5 part of itaconic acid monomer were dissolved in 35 parts of distilled water in sequence according to the mass, and the pH value was adjusted to 5. Stir evenly and heat up to 60°C to obtain a mixed solution;

[0018] (2) Take by weighing the initiator ammonium persulfate equivalent to 0.5% of the total monomer mass of step (1) and be dissolved in 5 parts of distilled water, stir to obtain the initiator solution;

[0019] (3) Add the initiator solution dropwise to the mixed solution obtained in step (1) at a uniform speed for 20 minutes. After the dropwise addition, heat up to 65° C. and continue the reaction for 5 hours to obtain a viscous liquid, freeze-dry, Pulverized to obtain high temperature...

Embodiment 2

[0021] A preparation method of a high-temperature-resistant and salt-resistant copolymer type water-based drilling fluid fluid loss reducer, comprising the following steps:

[0022] (1) Dissolve 7 parts of sodium p-styrene sulfonate monomer, 2.5 parts of acrylamide monomer and 1 part of maleic acid monomer in 33 parts of distilled water in sequence according to the mass, adjust the pH value to 8, stir evenly and heat up to 55°C, a mixed solution was obtained;

[0023] (2) Take by weighing 2.0% initiator potassium persulfate equivalent to step (1) monomer gross mass and be dissolved in 7 parts of distilled water, stir to obtain initiator solution;

[0024] (3) Add the initiator solution dropwise to the mixed solution obtained in step (1) at a constant speed for 40 minutes. After the dropwise addition, heat up to 80° C. and continue the reaction for 2 hours to obtain a viscous liquid, freeze-dry, Pulverize to obtain high temperature resistant and salt resistant copolymer type w...

Embodiment 3

[0026] A preparation method of a high-temperature-resistant and salt-resistant copolymer type water-based drilling fluid fluid loss reducer, comprising the following steps:

[0027] (1) Dissolve 6 parts of sodium p-styrene sulfonate monomer, 3.5 parts of N, N-diethylacrylamide monomer and 0.5 part of fumaric acid monomer in 35 parts of distilled water in sequence according to the mass, and adjust the pH value to 6. Stir evenly and heat up to 60°C to obtain a mixed solution;

[0028] (2) Take by weighing 1.0% of the initiator azobisisobutylamidine hydrochloride equivalent to the total mass of the monomers in step (1) and dissolve it in 6 parts of distilled water, and stir to obtain the initiator solution;

[0029] (3) Add the initiator solution dropwise to the mixed solution obtained in step (1) at a constant speed for 30 minutes. After the dropwise addition, heat up to 70°C and continue the reaction for 3 hours to obtain a viscous liquid and freeze it. After being dried and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com