Method for preparing pentamethyldipropylene triamine

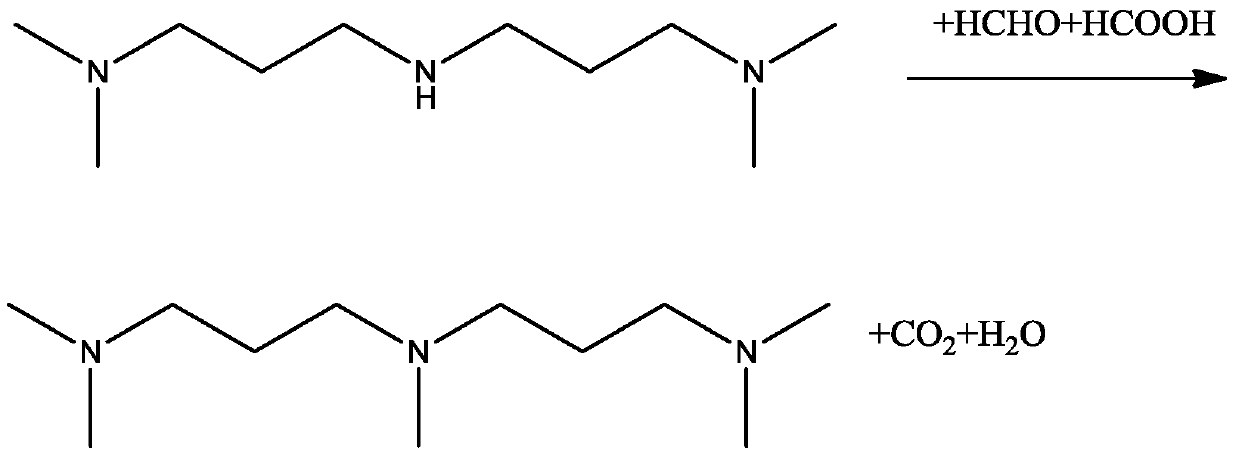

A technology for pentamethyldipropylenetriamine and dimethylaminopropylamine, which is applied in the preparation of amino compounds from amines, the preparation of carboxylic acid nitrile, the preparation of amino compounds, etc., can solve the problems of many by-products, difficult hydrogenation, and raw material methylamine. odor and other problems, to achieve the effect of accelerating hydrogenation rate, reasonable acidity distribution, and improving dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Preparation of 1# modified carrier:

[0052] Spherical γ-Al 2 o 3 (particle size 3mm, specific surface area 280m 2 / g) Calcined at 450°C for 4h. Prepare ammonium fluorosilicate and niobium nitrate with 100ml deionized water containing 5g SiO 2 , 1 g Nb 2 o 5 The immersion solution, and then heated to 90 ° C to form a uniform solution, 94g γ-Al 2 o 3 Add it to the impregnation solution, impregnate it at 90°C for 12 hours, bake it in an oven at 120°C for 12 hours; finally move it to a muffle furnace, heat it up to 500°C at 3°C / min and bake it for 8 hours in an air atmosphere to obtain a mass containing Fraction 5% SiO 2 +1%Nb 2 o 5 +94%γ-Al 2 o 3 modified carrier.

[0053] Preparation of 1# supported palladium-based catalyst precursor:

[0054] Use 80ml of deionized water to prepare a nitrate impregnation solution containing 4g of palladium, 1g of zinc, and 0.3g of rhenium, heat it to 80°C to form a homogeneous solution, then add 94.7g of 1# modified carrier...

Embodiment 2

[0056] Preparation of 2# modified carrier:

[0057] Spherical γ-Al 2 o 3 (particle size 3mm, specific surface area 280m 2 / g) Calcined at 400°C for 8h. Prepare ammonium fluorosilicate and niobium nitrate with 120ml deionized water containing 10g SiO 2 , 0.5g Nb 2 o 5 immersion solution, and then heated to 80 ° C to form a uniform solution, 89.5g γ-Al 2 o 3 Add it to the impregnation solution, impregnate it at 80°C for 16 hours, bake it in an oven at 110°C for 8 hours; finally move it to a muffle furnace, heat it up to 450°C at 2°C / min and bake it for 8 hours in an air atmosphere to obtain a mass containing Fraction 10% SiO 2 +0.5%Nb 2 o 5 +89.5%γ-Al 2 o 3 modified carrier.

[0058] Preparation of 2# supported palladium-based catalyst precursor:

[0059] Use 100ml of deionized water to prepare a nitrate impregnation solution containing 10g of palladium, 0.5g of zinc, and 0.2g of rhenium, heat it to 90°C to form a homogeneous solution, then add 89.3g of 2# modified...

Embodiment 3

[0061] Preparation of 3# modified carrier:

[0062] Spherical γ-Al 2 o 3 (particle size 3mm, specific surface area 280m 2 / g) Calcined at 500°C for 4h. Prepare ammonium fluorosilicate and niobium nitrate with 80ml deionized water containing 2g SiO 2 , 5g Nb 2 o 5 immersion solution, and then heated to 85 ° C to form a homogeneous solution, 93g γ-Al 2 o 3 Add to the impregnating solution, impregnate at 85°C for 24h, bake in an oven at 100°C for 12h; finally move to a muffle furnace, heat up to 300°C at 2°C / min and bake for 8 hours in an air atmosphere to obtain the mass fraction 2% SiO 2 +5%Nb 2 o 5 +93%γ-Al 2 o 3 modified carrier.

[0063] Preparation of 3# supported palladium-based catalyst precursor:

[0064] Use 50ml of deionized water to prepare a nitrate dipping solution containing 2g of palladium, 0.8g of molybdenum, and 1g of chromium, heat it to 90°C to form a homogeneous solution, then add 96.2g of 3# modified carrier, immerse at 90°C for 8h, and then at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com