A method for removing and recovering water-soluble salt in secondary aluminum ash

A technology of water-soluble salt and secondary aluminum, applied in separation methods, general water supply saving, chemical instruments and methods, etc., can solve the problems of poor comprehensiveness of desalination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

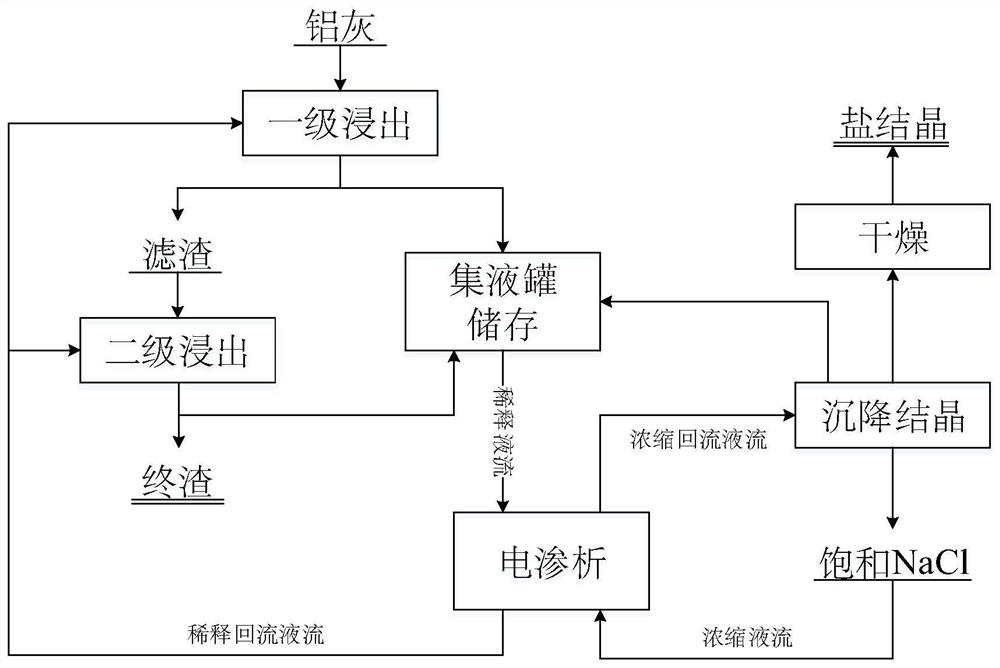

Image

Examples

Embodiment 1

[0028] A method for removing and recovering water-soluble salts in secondary aluminum ash includes the following steps:

[0029] S1. Put the secondary aluminum ash into a ball mill for fine grinding, and after passing through a 60-mesh sieve, return the large particles of aluminum that cannot be ground back to the primary aluminum ash smelting furnace to recover aluminum, and collect the fine ash under the sieve for use;

[0030] S2. Put the fine ash in S1 into a first-stage reaction tank at a liquid-to-solid mass ratio of 7:1 and mix with water, stir thoroughly at a rate of 250r / min, control the temperature in the reaction tank to be constant at 60°C, and reduce the gas generated in the reaction tank Into the ammonia absorption tower, after leaching for 120 minutes, the reaction liquid in the reaction tank is filtered and separated, the filtrate is sent to the collecting tank, and the filter residue is sent to the secondary reaction tank;

[0031] The filter residue in S3 and S2 is ...

Embodiment 2

[0039] S1. Put the secondary aluminum ash into a ball mill for fine grinding, and after passing through a 60-mesh sieve, return the large particles of aluminum that cannot be ground back to the primary aluminum ash smelting furnace to recover aluminum, and collect the fine ash under the sieve for use;

[0040] S2. Put the fine ash in S1 into the first-stage reaction tank at a liquid-solid mass ratio of 14:1 and mix with water, stir fully at a rate of 300r / min, control the temperature in the reaction tank to be constant at 90°C, and reduce the gas generated in the reaction tank Into the ammonia absorption tower, after 240 minutes of leaching, the reaction liquid in the reaction tank is filtered and separated, the filtrate is sent to the collecting tank, and the filter residue is sent to the secondary reaction tank;

[0041] The filter residue in S3 and S2 is mixed with water in the secondary reaction tank at a liquid-to-solid mass ratio of 8:1, fully stirred at a rate of 300r / min, an...

Embodiment 3

[0049] S1. Put the secondary aluminum ash into a ball mill for fine grinding, and after passing through a 60-mesh sieve, return the large particles of aluminum that cannot be ground back to the primary aluminum ash smelting furnace to recover aluminum, and collect the fine ash under the sieve for use;

[0050] S2. Put the fine ash in S1 into a first-stage reaction tank at a liquid-solid mass ratio of 10:1, mix with water, stir fully at a rate of 280r / min, control the temperature in the reaction tank to be constant at 75°C, and reduce the gas generated in the reaction tank Introduce into the ammonia absorption tower, after leaching for 180 minutes, the reaction liquid in the reaction tank is filtered and separated, the filtrate is sent to the collecting tank, and the filter residue is sent to the secondary reaction tank;

[0051] The filter residue in S3 and S2 is mixed with water in the secondary reaction tank at a liquid-to-solid mass ratio of 5:1, fully stirred at a rate of 270r / m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com