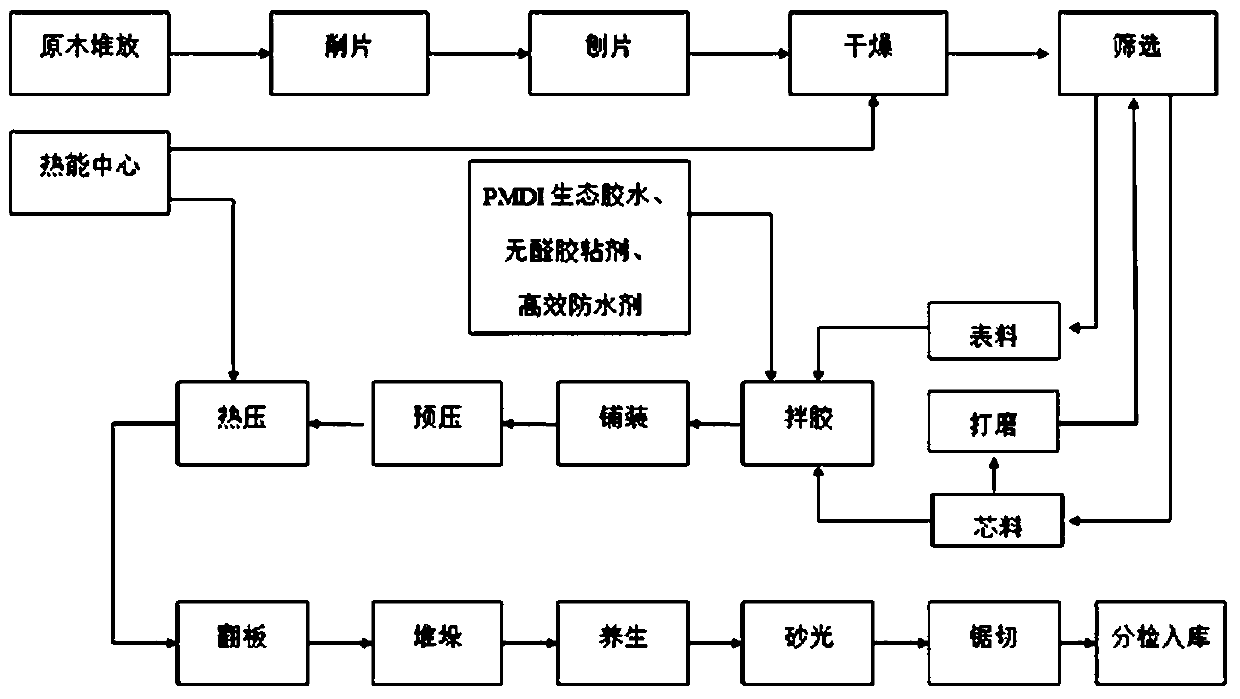

Preparation technology for zero-formaldehyde light particle board

A light-weight granule and preparation technology, which is applied in the direction of manufacturing tools, wooden veneer joints, flat products, etc., can solve the problems of formaldehyde poisoning, human body hazards, etc., and achieve strong waterproof ability, high safety, and good thermosetting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Table 1: Performance indicators of zero-formaldehyde moisture-proof particle board

[0048] Test items Test results Moisture content / % 6.8 In-board density deviation / % -1.5,+4.5 Static Bending Strength / (MPa) 14.8 Elastic modulus / (MPa) 2230 Internal bonding strength / (MPa) 0.57 Surface bonding strength / (MPa) 0.98 2h water absorption thickness expansion rate / % 6.7 Formaldehyde emission / (mg / m3) 0.043

Embodiment 2

[0050] Table 2: Test data of PMDI ecological glue:

[0051] Product name: Polymethylene polyphenylisocyanate

[0052] Test items Test results Exterior brown liquid Viscosity(25℃) / (mPa·s) 206 Isocyanate content (-NCO) / % 31.14 Hydrolyzed Chlorine / % 0.04 acidity / % 0.0034 Density(25℃) / (g / cm^3) 1.233 Iron content / (ug / g) 3

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com