Stone plastic floor and processing method thereof

A processing method and stone-plastic floor technology, applied in the field of building decoration materials, can solve problems such as unfavorable environmental protection, high toughness, wrinkles or deformation, etc., and achieve the effects of being beneficial to weight-limited use, good elastic recovery, and strong elastic recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

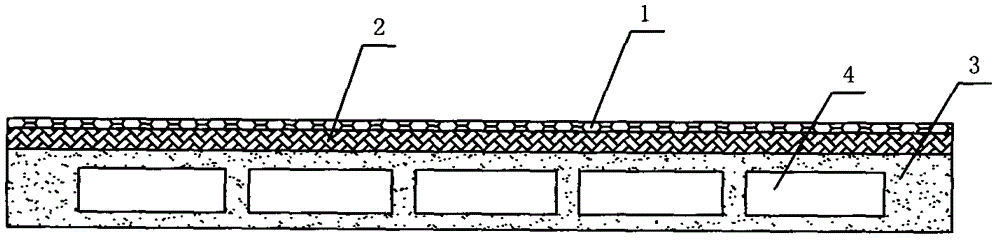

[0032] Attached below figure 1 The present invention is further described:

[0033] A stone-plastic floor according to the present invention consists of a bottom layer 3 , a surface layer 2 and a UV coating 1 . Among them, the bottom layer 3 is made of polyvinyl chloride resin and marble stone powder as the supporting body. The polyvinyl chloride resin and marble stone powder are mixed and processed at a weight percentage of 20%: 80%, which is not only compact in texture, but also light in weight and impact resistant. it is good. In order to reduce the weight of the bottom layer 3, a plurality of lightening holes 4 arranged horizontally are arranged on the bottom layer 3, and the lightening holes 4 run through the bottom layer 3 along the extending direction of the length of the stone-plastic floor. The surface layer 2 is attached to the top surface of the bottom layer 3, the surface layer 2 is a solid wood veneer, the surface of the solid wood veneer is provided with artifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com